Get Schooled on Mold Material Selection

The evolution of pre-hardened mold steels was presented during the "Global Advances in Pre-hardened Mold Steels" webinar by International Mold Steel last month, and audience members walked away learning these five facts about mold steels.

The evolution of pre-hardened mold steels was presented during the "Global Advances in Pre-hardened Mold Steels" webinar presented by International Mold Steel last month. Executive Vice President and General Manager Tom Schade and National Sales Manager Paul Britton teamed up to compare the differences and advantages of newer pre-hardened materials versus materials from the past, provide insight into how choosing the right material will lower the costs of the tool, review the advantages of using a pre-hard material versus a harden-able material, and share how Europe and Asia have evolved in different directions and how the U.S. started Euro-centric, but has evolved to a globalized view.

Audience members walked away learning five facts about mold steels:

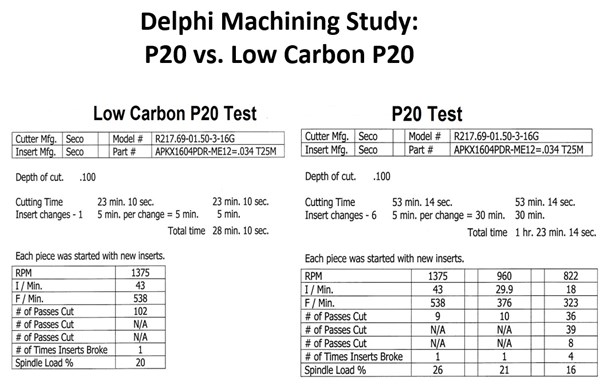

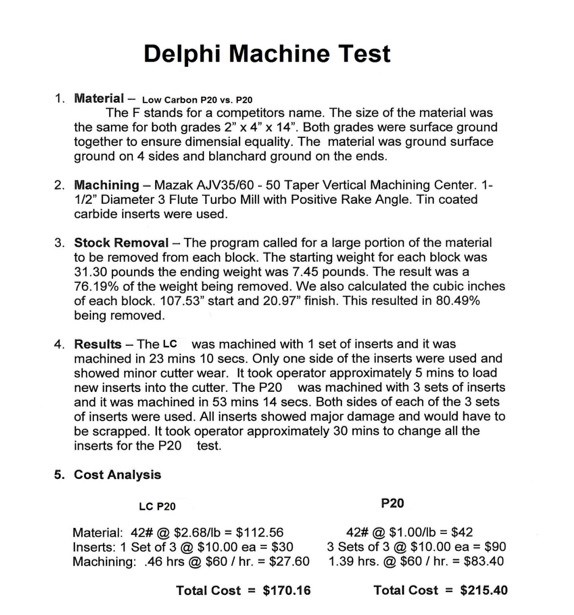

1. Choosing the right steel can save time and money.

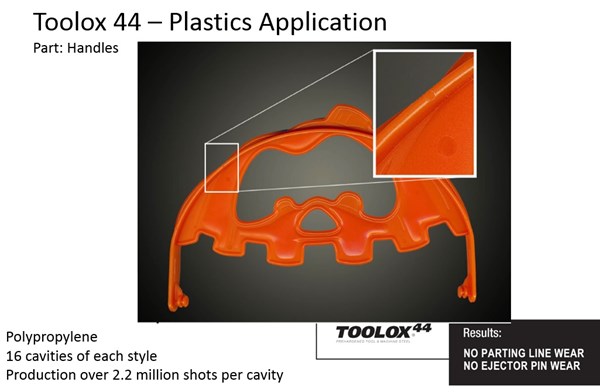

2. New pre-hard materials are easier to machine, weld, and do not require stress relieving.

3. There are better P20 steels on the market today.

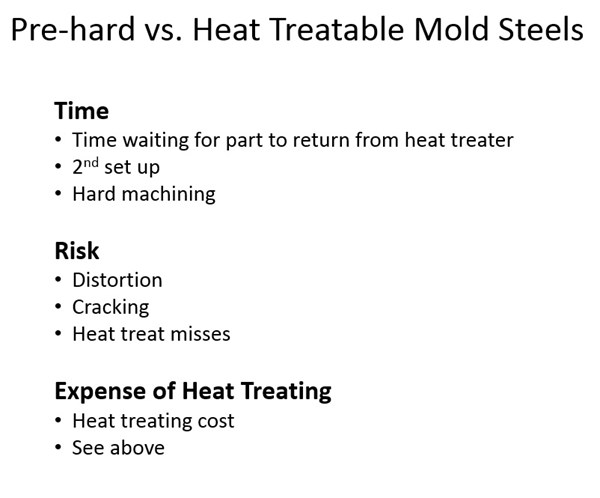

4. Why go through the cost of heat treating a steel, when the production quantities justify using a pre-hard?

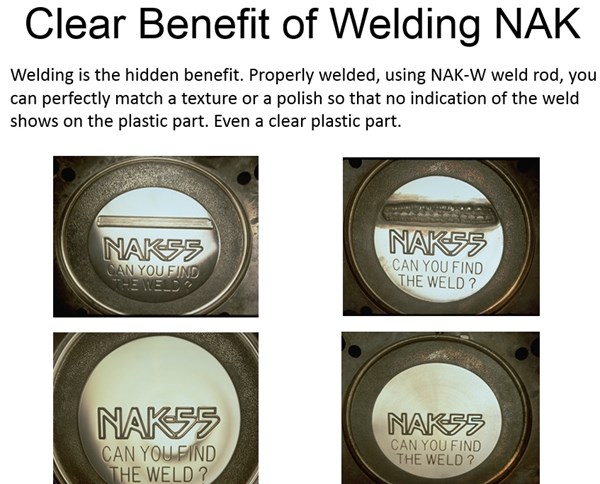

5. Can you find the weld? Nak 55 and Nak 80 offer people no evidence that the part was welded.

You can view this webinar now by clicking here. Then be sure to check out MMT's webinar archives, as well as a list of upcoming webinars.

Related Content

-

MMT Chats: A More Modern NPE “Made for You”

The Plastics Industry Association is making NPE 2024 a “can’t miss”’ experience with more of everything – education, exhibitors and networking! The PLASTICS Industry Association Chief Operating Officer Glenn Anderson and Director of Trade Show Marketing Damaris Piraino share what’s in store for attendees of next year’s May 6-10, 2024 in Orlando, Florida.

-

VIDEO: What You Need to Know about the R&D Tax Credit Today

A team member from Strike Tax Advisory reviews the tax changes that are impacting the R&D credits for mold builders.

-

Think Safety: Eliminate Hazards Throughout the Shop

The tooling community is taking advantage of new products for safer mold shops and molding facilities.