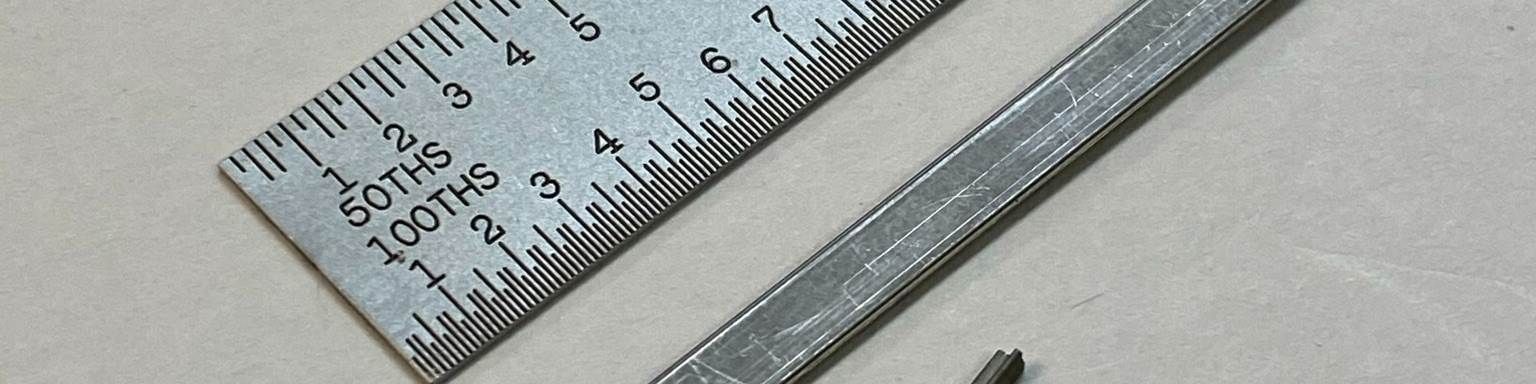

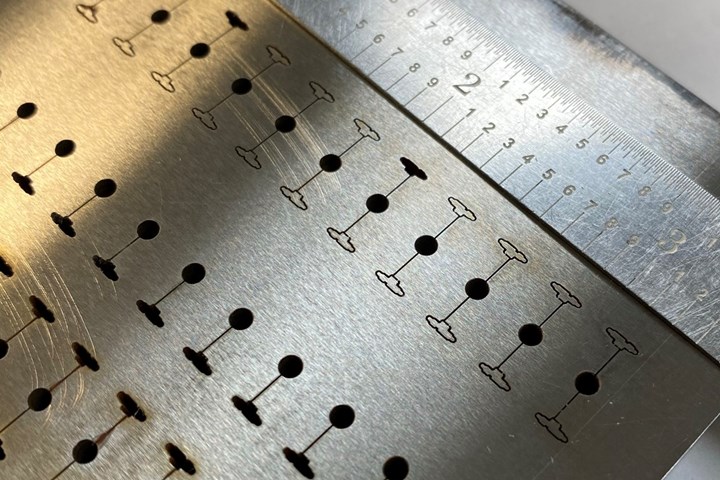

Small mold inserts punched out of wire block. Images courtesy of Ernie Green Industries.

Ernie Green Industries’ (EGI, Columbus, Ohio) tool shop had to build 63 molds in less than one year, which required extensive, high-precision wire EDM machining. EGI’s focus is precision medical molds for non-evasive surgical devices, and many of the wired inserts and wired holes are very small (0.015 inch x 0.040 inch x 0.500 inch) or have thin steel conditions of less than 0.010 inch. However, in its current state, the shop did not have the wire EDM time needed with its two GF Progressive VP2 machines.

During the quoting phase of the project, the company laid out a timeline to determine project feasibility and quickly discovered it did not have enough wire EDM hours. Average cut time was 126 hours per week (6,300 hours per year). EGI needed to find alternative solutions without investing in machines or staff.

1. Review All Processes to Determine Where Efficiency Improvements Can Be Found

Utilizing two machines, EGI had 38 hours available cut time at 80% efficiency; however, it was only achieving an average of 21 hours cut time per day, or 52% efficiency. The EGI team decided to put multiple blocks in the machine. Then it looked at how its toolmakers dropped inserts/slugs, as EGI’s are so small they could be easily lost in the tank, or if they got into the machine head, the insert could cause costly machine damage.

2. Challenge the Team to Look Outside the Norm

The initial solution was to buy two additional machines at the cost of $325 thousand per machine and hire the two to three additional staff to run the machines, but these were not viable options so the team had to improve our current efficiency rate instead.

EGI discovered it could catch each insert/slug using Autofix, an already-available function offered on our machines. Implementation of these two steps helped achieve an efficiency of 90% or more and significantly increased available capacity.

3. Collaborate With Equipment Suppliers to Maximize Existing Machines

Reaching out for support to the EDM machine manufacturer helped the EGI team discover the Autofix function and implement it within one day. Autofix goes back to each wire tab and reduces it so that the insert can be tapped out with a small punch after the block was removed from the machine. EGI also learned that it PEPS CAM system has a similar function to Autofix, which provides multiple ways to achieve efficiency for wiring small, high-precision inserts and pockets.

4. Invest In Employee Training

When identifying the placement of multiple blocks in the machine as a solution to improve efficiency, EGI realized that its toolmaker had always put one block in the machine at one time in the same spot. The toolmaker didn’t know that putting multiple blocks in the machine, which would enable us to run the machines for extended periods, including over the weekend.

EGI profitably completed the project requiring 63 high-precision molds and is considering additional wire EDM work because of open capacity.

Related Content

Machining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read MoreMaintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

Read MoreRevisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

Read MoreHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreRead Next

2020-2023 Editorial Advisory Board: Meet New Board Member James Jergens

The 2020-2023 version of MoldMaking Technology's EAB features a new crew of 12 industry professionals. Here's one of them.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More