Similar to the headache of sorting through years of emails trying to find one from a vague memory, a CAD library can become a disorganized clutter of knowledge, making it difficult to find the relevant information when needed.

Whether starting fresh or reorganizing a legacy collection, here are five priorities for building an efficient CAD library to benefit both longtime and newly joining members of a mold design team.

-

Establish a main library.

The first step is to set up the main library of components for primary selections. This library should be set up with the common and approved components easily accessible and kept to a manageable size. The fewer folders and files that must be viewed and clicked through, the faster it is to navigate. Also, a smaller library reduces the decisions needed in the early stages, which yields faster and more consistent designs.

-

Add secondary libraries.

Any sometimes-chosen features can be kept outside the main component library so that they don’t have to be sifted through on every job. In addition to folders established for seldom-used components, there would be in-house custom component preferences, as well as folders set up for OEM/Tier 1-specified mold lifting blocks, gate inserts, etc. This type of library structure reduces decisions directly relating to a faster and more consistent design. Any components on a do-not-use list should be documented and all CAD data should be deleted.

-

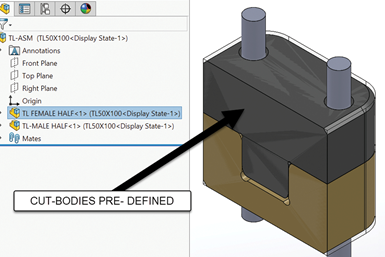

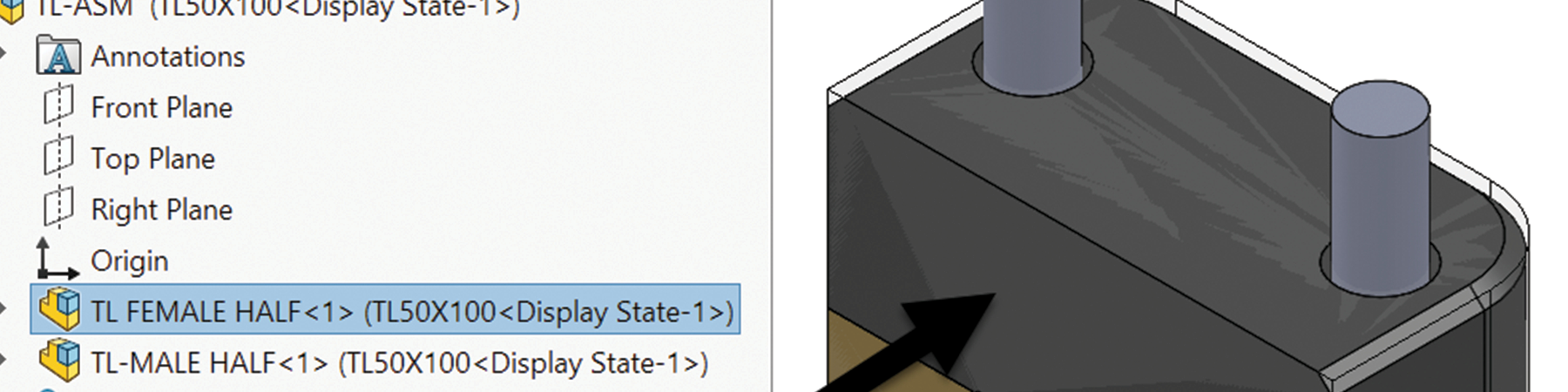

Reuse data.

Continuously improve these libraries by ensuring the team is aware of any task that is done twice when inserting a standard component. Professional CAD software provides a way to save this task for repeated use. For example, drawing component pocket geometry should only be done once and be able to be reused. This can be programmed into your software’s mold package or feature library or offered directly from the component supplier. Any manual dimension input creates an opportunity for error and having a well-built library with reusable data will reduce common mistakes and save secondary steps involved in checking.

Fully leveraging the technology when managing a CAD library allows a design team to focus on cavity and core details and spend less time on repetitive design tasks.

-

Define standards.

Control the library with a standards document defining company standards such as tolerances, orientation and colors. Define anything that will help efficiency, but be cautious so as not to over-restrict and bog down the design process.

-

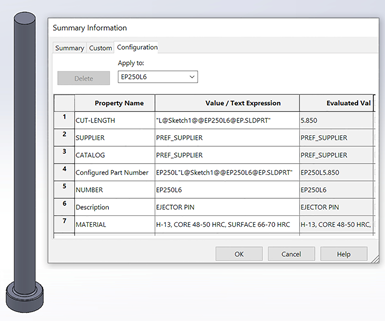

Advance BOM population.

Shown is a vendor-supplied SolidWorks library item for setting up automated BOM population.

One of the biggest opportunities to reduce manual input is to populate the bill of materials (BOM) directly from the 3D design. Time can be invested into defining what the final BOM must look like for efficiency down the line, and then each component in the library can be set up for this BOM and the necessary info can be pulled from it for ordering. Mold design activity has its ebbs and flows, and this process of BOM preparation is a great use of time in between hot projects.

A well-built and diligently maintained library is a valued repository of company standards and consistent design expectations. Fully leveraging the technology when managing a CAD library enables a design team to focus on cavity and core details and spend less time on repetitive design tasks.

Related Content

Tolerancing in Mold Design, Part 2: Using GD&T to Address Conventional Tolerancing Issues

Mold designers can achieve a single interpretation of workpiece functionality when following the American Society of Mechanical Engineers Geometric Dimensioning and Tolerancing standard.

Read MoreVIDEO: Perspective on A.I. and Mold Design

Bill Genc of TopSolid shares his perspective on the benefits of and barriers to using artificial intelligence in mold design.

Read MoreWhat is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

Read MoreIndiana Mold Builder Decatur Mold Offers a History of Grit and a Future of Innovation

Decatur Mold Tool and Engineering Inc. serves as a tooling tour guide, helping busy tooling managers reduce uncertainty, lighten workload.

Read MoreRead Next

VIDEO: Standardization and the Future of Moldmaking

Progressive Components President Glenn Starkey discusses their focus on standardization and the future of moldmaking (it’s here to stay!).

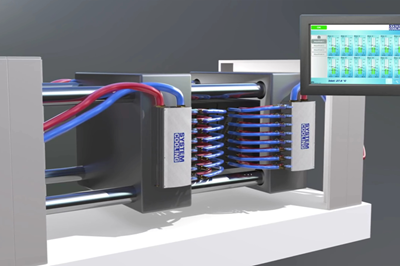

Read More5 Ways to Make Your Tooling Assets Smarter

Global mold monitoring and asset management solutions can maximize productivity and efficiency.

Read MoreVIDEO: Simplify Mold Management of Your Tooling Fleet

In this digital demo, Progressive Components explains its basic asset management and mold monitoring system, ProFile, where it is possible to monitor all your assets in one place.

Read More.jpg;maxWidth=970;quality=90)

.jpg;maxWidth=300;quality=90)