Machining

What Driven at the Center of Gravity Means To Your Machine Tool

Getting to the bottom of the technology that is built into today’s machining centers will help you select the best machine tool for your application.

Read MoreConsider The Control Before You Buy

Your machining center’s control could mean the difference between rapid productivity and costly downtime.

Read MoreEnsuring a Long Machine Tool Lifecycle

Save time, money and aggravation by taking care of your machine tools with a lifecycle approach.

Read MoreWaterjet Cutting and Where It Fits in the Mold Build Process

Waterjet features and applications mold manufacturers should consider.

Read MoreDoubling and Quadrupling Machining Speed, Capacity and Output

Vertical machining centers help to achieve the rapid tool production time a medical thermoformer’s customers demand.

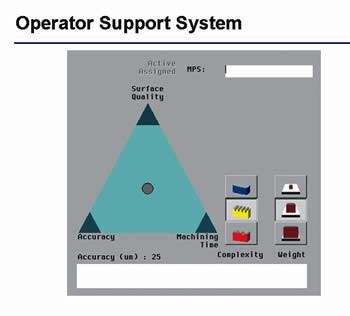

Read MoreSmart Machining: A New Development in High-Speed Machining

Improved process reliability, optimized machining performance and reliable unmanned operation are the results of smart machining implementation.

Read MoreIt’s Gut-Check Time for Tool Builders

It’s time to adapt or die as business evolution dictates development of new business and manufacturing approaches.

Read MoreExtreme Tool and Engineering: Building Relationships, Fostering Growth

This moldmaker proves that dedication to its customers combined with a will to thrive in a global marketplace is the right formula to win the MoldMaking Technology 2006 Leadtime Leader Award: Large Shop.

Read MoreMachining Molds with Negative Stock Shutoffs

Negative stock shutoff can help you make better molds in less time. Here is a clear definition and description of the process. While the concept is fairly simple, the implementation can be challenging.

Read MoreThe Keys to Successful High-Speed Machining

Moldmakers will reap all the benefits of high-speed machining with the right mix of machine tool, tooling and programming.

Read More