Consider The Control Before You Buy

Your machining center’s control could mean the difference between rapid productivity and costly downtime.

The advent of the computer has altered every industry throughout the country. People may debate whether computer proliferation has made life better or worse, more efficient or just more frustrating. Maybe it’s all of the above.

However one thing is certain, the benefit of the technology depends on how well the software was designed. Whether it’s a PC or a TV, it’s all about the software in the 21st century. CNC machining centers are no different. If the software was designed with usability as a priority, increased productivity and decreased cycle times are just a keystroke away.

Therefore, the most important consideration when you purchase your next machining center is to select one with the best control. That’s the conclusion John Carpenter came to after spending weeks researching vertical machining centers. Carpenter, shop manager of BPR/RICO Equipment (Medina, OH), found more than 20 different brands that could meet the shop’s needs in terms of working cube, HP, rapids, spindle speed, etc. He realized that the key to a successful purchase was going to be selecting the machining center that had the best “operator to control” interface. The control had to be easy to learn and easy to use, but powerful enough to handle a wide variety of machining operations.

Some CNC machining center manufacturers have a “one shop stop” approach—they integrate the control, the software of the control and the machine altogether. One company oversees the design and manufacture of the entire product—sort of a “plug and play” solution. Other companies rely on third parties to provide the control and software that works with the machining center. You buy the machine and choose your control and software.

Whether the control for your machining center is integrated or separate, the issues to consider during your pre-purchase research are the same. This article explores some of the main issues around machining center controls and software and how to get the information you need.

Ease of Use

There isn’t a company out there claiming, “Our control is so difficult to use you have to be a computer programmer to figure it out!” So how do you really know that the control is “user friendly” when they say it is? First of all, ask for a demonstration from the sales representative and make sure the people who will be using the machine are involved in the demo.

Secondly, ask the sales representative for a customer reference. Whatever your concerns or situation, ask him if he has another customer whose experience is similar to yours (e.g., manual machine to first CNC machine; similar job requirements; or switching from one brand of machine to another).

A truly easy-to-use control can mean the difference between productivity and downtime due to the frustration of figuring out the quirks of a control. Mark Lanese, of Lanese Quality Tool (Centerville, OH) says the standard conversational programming option of the control on his TM8 slant-bed lathe was so easy to learn that he was producing parts himself just one day after he got the machine.

Berry Plastics, an international plastics molder with headquarters in Evansville, IN, says a control that’s easy to learn and easy to use is imperative—especially when lean is a way of life. At Berry, one moldmaker runs at least three machines, which demands that the machines are easy to setup.

Mike Ingersoll, manager of the prototype shop at Goodrich Aerospace (Charlotte, NC), says a control that’s easy to use enables him to maximize the resources of his employees. The old NC mill at Goodrich was extremely difficult to program, according to Ingersoll, and only one member of his team knew how to do it. With the standard conversational control programming software on his vertical machining center, Ingersoll says all of his machinists have been cross-trained to use it.

Ergonomics

In addition to having software that’s easy to learn and intuitive, make sure the physical part of the control is designed ergonomically. Is it a barrage of buttons and dials or a simplistic presentation with easy-to-read button labels? Is the control angled for maximum ergonomic use or just straight up and down with no ability to adjust it?

Flexibility

The flexibility of the control has a lot to do with how easy it is to use and learn. The more programming options you have, the more flexible your business can be.

First, find out what the “standard” con-trol includes. Some companies say they have the most flexible control, but only if you spend thousands of dollars on additional software and feature upgrades. What does the standard control (software) include? NC is the minimum (G codes and M codes).

Conversational (sometimes called “shop floor”) is a big plus. Most companies offer this programming method as an additional option. If conversational programming is included as part of the standard control package, you’re getting a real bargain.

Conversational programming is the key to cross training employees and increasing your shop’s productivity. Conversational is to G-code what Windows is to DOS computer code—it’s the skin that goes over the G-code. Conversational programming asks the operator to enter information about the job through on-screen prompts. The information is sent to the machine’s software to set up the job.

Matt Schenk, lead moldmaker at Berry Plastics (Evansville, IN), says programming rotary work using conversational programming is incredibly easy compared to working with G-codes. Schenk says he saves about an hour per setup with conversational.

Mike Vella, owner of Florida Precision (Melbourne, FL), says a flexible control has allowed him to maximize the talents of his employees and increase efficiency. With the control, his employees can choose between ISNC programming or conversational.

According to Vella, his manual machinists take the DFX CAD files to the machine and are comfortable with the control and productive in just a few days. “And the G-code guys, literally in a day or two are up to speed,” says Vella. He says the time savings is significant—a part that needed 492 lines of offline generated G-Code took only 18 lines (about 8 minutes worth of work) using the control’s conversational programming method.

Other Features

Some other features to look for as part of the standard control package, and features that are extremely beneficial and/or necessary to make the control work efficiently include:

- User macros

- Rotate and scale

- Look ahead (find out the number of data blocks capable and block processing speed)

- Hard drive

- Spare ‘M’ functions

- Auto interrupt

- Tool change control (automatic/manual)

- Network connection (LAN)

Beyond what is standard, find out what software options are available and how much they cost. Make sure the sales representative tells you the benefits—the real world application. You don’t need to pay for a bunch of bells and whistles if your shop won’t benefit from ringing those bells and/or blowing those whistles (see Features with Real World Benefits below).

Computer Requirements

Although it’s a machining center, we’re dealing with computer files so the amount of memory and the type of processor

matter. Make sure you find out the numbers:

- Hard drive: Does it have one and if it does, find out the capacity/size.

- RAM (memory): Find out how many MBs (megabytes) it has standard and what the expandable MB limit is.

- Processor type: If you haven’t heard of it, do some research. The processor determines the speed of the software. It’s measured by BPS (bits per second) processing speed.

Features with Real-World Benefits

Sometimes it’s difficult to actually figure out the real-world benefit of a feature, and to compare one brand’s set of features to another because each company uses a different set of “catchy” names to differentiate its machines’ set of features. This is where your local sales representative makes a difference—a good one will cut through the mumbo jumbo and explain which features have real value for your shop and the type of jobs you do.

Below are some features that have real-world value. Make sure the bells and whistles you buy do, too.

Graphical Data Block Search

Data block search saves time and saves the frustration of searching through lines of code to find the error. The data block search feature maximizes the on-screen graphic representation of the part—simply touch the section of the picture on the screen that needs adjustment and the control automatically takes you to the line of code that corresponds to that specific portion of the part.

John Carpenter, shop manager of BPR/RICO Equipment, provided a real-world example of how graphical data block search has benefited the shop. Carpenter explains that every job was the same but different. In the design of its equipment, the basic components were similar, but each order had some element of customization—holes in a different location, different length, etc. On conventional CNCs, each change required a new program and then edits to finally get it to run. Carpenter said the automatic data block search feature on his vertical machining center’s (mill’s) control allows his guys to alter programs quickly. The operator displays the part on the screen and literally “points” (using the touch-screen) to the specific feature on the part—a hole for example—that needs to be changed. The control’s software automatically goes to the data block that corresponds to that portion of the part and edits can quickly be made.

Verification Graphics

At Bryco Machine (Tinley Park, IL), the lathe operator says he thinks a unique feature on his CNC slant-bed turning center’s control called verification graphics will eventually eliminate machine stoppages. With the verification graphics, he can see the cuts graphically on the screen before they are made. The operator at Murray Mold and Tool says this feature leaves no reason to make expensive and time consuming mistakes or “trial runs” on real stock. With both shops, the verification graphics feature was a big selling point because they could see the real world benefit—the feature saves time and money.

Program Interrupt

Sometimes the simplest idea can save tons of time and hassle. The program interrupt button on their control has given Kevin Jurus of SFR Turning (Howell, MI) complete control and comfort. Jurus explained that he can press the program interrupt button at any point, have the tool re-track, and he can inspect the part or make adjustments. When the button is pressed again, the machine resumes its program exactly where it left off. According to Jurus, other controls have to restart from the beginning of the program and waste valuable time getting “back in the cut.”

DXF Transfer

Operators that value time, value the capability of the DXF transfer feature. This software control feature allows DXF (Data eXchange Format) files to be downloaded directly from the CAD image to the machining center’s control. Die Tron, Inc., in Grand Rapids, MI, reports that using DXF transfer (sending the CAD drawings direct to the machine for programming) saves 20-30 percent over offline and downloading.

In addition to eliminating the need to enter the data for each hole location or milling profile at the CAD station, DXF transfer eliminates data entry mistakes because the tool-paths are created directly from the part geometry of the CAD-generated DXF file.

Prepare for the Future

As with any software, engineers are continually improving it and tweaking the code. Therefore, it’s important to ask about software upgrades for your control and whether you will receive them at no cost for a period of time. Additionally, find out if downloads of software “patches” are guaranteed as part of the purchase.

You probably don’t expect a company to give you upgraded software forever, but you want to make sure they take care of you fairly to make sure the software isn’t obsolete a month after you buy the machine.

Training and Tech Support

Ask about training classes—where, when, how large is the class size, what the qualifications of the instructor are, and how much it costs. Also, find out about a technical support line—most have one available, but you want to know the hours of operation and what to do for after-hours support. Also, ask if their tech support is offered via the Internet and/or e-mail in addition to the phone.

Summary

As John Carpenter of BPR/RICO realized after much research, the differentiating factor when you’re purchasing new equipment for your shop will be the machine’s control. For most people, the control is more difficult to evaluate because the software part of how it works is hidden compared to the other features of shop equipment, such as the size of the table, footprint, etc.

To buy a machine with the best control, make sure the features have real benefit to you and the type of work your shop does, request a demonstration, take the time for employees to evaluate the control, and make sure the company in charge of making the control and its software has a history of stability—you want to ensure they’ll be around for a long while to support their product.

Related Content

How to Generate the Ideal Tool Path for High-Level Accuracy and Finish

When a mold builder can’t compromise part accuracy and surface finish, CAM software with specialized programming strategies is essential.

Read MoreHow to Analyze and Optimize Cutting Conditions to Reduce Cycle Time

Plastic injection mold design and manufacturing company puts NC program optimization software module to the test. The results were surprising.

Read MoreThree Good Reasons to Switch from Three- to Five-Axis Machining in Moldmaking

Five-axis machining technology is a great tool in the moldmaker toolbox.

Read MoreMold Innovations Power Unique Auto Lighting Elements on Hummer EVs

Diamond machining, electroforming of micro-optical inserts and modified latch-lock system help injection molds produce unique forward lighting elements.

Read MoreRead Next

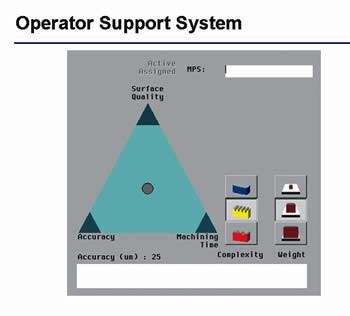

Smart Machining: A New Development in High-Speed Machining

Improved process reliability, optimized machining performance and reliable unmanned operation are the results of smart machining implementation.

Read MoreTaking Control of Finer Surface Finishes at Higher Speeds

An increased interest in five-axis machining—coupled with advances in controls and cutting tools—add up to finer surface finishes at higher speeds.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More