Machining

Shrink Fit: The High Accuracy Toolholder of Choice

Requirements in the mold industry are much more precise than general machining, so more attention must be paid toward the selection of the appropriate toolholder in regards to its features and benefits.

Read MoreA Machine Cuts Carbon and Hard Steel at 60 Percent of the Cost

The right high-speed machining center and software helps one mold builder turn an important corner in mold building productivity.

Read MoreComplex Parts Put a Premium on High-Tech Mold Design

Equipment and component suppliers are developing a range of products for advanced moldmaking needs.

Read MoreSelecting an Economical VMC for Mold Machining

The key to investing in the right vertical machining center is in sizing up your current process requirements and machining capabilities, while factoring in future work.

Read MoreSelecting the Best Toolholding Solution for Your Shop

A look at ER collet systems and a review of the properties to look for when making your toolholding purchase decision.

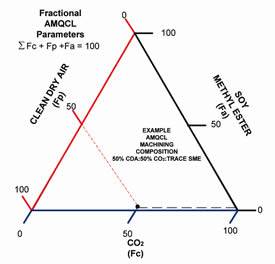

Read MoreMachining with Advanced CO2 Machining Spray Technology

Advanced CO2 machining spray technology delivers robust, high performance and adaptive cooling and lubrication for challenging mold machining applications.

Read MoreFive-Axis Machining: What Are The Benefits and How Can You Achieve this Capability?

The alternative you choose to achieve five-axis machining benefits will be application driven and can have a significant effect on your bottom line.

Read MoreAccessorize Your Machine to Maximize Performance and Efficiency

Machine tool accessories offer economical solutions to many of the production and timing issues that can negatively impact tool and machine setup.

Read MoreMilling Molds Right the First Time

Proper end mill selection is critical for one manufacturer of high-end, one-off custom molds.

Read MoreUsing High-Feed Machining Strategies to Get to Net Shape

High-feed tooling and high-feed machining could be the key factor in maximizing your shop’s roughing efficiency.

Read More