What Driven at the Center of Gravity Means To Your Machine Tool

Getting to the bottom of the technology that is built into today’s machining centers will help you select the best machine tool for your application.

When new technology emerges in today’s rapidly changing market, it is vitally important to look past the buzzwords and focus on the real life results it can have on your bottom line. Driven at the center of gravity technology is one such technology that moldmakers should look into before purchasing their next machine tool.

Underlying Technology

Many moldmakers have likely heard of driven at the center of gravity technology and understand that it enables superior surface finish textures and extended tool life, but to fully comprehend the benefits, one must understand the underlying technology.

An object’s center of gravity can be defined as the average center of its mass. This also is the object’s balance point. During movement, application of force at a point other than the center of gravity will cause strain and a tendency to rotate. This basic principle is very simple to demonstrate and understand. When a pencil is placed on a level surface and pushed at its center, it will roll forward. On the other hand, if pushed at just one end, the pencil will tend to rotate. While the forces opposing the pencil’s movement are uniformly distributed, the force causing movement is being applied unevenly.

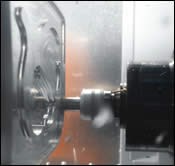

While a very basic idea at its core, the center of gravity is typically ignored in traditional machine design. A machining center axis is typically defined by a pair of linear guides and driving mechanism, usually a ballscrew and servo motor combination. With a proper understanding of center of gravity, common sense would dictate placing the ballscrew in the center of the axis. This would balance the driving force and avoid twisting the axis during movement. Unfortunately, this ideal scenario is often impossible to achieve within a machine tool.

Obviously, a single ballscrew drive cannot be placed in the center of an axis when another machine component must occupy that space. In many machine designs, a fourth axis table or tool spindle is located in the center of an axis. Traditionally, machine tool builders have compromised and mounted the ballscrew on the left or right side of the center of gravity, creating an unbalanced loading of the driven components. While this was not a significant detractor to overall quality levels in the past, it has become an Achilles heel to the potential for high performance afforded by other breakthroughs in machine design.

All materials, even metals, possess a degree of elasticity, causing them to deflect when subjected to stress. In the context of machine tool design, the greater the force generated by an imbalanced drive, the greater the deflection. This causes a dramatic effect in regards to vibration of the tool tip, as the metal between the driving point and the tool tip deflects, causing both inaccuracy and reduced quality of finish.

Machine Tool Design

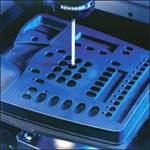

Driven at the center of gravity technology works to reduce vibration and its negative effects by driving movement through a simulated center of gravity. By implementing twin ballscrews equidistant from the actual center of gravity, driven at the center of gravity effectively eliminates deflection as the machine moves along its axes. In terms of the previously mentioned analogy, it would be the equivalent of applying equal pushing force at both ends of the pencil, causing it to move uniformly.

Advantages

The application of driven at the center of gravity technology provides multiple benefits to today’s moldmaker. Efficiency is improved through increased speed, as machine components can accelerate much faster without imparting vibration to the tool tip.

Additionally, the much superior surface textures achieved through driven at the center of gravity technology result in dramatic reduction, if not outright elimination, of hand finishing/polishing operations. This results in significant savings, both in time and cost. In fact, the elimination of this bench work can be the single most critical factor in keeping mold work in the U.S. Obviously, components that require many hours of hand polishing are very sensitive to the cost of labor. When driven at the center of gravity eliminates this labor-intensive process, domestic moldmakers no longer suffer a disadvantage relative to those regions with lower labor costs.

Reducing vibration also improves tool life. This provides significant value when cutting large cavities in which it is difficult to complete the cut with a single tool. When a tool requires replacement during a machining process, the component being produced often exhibits blemishes that must later be removed. Thus, enabling the cutting of large cavities with a single tool serves to further reduce or eliminate polishing time.

Benefiting from What Lies Beneath

When new technology becomes available, manufacturers need to look past the buzzwords to find where the true benefits lie. With driven at the center of gravity technology, a revolutionary new approach to machine design has provided dramatic reductions in machine vibration. Through driven at the center of gravity, today’s moldmaker stands to achieve increased quality while saving the time and money required to be competitive in a global market.

Related Content

Machining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read MoreSolving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

Read MoreRevisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

Read MoreAdvantages and Disadvantages of Copper and Graphite Electrodes

Both copper and graphite provide approximately the same end result, so it is important for a shop to consider the advantages and disadvantages of each material in order to discover what would work best in their shop floor environment.

Read MoreRead Next

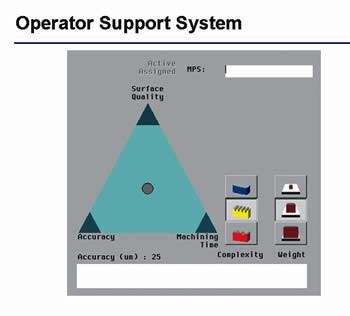

Smart Machining: A New Development in High-Speed Machining

Improved process reliability, optimized machining performance and reliable unmanned operation are the results of smart machining implementation.

Read MoreHow to Select and Use Your Vertical Machining Center

Competitive shops need to consider the true capabilities of their VMCs to achieve a high level of accuracy and surface finish.

Read MoreThe Argument for Horizontal Machining Centers

Although VMCs are widely used, HMCs offer more flexibility, versatility and a number of operations in one machine tool.

Read More

.jpg;maxWidth=300;quality=90)