Waterjet Cutting and Where It Fits in the Mold Build Process

Waterjet features and applications mold manufacturers should consider.

We see it all around us every day. Manufacturing in the U.S. takes a beating with fingers pointing in all directions. Theories abound as to why it’s getting tougher to survive in business. Just recently, large domestic automobile manufacturers announced the elimination of 60,000 jobs in order to heal the bleeding and realign themselves with competition. To cap it all, finding good co-workers and employees who are committed and dedicated to a vision of growth and expansion, as opposed to having a job and coming to work, seem out of reach. So what is the answer and where do we turn?

The end users who demand lower prices, higher tolerances and quicker delivery on parts are the ones driving the forces of change. Not everyone is closing down. In fact, the opposite is occurring for some. Certain companies seem to be thriving as they grow, providing products and services while competitors grind to a halt. While some airlines are reporting profits and ordering more than 500 new jets, others are cutting back, laying off, grounding jets at airfields in the desert and reducing flights. But all airlines serve the same customers.

Logic says established businesses that have paid off their buildings and machines and have a workforce where the average employee has 10 to 20 years of service under their belt, are stable, strong and posses all the infrastructure to continue growing. Apparently not! It often seems the companies with everything going for them have become stagnant, complacent and fall the hardest.

We are no longer in a world where the traditional wins, where five-year projection plans survive and we all go home at night feeling secure in our future. Survival has become dependent on sideways thinking, a relentless pursuit of new ideas and creating a culture where people—from the shop floor to the receptionist—know that their input counts and is valued. Where freedom of thoughts, concepts, ideas, modifications, upgrades and processes are all focused on the ever-changing target ahead.

Waterjet: A Piece of the Survival Puzzle

And what on earth does all this have to do with waterjet cutting and moldmaking? Well, everything really. Waterjet may be one of the pieces of the puzzle that could allow your company to leap forward with minimal cost and gain huge returns. Waterjet might double the output of a shop without employing more people or buying any additional machinery, other than the waterjet. Waterjet could be something that allows your business to provide more product at a lower cost. Waterjet could be the one piece of equipment that turns your mold shop around and opens up the doors to increased production, efficiency and better utilization of existing equipment.

Where waterjets cannot hold tolerances to tenths of a thousand of an inch in 10-inch stainless steel or six-inch A2 tool steel, they do cut all the way through, pierce their own holes, and can certainly be used to get within acceptable tolerances for clearance holes and near-net-shape cutting.

Waterjets eliminate hours of hogging out material producing low value chips, and replace it with clean, through cuts with valuable drops that can be used for other projects. Waterjets can achieve tolerances up to +/- 0.005” on many materials thinner than say two inches, but the moldmaking industry typically works with thicker, heavier materials where it would not be wise to count on such tolerances.

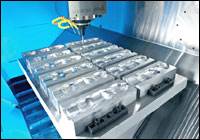

Using a waterjet to do all preliminary cuts on a die or mold and get it to a point where only the final machining is required, frees up the high cost, high tolerance mill to be used for the purpose it was purchased and built—specifically the final high tolerance finishing of parts.

The combination of capabilities of a waterjet and mill could allow a dramatic increase in output and hence revenue. The same staff running the mills could be used to run the waterjet, and the same programmer can easily do all programming. It could be that the waterjet could prepare two to three molds ready for machining in the time it takes for the CNC mill to do the final machining of the part. If the mill time is simultaneously reduced substantially, and is used primarily for milling the finished tolerances, each mill could possibly increase its throughput several times.

A waterjet also can be a great tool for modifying molds and dies at a reduced cost. With the increased cost of materials, everyone is looking for ways to cut costs, and one is to reuse or modify an older die or mold.

Evaluating Waterjets

However, not all waterjets are created equal, and just as some manufacturers may be in danger of falling behind the car manufacturers and airlines, others are surging ahead with innovative options that are setting the pace for others to follow. A careful evaluation of the philosophy of the waterjet manufacturer is critical. You don’t want to be left with a machine that you should be happy with because the last 100 customers have not complained. Purchasing a machine that will grow, expand and has been configured to meet all sorts of new options—some of which may not even be in existence yet—is important.

So let’s look at some of the innovative ideas that are on the horizon for waterjet that you need to be sure you are not about to miss out on.

Plate Alignment, Part and Program Rotation and Indexing

A waterjet—when mounted onto a system that allows options like plate alignment, part and program rotation, along with the ability to index the waterjet stream to within 0.001"—is a powerful tool. Not all waterjet systems have these features and instead force the operator to line the part up in the X or Y axis and then using an indicator to check alignment, limiting the ease of use of the waterjet.

Laser Pointers, Laser Projection and CCD Video Camera Sensing

Being able to use a laser or CCD video camera mounted onto the cutting head to sense or locate points on the part to be cut could be real time savers. Using lasers to indicate a start point is relatively old technology, but using a CCD video camera to trace the shape of a part, in effect acting as a large digitizer the size of the waterjet cutting table, is not commonly found on waterjets. To take things one step further, it is now possible to have the actual shape and toolpath projected onto the parts to be cut by mounting a laser above the waterjet.

It is believed that waterjet cutting is only beginning its debut, with unlimited possibilities on the horizon, and it looks like the prices of waterjets will be coming down in the future, making it possible for smaller shops to be able to access the technology. This is evident in some of the new waterjet systems out there. For example, one system makes it possible to place a small self-contained waterjet cutting tank on the bed of any CNC mill and within minutes use it as a waterjet cutting system. Then, when the waterjet cutting is complete, the mill can be used again for its original purpose.

Milling with Waterjet

The term waterjet machining is being used more nowadays as opposed to waterjet cutting. Along with this is the soon-to-be-used term waterjet milling. This has been demonstrated over the years and used in specific applications under controlled environments, but has not really been financially viable to date in a job shop environment. It is expected that milling will be released as an option on some machines this year, making machining of tough to work with materials a piece of cake.

Height sensors, programmable Z axis, remote access to controllers enabling diagnostics and upgrades of software, advanced abrasive delivery systems, monitored abrasive flow, pressure, cutting speeds, taper compensation for increased cutting speeds under certain circumstances, multiple head cutting, wireless hand-held pendants, feedback and monitoring of cut times, cut progress and interactive communication with operators, are but a few of the options that could make waterjet cutting something your shop needs to consider.

Related Content

Tips for Tackling Mold Design, Machining, Cutting Tool and Wear Challenges

Tips for tasks ranging from reducing risk in part design and taking advantage of five-axis machining to refining cutting tool performance and reducing wear with guiding and centering systems.

Read MoreSolving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

Read MoreDevelopments in High-Speed Machining Technology

There have been many exciting developments in high-speed machining relative to machining centers and controls, tooling and CAD/CAM systems.

Read MoreRead Next

Looking Sharp

Advancements in cutting tool/toolholder construction yield better stability and higher accuracy to achieve greater feedrates and increased productivity.

Read MoreTaking Control of Finer Surface Finishes at Higher Speeds

An increased interest in five-axis machining—coupled with advances in controls and cutting tools—add up to finer surface finishes at higher speeds.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More

.jpg;maxWidth=300;quality=90)