FAQ

Make a Case for Your Favorite Product in MMT

Like Sherlock Holmes, I’m looking for clues. The right clues will lead me to uncovering the facts about products that have significantly impacted the operations of moldmakers and molders. So readers, consider this a call for case studies!

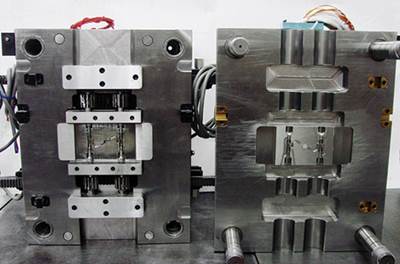

Read MoreProcess Cooling Boosts Mold Efficiency

Mold builders can optimize mold performance by taking advantage of advanced process cooling technology.

Read MoreUnder the Scope: Understanding the Task

Asking a few simple questions will help the welder prepare for the job at hand to turn it around as quickly and efficiently as possible.

Read MoreA Common Foundation for Speedy Mold Builds

Exacting, interchangeable base plates help this shop start projects quickly and without distractions.

Read MoreLooking for a Tool Steel Heat Treatment Source?

How does agitating a quench liquid improve quenching speed? Why do tool steels require a high austenization temperature for hardending? How thick can a P20 mold steel be through hardened into the center? These and other questions were answered during last week's webinar on heat treatment basics.

Read MoreDo You Want to Know Why Plastic Parts Warp?

I have worked with Tim Lankisch, director of engineering at CAE Services on numerous technical articles and educational videos in MMT focused on the value of simulation. Yesterday Tim came off the printed page and went live in an MMT webinar that analyzed why plastic parts warp. View archived recording now.

Read MoreLaser-Focused on Lean

This toolroom made significant strides in reducing waste and improving workflow with the addition of just one piece of equipment: a mobile, flexible laser welding system.

Read MoreMaking Wear Predictable

With thorough documentation and an investigative mindset, preventive maintenance becomes an uptime-boosting feedback loop of continuous improvement.

Read MoreTax Benefits from Manufacturing in the U.S.

The IRS has issued recent guidance related to the domestic production activities deduction (DPAD) that may be particularly favorable to moldmakers.

Read MoreCryogenic Basics

Cryogenic machining technology milling fluid end component made of 4340 high alloy hardened steel.

Watch