FAQ

Tradeshow Tuesday: Twitter on the Tradeshow Floor, Part 2

This week in Part 2, I cover Twitter basics so you can leverage this social media platform as a communications and marketing tool on the tradeshow floor.

Read MoreTradeshow Tuesday: Twitter on the Tradeshow Floor, Part 1

Twitter is a useful trade show tool for attendees and exhibitors alike. In Part 1, I make the case for using it, and in Part 2, I’ll get you started with Twitter basics to help you feel confident about using Twitter on the tradeshow floor.

Read MoreEssentials of Machine and Process Protection for Moldmakers

A modest investment in machine and process monitoring technology can help alleviate the expensive or catastrophic consequences of human and equipment limitations.

Read MoreThrowback Thursday: How to Prevent Hot Runner Leaks

One of the more common concerns still expressed by molders today about hot runner molds is the threat of a leak of molten plastic causing the manifold pocket to fill. Here is a throwback to an article on leak prevention focused on externally heated hot runner systems.

Read MoreApprentice Training: Related Technical Instruction

Ryan Pohl presents a review of important classes for Related Technical Instruction (RTI) that will establish a robust apprenticeship program.

Read MoreHow to Proactively Engage Educators with Plastics

RJG Inc. participates in Tuesdays for Teachers initiative to further engage educators with plastics industry career opportunities and STEM teaching resources.

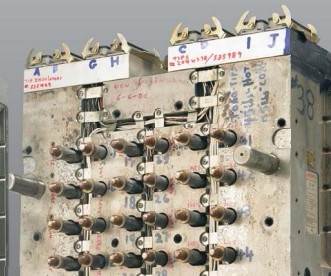

Read MoreTake a Look Inside Deep Hole Drilling

Do I have your attention with this shot? It’s the inside of a gun barrel. What does that have to do with moldmaking? More than you think when it comes to deep hole drilling your waterlines, cross hole drilling, and deep pockets at compound angles, and on one machine instead of three—boring, five-axis machining and deep hole drilling in one accurate yet approachable machine.

Read MoreApprentice Training: Metallurgy

Metallurgy for mold materials for tool and die apprentices should cover mining, furnaces, properties, testing, alloying, processing, classification and heat treatment.

Read MoreThrowback Thursday: Criteria for Effective EDM

The work metal, EDM process priority, electrode material and machine are the four main considerations for effective EDM of non-standard alloys. These four areas play a critical role in making the overall EDM process profitable. Read this archived article for more.

Read MoreThe Bottom Line: New Rules for S Corporations Offer Flexibility with Profit Taxes

The Protecting Americans from Tax Hikes Act (PATH Act) permanently shortened the S Corporation “built-in gain holding period,” making it more attractive for corporations to elect status as an S Corporation and the treatment that such a status incurs. This gives mold shops more flexibility as to how they are taxed on their profits and the eventual sale or transition of their businesses.

Read More