Design Capabilities and a Lean, Skilled Team Makes Do-Rite Die & Engineering a Valuable Source for Die Cast Dies

Do-Rite Die & Engineering’s skilled team knows how to achieve creating even the most complex details using EDM or a combination of electrodes and three-axis machining.

Share

What do you believe sets your company apart from other shops?

Paul Szymanski, vice president: For one, the fact that we are pretty much 100 percent die cast dies. We do some repair work on molds for plastic, but very little. I believe that is rather unique for a shop to be primarily building die cast dies, and we have a lot of expertise in that area.

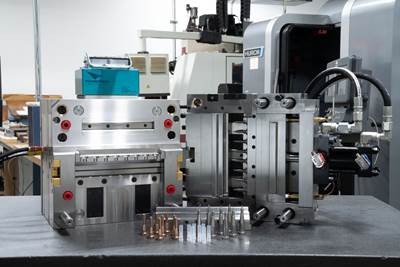

One of our biggest advantages is that we have in-house design capabilities. We design die cast dies and can perform repairs and make modifications quickly for customers. This service extends beyond the dies we designed, too, of course. We have no problem drawing up any design details that need refurbishment or modification. Many of our larger customers may have in-house design teams, but we also work with smaller businesses that do not and so this service is an advantage for them especially. We can also assist with part design, providing solutions for how to improve gating, reduce porosity or for making it easier to eject the part. Oftentimes, we are involved in fine tuning the part to make it simpler or more efficient to cast.

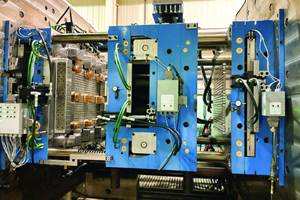

We have a small but highly skilled team, and we do almost everything in house. Typically, we outsource the die set or mold base, but all the cavities and inserts are made in our own shop. Also, all sampling and post processing is performed by our customer. This is kind of unique to die casting versus plastic molding. It is rare that a die cast tool maker would also do all the qualification work, unless they were also performing production work because of the need for a furnace. While plastic melts at very low temperatures and the molding process can be fairly clean, die casting can be very hot and messy. It requires a special, separate room or facility, and multiple safety precautions must be taken, not to mention training, clothing and other equipment. It is a whole different animal.

What are some primary differences in the way die cast dies and injection molds for plastic function?

Szymanski: Well, the concepts of both are similar, but there are different factors we need to consider for heat. Die cast dies endure a lot more heat than plastic molds (aluminum melts at 1200°F, though the tool itself may only heat to 400-500°F), so our cavities require more shutoff steel and our gating is more voluminous; water for cooling is sometimes less important because some customers would rather run hotter for better fill conditions and surface quality. Also, die casting can be a much more destructive process when it comes to the tool itself. Die cast dies, which are generally built using H13 tool steel, must be a bit more robust because aluminum requires higher injection pressures and more shutoff to prevent the tool from splitting. Because inlet velocities are so high, careful attention must be paid to placement of gates to avoid standing material. The aluminum has an affinity for steel and at these elevated temperatures causes soldering of the aluminum to the tool steel resulting in difficulties with ejection. Heat-checking can also occur due to thermal fatiguing of the tool steel during the die casting process. This degrades the surface finish of the casting and can even cause critical areas to be out of dimensional tolerance. Areas near the gate are also susceptible to erosion and washout. These factors require careful consideration when determining the flow direction and approach angles of the gating and runner systems as well as sizing appropriately to generate the required flow volume and velocity. Also, die casting requires more draft on the parts to aid in ejection.

Die cast dies generally produce between 100,000 – 200,000 shots. An injection mold might be capable of generating over a million shots. In both die casting and plastic molding, the life of a tool depends on part geometry and how the casting is gated and vented.

At this point, we have not purchased a five-axis machining center. We can machine electrodes to create complex cavity details that might otherwise require a five-axis machine to cut directly into the steel. We can use a combination of three-axis machining and electrodes to create all the details in the cavities. We use our wire EDM to ensure accurate hole sizing as well. We do plan to add five-axis capabilities at some point in the future.

With regard to tolerances, some are very critical for die casting and can require ±0.002 inch. Typically, though, general tolerances we see specified are closer to ±0.005 inch.

Let’s talk venting. How is it addressed in die cast dies?

Szymanski: As with plastic injection molds, we use venting to get air out of the die so that we have as little porosity as possible in the die casting. Where vents in plastic molds are typically very small, in die casting they are usually larger, such that they will fill with material. When designing die cast dies, we try to determine the last area within the cavity that will fill and use overflows to help eliminate voids or poor fill areas. Overflows are pockets outside of the casting area where excess metal can flow. They allow excess material to flow through harder to fill areas of the casting while keeping the tool hot enough so that the impression can be fully filled before the material begins to cool and solidify. In plastic molding, molders usually like to have a hard shutoff between the mold halves to prevent flash, but in die casting, we will sometimes allow for some flash to help with flow and reduce the possibility of damaging shutoff areas. This is less of a concern because most flash will be removed with a trim die.

Overflows might be located opposite the gate side or around the outside of the part cavity. Ideally, they are used wherever you might have a hard time filling die details, such as intricate corners.

When the part comes out of the die, it is placed into a trim die (another tool built specifically for each die cast die) that removes all the overflows and the gates, as well as punching out any flash in areas that are cast through. Those trimmed overflows and gates can go into re-melt so the material can be reused. While minimizing the amount of material per casting can be beneficial, it is less of a concern because of its ability to be re-melted and used again.

Related Content

High-Technology, Diversified Mold Builder Has Its Eye on Improvement

Commitment, engineering expertise, flexibility, quality and customer service help Wisconsin moldmaker Triangle Tool LLC discover ways to grow and build molds faster.

Read MorePartnerships Fuel Moldmaker’s Growth in Technology and Training

Family-owned precision moldmaker, now backed by Heico Companies, combines financial strength with precision expertise in thermoset and thermoplastic manufacturing, apprentice training, advanced automation and comprehensive services.

Read MoreInternational Partnership Improves IBM Preform Precision

Hammonton Mold Co. and ADOP France team up to bring injection blow mold preform design and service to the next level.

Read MoreInnovation, Diversification and Integration Guide Mold Builder Growth

Quality Tool and Die team discusses the journey from a small automotive tool shop to a diversified full-service moldmaking and plastic production facility.

Read MoreRead Next

Experience, Knowledge Base, and Creativity Give Tri-Par An Edge in Molds for High-Flow Material Parts

Expertise in building molds for parts made from highly-engineered materials and automation for molding gives Tri-Par Die and Mold Corp. key mechanisms for growth.

Read MoreIngenuity Solves Challenges for B A Die Mold Customers

MMT interviews B A Die Mold Inc. to learn how its innovative problem solving and patented PERC System for molding threaded parts has benefited customers.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More