Legacy Precision Molds Aims for Ingenuity in Every Job

This Michigan moldmaker strives to deliver quality molds through ingenuity, "nimbleness" and a dose of home-grown integrity.

Tyler VanRee, vice president at Legacy Precision Molds Inc., is a second-generation moldmaker who is not inclined to back down from a challenging mold project. His goal is to lead his team to deliver quality molds through ingenuity, “nimbleness” and a dose of home-grown integrity.

Integrity is a quality Tyler says his father, Thomas, founder and president, set a precedent for when he launched the Grand Rapids, Michigan, company in 1995. It began when Tom decided to strike out on his own after working at another Grand Rapids mold builder, Classic Die, for 12 years. He told his boss he was leaving to blaze new trails, not to chase Classic Die’s existing customers. He kept his word, all the while imparting the importance of such integrity to Tyler and Tyler’s younger brother Seth, who also works at Legacy, as well as ingraining it into his shop’s culture.

For customers, integrity is one of Legacy’s principle selling points, and their appreciation of Legacy’s veracity is well-expressed in feedback the company says it has received. In fact, Tyler VanRee says one customer told him Legacy’s integrity both during and after completing a job exceeded that customer’s expectations.

“When we sign up for a job, we make a promise to the customer to build it right, or we’re going to fix it, free of charge,” VanRee asserts. “We’re not about to just come up with a quick fix and cover something up.” He says this stands true even after a mold has been in the customer’s possession for some time after it was built.

To further illustrate this drive to “build it right,” he says his team has been working diligently to machine molds to zero so that there is very little, if any, handwork and spotting required on shutoff surfaces. He says the shop recently built a small mold for a customer with tight timing requirements. Just two days before the scheduled ship date, when the team was spotting the mold, questions about the appearance of the shutoffs raised concerns about whether the part could be molded without flash. “Because we weren’t 100-percent sure, and we didn’t want to weld on the brand new inserts, we decided to make another new insert to eliminate the questionable shutoff areas,” he says. “It was painful to do, but it was the right thing to do for our customer.”

A Nimble Approach

Ingenuity and a willingness to take on jobs others pass up is another hallmark of Legacy’s success. It starts with remaining “nimble” in its approach to a project, VanRee says, and he believes nimbleness either exists in a company’s culture or it doesn’t. “If everything is always the same, day in and day out, it becomes difficult to reprogram our brains to accommodate or execute an out-of-the-ordinary request,” he says. “Our team is accustomed to being challenged; we know how to think outside the box. For us, nimbleness means being able to field the unexpected, comprehend it and react quickly to whatever the customer needs. It requires clear internal communications throughout the project so that everyone understands the ‘why’ behind the request.”

For example, Legacy was recently awarded a multi-mold project from an automotive customer for which it quoted delivery at 14 weeks. After the mold design process was already underway, the customer then requested faster delivery, and Legacy committed to 12 weeks after it came up with new mold design options that would shave the time off of production while still meeting the customer’s requirements. In the end, VanRee says 50 percent of that project shipped even earlier, at 10 weeks.

“In this case, our ability to be nimble allowed us to more than accommodate the customer by going back and revisiting the mold design, including the manufacturability of the part, and eliminating some of the complexities that were originally designed into the tool,” he explains. Specifically, a lot of time savings was gained by being able to re-draw certain features of

the part so that Legacy could machine them in the CNC machine, versus cutting electrodes and burning those details. Bench time also was reduced, as the mills are capable of achieving smooth surface finishes more quickly than EDM operations can provide.

Ingenuity Accelerated

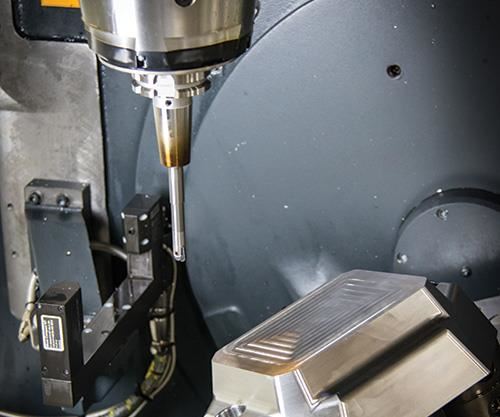

With ingenuity comes the desire to invest in better, faster machine tools and equipment that will further accelerate a company’s ability to offer innovative new approaches to mold building. Within the last two years, the addition of a DMG DMU 50 high-speed machining center from DMG MORI, with its 16-by-16-inch travel and ability to perform five-axis/five-sided simultaneous machining, has added to Legacy’s capacity to more quickly and more easily machine smaller, more complex mold components, mold cavity inserts and other items that typically require complex setups.

Namely, VanRee says the DMG has helped to eliminate certain secondary processes, like EDM, because it can access more areas of the part during cutting. This was not possible with the company’s former setup using a traditional three-axis CNC machine. Five-axis machining has also given Legacy more flexibility to design parts of the mold at angles and locations that were previously too difficult. It has also given way to more creative workholding, he says, which has added value and simplicity to both the CNC and EDM operations, not to mention affording a convenient way to secure complex mold components during manual machining operations. Legacy uses FCS-brand workholding systems and has created several custom solutions used primarily in the five-axis machine to eliminate extra steps like squaring off workpieces prior to machining. The workholding enables the shop to start with raw stock and go right into machining the workpiece.

Another recent purchase was a robot that was added to an existing electrode milling work cell to increase productivity. Almost immediately, utilization of that machine more than doubled, VanRee says, jumping from an average of 250 to 300 hours per month to 600 hours a month before finally settling in at 550 hours, including lights-out operations.

Late last year, Legacy purchased a new wire FANUC C600 RoboCut EDM, replacing two older machines that were not keeping up with the workload and causing a lot of EDM work being farmed out. Designed for greater cutting accuracy and better surface finishes, the new machine exceeds the capacity of both older machines combined, VanRee says. One reason for this is the increase in the sizes of workpiece that the new EDM can accommodate. The old equipment could only handle workpieces as large as about 23 by 14 by 6.0 inches and was limited to cutting tapers ranging to five degrees and using wire diameters no smaller than 0.010 inches.

“With the new FANUC, our max workpiece size is now 44 by 32 by 12 inches, and our wire diameters go as small as 0.006 inches, which gives us the capability to cut smaller, fussier details if required,” VanRee says. “Our angle cutting capability has increased from five degrees on the old machines to 30 degrees on the FANUC.”

More user-friendly controls, including a 15.1-inch LCD touchscreen, help lessen programming and setup times, cutting them by as much as half, he says, plus there are more options for selecting cutting technology and multiple ways to accurately pick up a part. Even when Legacy doesn’t need to cut parts as large as those that the FANUC is capable of cutting, the company still maximizes runtime, including unattended machining, by programming the machine to run multiple smaller jobs. An auto-threader keeps the machine productive even when threading soft wire while submerged and in the cutting gap, VanRee says, something the old machines were incapable of doing.

For Tyler VanRee, there’s a desire to continually improve on a good thing by investing in the business and the people, and to carry on the legacy his father set forth 21 years ago. “In retrospect, the road traveled has indeed been blessed,” he says.

Related Content

Machining Center Spindles: What You Need to Know

Why and how to research spindle technology before purchasing a machining center.

Read MoreLaser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read MoreMoldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

Read MoreThe Ins and Outs of Hot Runner Temperature Control

A training checklist that explains the why and how of proper hot runner temperature control and system management.

Read MoreRead Next

JMMS Sees Growth with Focused Program Management

Dedicated project managers present the company as a dedicated partner, not just a supplier.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More