3S for EDM

Applying the sort, set and standardize principles of 5S to EDM operations can increase efficiency by minimizing waste.

Most mold builders are familiar with the 5S workplace organization method for lean manufacturing, which embraces the concepts of sort, set in order, shine, standardize and sustain. Each aspect focuses on avoiding waste and can easily serve as a basis for continuous improvement within mold shops that use EDM and graphite. The sort, set and standardize principles of 5S can help guide EDM operations toward efficiency, minimizing waste and associated costs. This is critical in most mold shops, as EDM is often the bottleneck to reducing mold delivery times.

Sort. This 5S principle involves evaluating necessary items with regard to cost, preventing accumulation of unnecessary items, removing any unnecessary items with proper storage or disposal, and segregating and identifying materials.

It is not unusual for mold shop managers to request that employees increase productivity by better utilizing their current assets. This often creates the need to review internal processing, including how graphite is purchased and processed. Graphite is typically ordered based on specific size requirements of a new mold or in larger blocks that will be cut into pieces for the repair of existing molds. Sorting requires establishing rules for the storage and disposal of blanks, remnants and spent (consumed) electrodes. These rules might include, for example, dating and labeling all new electrodes with a job and electrode number. Sorting also requires establishing a pre-determined value for remnant storage and disposal based on the typical electrode sizes used within an operation. These values may vary greatly depending on the mold types produced.

Pre-determined values allow the operator to immediately decide where unused graphite should be stored. Shelved remnants should be stored by size for future use (see Figure 1),

while pieces not used within 24 months are candidates for disposal. Spent electrodes (see Figure 2) should also be marked by the EDM operator immediately after use as “store,” “rework” or “discard,” and then placed in the appropriate area. These rules prevent operator indecision and reduce buildup of graphite inventory that may have little or no value.

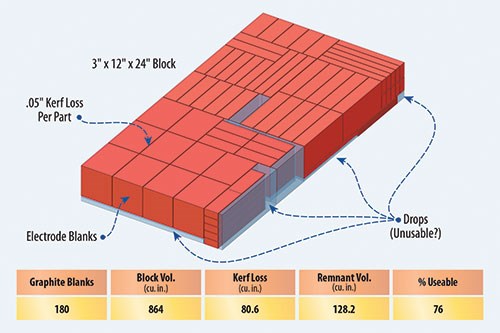

Some operations still prefer to purchase large blocks of graphite on a competitive, cubic–inch basis, rather than purchase each electrode blank to size. This gives the EDM department the luxury of same-day electrode production. However, there is a severe cost penalty associated with this technique, as there are hidden costs related to graphite material utilization. The cut graphite block illustrated in Figure 3 represents what might be typical of any EDM mold department cutting graphite on an as-needed basis. After cutting approximately 180 pieces from the block into sizes necessary to meet daily EDM requirements, almost 25 percent remains as remnant material (visible in blue), which may or may not be usable. Not only is this poor material utilization, but this shop will incur costs associated with sawing labor, equipment maintenance and accumulated remnants.

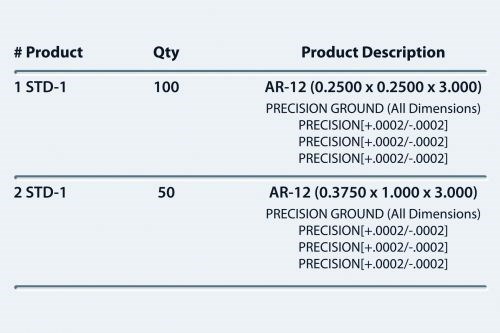

For new EDM mold requirements, purchasing large blocks of material rather than individually sized blanks seldom makes economic sense. For shops focused on mold repair operations or in emergency situations, purchasing graphite blocks may still be necessary, but this has been largely replaced by the ordering of graphite to size, as needed. In this approach, mold designers identify areas within the mold that will require EDM, create blank sizes and then indicate those specific blank sizes on a purchasing list (see Figure 4).

Set. The set-in-order 5S principle involves making workflow smooth and easy, arranging items for easy selection and preventing lost time.

Set in order is a great tool for assessing EDM productivity and for determining the need for a new machine, and/or electrode and workpiece holder technologies. If the department’s bottleneck is EDM time versus electrode milling time, then the set-in-order effort should focus on increasing EDM machine efficiency, maximizing output and avoiding those bottlenecks.

Advancements of EDM electrode and workholding techniques can be significant in dramatically improving EDM processing within many mold shops. EDM machines with toolchangers, high-speed graphite milling machines with robotics and integrated inspection capabilities all combine for a set-in-order magnitude of productivity.

Flexible workholding systems and palletization of mold components can add another level of productivity by avoiding the setup rituals of indicating and centering electrodes and workpieces. Improved repeatability also enhances the quality of a shop’s EDM-processed parts.

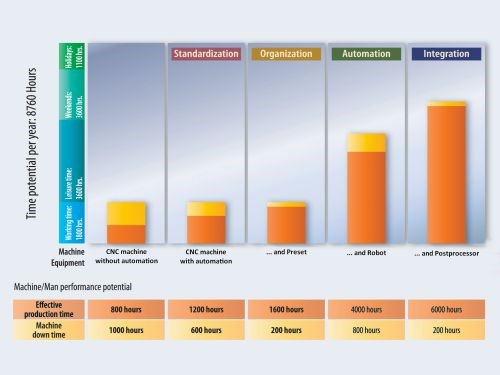

Figure 5 compares the productivity of EDM-related equipment (EDM sinkers and milling machines) with various levels of automation. The illustrated baseline assumes that, without quick-change tooling, productivity and EDM utilization (production) is approximately 800 hours annually per machine. By incorporating an integrated tooling system, this annual productivity increases to 1,200 hours, or 50 percent more productivity per machine. Another 50-percent increase in productivity can be gained by applying a pre-setting technology to the tooling. Still further improvement can be realized by applying automation to the integrated tooling system. Although many mold builders do not require full automation (or budgets won’t allow for it), the additional machine productivity it may produce can approach 6,000 hours, or more than 95 percent annual utilization. This is a significant amount of throughput for any operation.

Incrementally stocking blank sizes, by ¼-inch or 5-mm increments, is another way to streamline electrode manufacturing. Although there can be some material waste when standard electrode sizes are used, the two or three days that can be gained from using off-the-shelf pre-sized blanks promotes immediate EDM processing after a design is completed, often reducing mold delivery times.

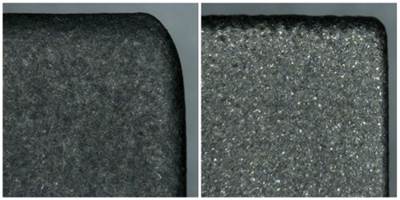

The final set-in-order consideration is a focus on further reducing mold delivery times by incorporating standard outsourcing streams for operations that typically have been performed in-house. This helps achieve more aggressive build schedules without the purchase of additional machinery or labor. External value-added options now include mold design services (the new bottleneck of EDM), components with pre-machined features, pre-assembled electronic and hydraulic packages, and even graphite blanks with pre-machined quick-change patterns (see Figure 6).

Standardize. Standardizing involves adopting best practices, establishing a standard for every process, aligning everything in its right place and maintaining high standards of workplace organization.

Technology standardization is quite apparent among machinery and tooling companies that support CNC EDM technology (see Figure 7). For example, the evolution of electrode holders into reference sizes (50, 100 and 200 mm) allows designers to establish process standards for any size EDM electrode or part requirement. These holders precisely position each tool within an EDM, making them integral to productivity improvement. Automation, toolchangers, robotics, flexible workpiece holding systems and palletization are other forms of standardization that allow precise placement of multiple parts, reducing operator input during electrode milling, EDM or inspection.

CAM systems then integrate the standard workholding and palletization systems with the movement of tooling, electrodes or probes, acting as the “glue” to hold all the pieces together. CAM dramatically reduces design time for EDM processing, enabling the designer to choose preset standards and apply a best-practice solution from a previous effort.

No matter what stage of continuous improvement your mold shop is in, or what lean tools you use, the concepts of sort, set in order and standardize are philosophies to live by in your EDM operations.

Related Content

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreLaser Welding Versus Micro Welding

The latest battle in finely detailed restoration/repair of mold materials.

Read MoreThe Benefits of Hand Scraping

Accuracy and flatness are two benefits of hand scraping that help improve machine loop stiffness, workpiece surface finish and component geometry.

Read MoreRead Next

Graphite vs. Copper Electrode Material for EDM Applications, Part 1

If you’ve been torn in the long-standing, unresolved debate over whether graphite or copper is a better EDM electrode material, here are some considerations identifying differences in cost, detail and performance to help you select the appropriate material for EDM applications.

Read MoreGraphite vs. Copper Electrode Material for EDM Applications, Part 2

Test findings and a cost of ownership model help identify the monetary impact graphite and copper electrode materials have on manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More