Build

Tips on Improving Wire EDM Productivity

By focusing on such aspects as maintenance, tooling and training, moldmakers can increase the productivity of their wire EDM significantly.

Read MoreDon't Throw That Away!

Moldmakers stand to save a considerable amount of money by repairing broken cutting tools instead of replacing them outright.

Read MoreKing Systems, Plastics Technology Division - Developing A Competitive Edge Never Ends

By investing in both technology and employee skills, King Systems, Plastics Technology Division, combines the customer service advantages of a small-sized moldmaker with the cutting-edge skills needed to succeed.

Read MoreMold Side-Actions: How, Why and When They Work

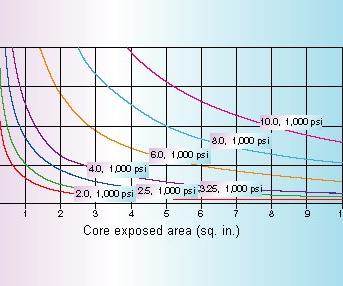

Understanding the effects of injection on the core, slide and associated components is critical to selecting the best side-action methods for a given application. This first of two articles will discuss the basic physics underlying all side-actions.

Read MoreMoldmaker-Invented Chiller Keeps Workpieces Cool Without External Coolants

A quest to improve the dry grinding process yields a chilling system that improves accuracy and increases production.

Read MoreThe Argument for Horizontal Machining Centers

Although VMCs are widely used, HMCs offer more flexibility, versatility and a number of operations in one machine tool.

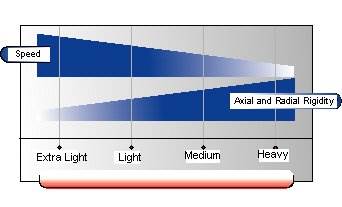

Read MoreBearing Enhancements - How New Technology Can Impact Machine Performance

By paying attention to such details as bearing selection and grease delivery systems, moldmakers may be able to increase machining speeds by up to 20 percent.

Read MoreEDM to a Shine With Silicon Powder EDM

A dual-tank, silicon powder process makes it possible to machine most tool steels to a highly reflective surface finish.

Read MoreMold Base Advancements Set a New Standard

Further standardization and more options allow moldmakers to concentrate on fine detail.

Read MoreA Stellar Hot Runner System

An off-the-shelf hot runner system helps toolmakers streak from order to shooting parts in 18 days.

Read More