Build

How to Design Hot Runner Plates

Moldmakers are often required to design and make hot runner plates for molds. Being aware of these best practices can make the process easier.

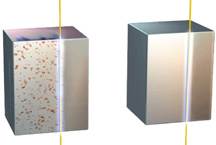

Read MoreElectrical Discharge Generator Breaks New Ground

A brand new EDM generator achieves a cutting speed of 400 mm}/min, or 37 square inch/hour, for the first time in the world, and achieves the feat of marrying the integrity of the surfaces machined with a high cutting speed.

Read MoreProducing Production Level Tooling in Prototype Timing

A new rapid solidification process machine will be able to produce finished cavities at a rate that will change the tooling industry dramatically.

Read MoreBenefiting From Hot Runner Design and Reliability

Selecting a hot runner system designed with the moldmaker and end user in mind has helped a moldmaking shop remain competitive.

Read MoreOffline Programming for Competitive Solutions

New EDM technology can improve cycle time reduction and enhance cost savings.

Read MoreRapid Prototyping: Is It a Commodity?

When considering a rapid prototyping bureau, it may be more cost-effective in the long run not to look at RP as just another commodity.

Read MoreRCT Rapidly Prototypes Product Containers - In Days, Not Weeks.

A prototype shop manager at a global cleaning, sanitation and service company thought outside the box when he rotationally molded a liquid soap dispenser in record time for testing on a production line halfway around the globe.

Read MoreFive-Axis Machining Software Offers Speed and Flexibility

Improvements in five-axis machining software are lowering the barrier for adoption by moldmakers.

Read MoreInland Technologies Bucks Trend

A unique mold shop ensures quality, on-time delivery using technology as its key tool.

Read MoreKeys to Controlling Electrode Wear

By understanding exactly the causes behind electrode wear, moldmakers can learn how to reduce or even prevent wear - increasing the life of the electrodes.

Read More