Build

High-Performance Machining - Putting It Into Practice

Most companies are looking for three basic things: to make parts faster, better and cheaper. Often, meeting these goals requires a change in process, tooling, the machine tools and/or CAM software.

Read MoreCut the Chatter - Tooling Tips to Eliminate Vibration in Cavity Milling

By learning how to eliminate vibration in cavity milling operations, a typical moldmaking shop can decrease the wear and tear on its tools, as well as boost its level of productivity.

Read MoreDesigning Plastic Components and Injection Molds for Robotically Dispensed Foam-in-Place Gasketing

While robotic technology improves design flexibility and productivity, up-front attention to component and mold design can lead to even higher gains

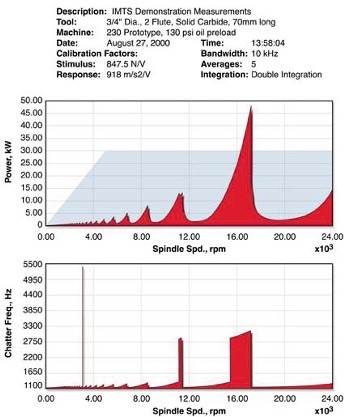

Read MoreSpindle Design for Maximum Performance

Understanding the influence of all the forces - from the type of insert to the machine base - is the key to maximum spindle, and thus, maximum machine tool utilization.

Read MoreThree Steps to a Diamond Finish

Ultrasonic profilers can be a great time saver. One veteran polisher recounts his step-by-step procedures and thoughts as he tackles one of the tool and die industry's toughest problems - intricate rib work combined with an impossibly short delivery time

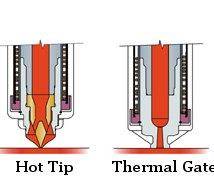

Read MoreWhy Choose a Valve-Gated Hot Runner?

Moldmakers need to be aware of how different gating technology can affect their customers when designing a hot runner system into a mold.

Read MoreThe Heat is On

A survey of the industry reveals what moldmakers have on their hot runner wish lists this year, as well as what new products and technologies hot runner companies predict are going to be "hot" in 2001.

Read MoreIntegrating Hot Runners Into Stack Molds

With stack molds becoming a more popluar technique in molding, moldmakers need to become aware of the many considerations involved in order to make hot runner integration successful.

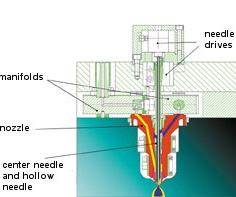

Read MoreHot Runners and Valve Gate Systems: A Moldmaking Team

Valve gates provide several advantages when using hot runners, including better appearance, safety and an overall better product. There are several types of valve gates, and it is important to choose the right one for your project.

Read MoreThe EDM Forecast: Sunny Skies

Despite the growing popularity of alternative technologies, new trends in EDM automation and product efficiencies guarantee its continued use well into the new millennium.

Read More