Bearing Enhancements - How New Technology Can Impact Machine Performance

By paying attention to such details as bearing selection and grease delivery systems, moldmakers may be able to increase machining speeds by up to 20 percent.

Demand for increased output and unparalleled quality requirements are forcing machine manufacturers to advance technologies to meet the needs of the moldmaking industry. A key component to machine performance is the spindle and its accompanying bearing design. The spindle is the workhorse of the machine and the bearings provide vital support for its performance. Selecting, maintaining and replacing these bearings throughout the life of a machine is critical for fast machining.

Machine tool spindle bearings are required to operate under a wide range of conditions. In moldmaking, the operating range can include material differences, cutting variations and cutting angles. The spindle and the bearings within a multi-purpose machine must be fully capable of achieving top accuracy under any combination of these conditions. In addition, the bearings must perform at top speeds to reduce costs through optimal machine utilization. Most new machines today are pushing the envelope of bearing technologies. In contrast, older machines do not achieve the maximum performance available to compete in today's industry. However, changes in the bearing selection within a spindle can positively impact performance through various options such as bearing design, material enhancements, lubrication and contamination control.

Bearing Design and Materials

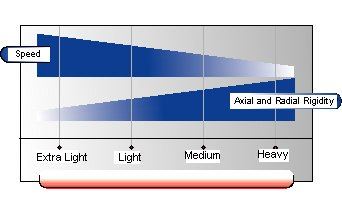

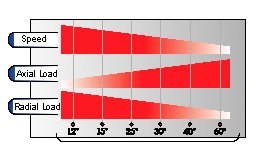

Angular contact precision ball bearings are used in a majority of spindle designs. Their design is ideal to support thrusting conditions while running at high speeds. Angular contact precision bearings offer multiple options for contact angle, preload, ball size and raceway curvatures. Contact angle choices create a tradeoff between speed, radial load and axial load (see Figure 1). In general, larger contact angles will lower the speed and radial load capability of bearings but will increase the axial load capacity, while smaller contact angles will yield higher speeds, etc. Preload, or negative clearance, also impacts spindle performance. The different options of preload - from extra-light to heavy - depend on the application and the desired performance related to rigidity and speed (see Figure 2).

Ball size also affects bearing speed. Within a given dimensional series, a smaller ball diameter results in a lower operating temperature and higher speeds, due to its smaller mass. Smaller ball diameter also generates higher bearing stiffness due to the increased number of balls. Finally, design of the bearing raceway curvatures can impact spindle speed and performance. To satisfy the constant demand for increased speeds, manufacturers are modifying the internal designs to create optimal performance in the relationship between the balls and the raceway.

Precision cylindrical roller bearings - which are usually combined with angular contact thrust precision bearings - are found in machine designs where rigidity and high radial load are required. Depending on speed and load requirements, precision cylindrical roller bearings can be found in single-row or double-row designs, and with tapered or non-tapered bores. Angular contact precision thrust bearings are available in varying contact angles.

Beyond basic bearing design, material also plays a significant role in bearing performance. Hybrid bearings, or bearings made with steel rings and ceramic rolling elements, have become popular. The most widely used ceramic material for the bearing balls is silicon nitride - Si3N4 - which offers multiple benefits. Essentially, ceramic balls create lower temperatures in higher speed applications, thus extending the range of historical speeds and extending the life of the bearing. While ceramic rolling elements are the strong trend for machine tool applications, they still suffer from negative publicity. The most common myth is that the ceramic balls are brittle and shatter upon impact during a spindle crash. In reality, these balls are comprised of silicon nitride, which is ideally suited for the balls of a bearing. While other ceramic ball materials have experienced failures, examination of failed hybrid bearings with silicon nitride balls has shown virtually no damage to the balls because they are extremely resilient.

Lubrication and Contamination Issues

Bearing lubrication also is critical to optimal performance, but is not easily changed. Spindle design dictates the lubrication methods - greased bearings, oil-air lubrication systems or oil-jet lubrication systems. Oil-jet lubrication systems offer the fastest speeds, with oil-air a close second and grease lubrication last. The lubrication method is really determined by the application requirement and the resulting machine choice. If greased bearings are required, there are new alternatives being offered to meet the increased speed requirements. These new greases are optimized for service life, temperature range, running torque and high-speed stability.

However, minimizing contamination may be the most important day-to-day requirement that is under the control of the moldmaker. While bearing appearance may be very rugged, they are the most sensitive element of machine performance. At the rpm's required from many applications, a microscopic amount of contamination can result in pitting in the raceways that can lead to catastrophic failure. The cleanliness, temperature control and maintenance of a machine will have a direct impact on machine performance. This is especially critical when rebuilding or refurbishing a spindle. Bearing installation on rebuilt spindles is the most susceptible time for potential future failures. The moldmaker should insure the use of a qualified rebuilder with a clean room, or if doing the rebuild in-house, take every precaution to eliminate any contamination.

When making a purchasing decision, the moldmaker must understand the application requirements in order to obtain top performance from their investment. Not all machines are created equal for every application. When it comes time to maintain your investment, understanding your choices also is critical. Maintaining a clean, temperature-controlled environment is essential for machine performance. It is ideal to replace the original machine with the original components. However, sometimes application needs change, and understanding the modification options of the changing technology may help you reach additional optimization of existing machines. By combining the elements of basic bearing design, material enhancements, lubrication options and controlling contamination, the maximum permissible speed of machine tool spindles could be increased by 20 to 30 percent.

Related Content

The In's and Out's of Ballbar Calibration

This machine tool diagnostic device allows the detection of errors noticeable only while machine tools are in motion.

Read MoreOEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.

Read MoreSolving Mold Alignment Problems with the Right Alignment Lock

Correct alignment lock selection can reduce maintenance costs and molding downtime, as well as increase part quality over the mold’s entire life.

Read MoreDevelopments in High-Speed Machining Technology

There have been many exciting developments in high-speed machining relative to machining centers and controls, tooling and CAD/CAM systems.

Read MoreRead Next

Are You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read More