Build

How to EDM Large Surfaces Through Diesinking

A new technology allows moldmakers to control the EDM process and to ensure a uniform surface finish.

Read MoreMilling Advances Increase Productivity

Keeping on top of new advances in cutting tools can keep moldmakers profitable.

Read MoreLonger Electrode Life Benefits Moldmakers

New electrode-making process makes copper/tungsten electrodes last twice as long as graphite - with a better finish.

Read MoreThermal Toolholding Yields Benefits for Moldmakers

By using thermal toolholding, moldmakers can achieve improved accuracy and greater tool life, as well as better mold surface finish.

Read MoreKeeping Your Balance

With the ever-growing popularity of high-speed machining, proper tool balancing has become a crucial element in moldmaking. However, it is important to know your options before purchasing a balancing system.

Read MoreIllinois Mold Shop Increases Productivity with Hole Driller

A high-speed CNC hole driller EDM machine allows Creative Die Mold to stay on the cutting edge.

Read MorePart 2: New Tool Concepts for Machining Dies and Molds

The use of multifunction inserts is a significant geometrical development - making it possible to machine various operations with a single insert.

Read MoreHow to Work Better, Faster and Cheaper

While moldmakers may have difficulty competing with foreign markets on cheap labor, they can compete by finding new ways to build molds faster and cheaper with high-quality results.

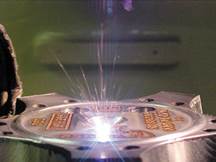

Read MoreLaser Engraving Enhances Mold Design

Consideration should always be given to the optimum cost/quality relationship when choosing laser engraving.

Read MoreHow to Control Excessive Tool Wear

By calculating feeds and speeds properly, moldmakers can reduce tooling costs, have less machine downtime and see less scrap due to worn tools.

Read More