Thermal Toolholding Yields Benefits for Moldmakers

By using thermal toolholding, moldmakers can achieve improved accuracy and greater tool life, as well as better mold surface finish.

Decreasing production time and increasing accuracy are important considerations in all metalworking operations, but particularly in the time-consuming and exacting area of moldmaking. Now, a growing number of moldmakers are discovering that heat-shrink - or thermal - toolholding (i.e., using heat to expand the toolholder and then letting it cool around the tool's shank) can help on both counts.

Thermal toolholding isn't new. Systems employing heated air supplemented with open gas flames were used for a number of years in high-volume production environments, but the technique saw limited use, as the tighter hold delivered by the technique often didn't seem to outweigh the disadvantages caused by the cumbersome equipment cost and extra time required.

All of this began to change in the latter half of the 1990s, however, with the increasing use by the auto industry of light metal parts and the high-speed machining centers needed to machine them. At these higher rates of speed (15,000 rpm and above), it soon became evident that conventional toolholding systems were often inadequate in terms of tool clamping forces and concentricity. Out-of-round errors larger than 5.0 mm, particularly at higher spindle speeds, result in enormous strain on the machine spindle. This decreases tool life and increases the danger of producing out-of-tolerance parts. Additionally, the last few years have seen the increased use of circular interpolation machining, with its accompanying high metal removal rates. This generates large radial forces that necessitate, for safety reasons, much higher tool clamping forces. And finally, tooling must be securely and reliably held in place if it is to achieve its optimum service life, particularly at higher rates of speed.

Thermal toolholding, with its numerous advantages, provides a solution. These advantages include:

- Complete contact with all surfaces of the cutting tool shank by the toolholder, in effect forming a monoblock tool/toolholder.

- The rigidity needed to tolerate large radial forces.

- Excellent concentricity.

Still, the original drawbacks continued: Open gas flames posed safety hazards and long cooling-off periods between securing and the removing of tools ate into production time. To this was added the difficult problem posed by high-speed steel (HSS) tooling, which could be secured but then not easily removed because the tooling and the toolholder were made from materials having the same coefficients of thermal expansion. All this changed, however, in 1999 with the introduction of a thermal toolholding system that relies on inductive heating rather than open flames.

Inductive Technology Breakthrough

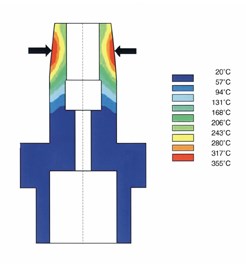

The key to the success of the new thermal system is its very fast heating of the toolholder in a specific area or zone. A metal disc is used to shield the tool from the magnetic force lines, which do the actual heating. This allows HSS tools to be used with the system.

The grip of a shrinking chuck is based on proportional temperature expansion of solid materials. The effect to the chuck of increasing temperature causes the inner diameter to increase in size. With the new system, the cutting tool is then inserted into a heated and expanded bore of the chuck, and a high radial clamping force is applied as it contracts to its normal size at room temperature. Provided the expansion is in the elastic range of the chuck's material specification, the clamping operation is reversible and can be repeated as often as required.

The material for the toolholder employed in the new thermal system is a special hot work tool steel capable of being used at temperatures up to 500'C (930'F). The contraction (shrinking) temperature of 300' to 340'C (572' to 644'F) is achieved in less than 10 seconds and results merely in changes in the elastic region of the metallurgical structure (microstructure). In trials consisting of 5,000 operational cycles, there was no evidence of through hardening or embrittlement of the microstructure.

The long cooling-off periods that characterized earlier thermal toolholding systems were reduced by the fast and localized nature of inductive heating, and by the use of a large, finned aluminum heat exchanger that surrounds the toolholder. Heat is further dissipated by using an integrated forced air system. Depending on the diameter of the toolholder, the toolholder can be handled manually in 30 to 60 seconds.

Migrating to the Mold Arena

Key factors for the clamping process are the heating time, the resulting temperatures and the flow of heat energy through the chuck. Medium frequency inductive heating allows precise control of these elements. Importantly, the compact size and relatively automated nature of the new inductive heating systems has for the first time made thermal toolholding a practical option for smaller facilities, including mold and tool shops.

What's the advantage for mold and tool builders? First and foremost, the new inductive heating thermal toolholding systems greatly improve toolholder accuracy. They also provide a more secure grip on the tool, and are naturally balanced because there are no setscrews as with endmill holders, and no collet nuts, thus improving tool balance. This combination of the excellent concentricity, natural balance and high clamping forces contributes to improved cutting and greater tool life. It also provides better surface finish on the die or mold, which means less bench time - a key factor in boosting mold and die productivity and profitability.

These combined benefits of improvements in production time and quality, reduced bench time and decreased tooling budgets is making mold and die a key growth sector for the new thermal toolholding systems.

Related Content

Maintaining a Wire EDM Machine

To achieve the ultimate capability and level of productivity from your wire EDM on a consistent, repeatable and reliable basis, regular maintenance is a required task.

Read MoreMoldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

Read MoreAdvantages and Disadvantages of Copper and Graphite Electrodes

Both copper and graphite provide approximately the same end result, so it is important for a shop to consider the advantages and disadvantages of each material in order to discover what would work best in their shop floor environment.

Read MoreRevisiting Some Hot Runner Fundamentals

What exactly does a hot runner do? If you’ve been in the injection molding industry for any length of time, you might think the answer is obvious, but it is not.

Read MoreRead Next

Are You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More

.png;maxWidth=300;quality=90)