Build

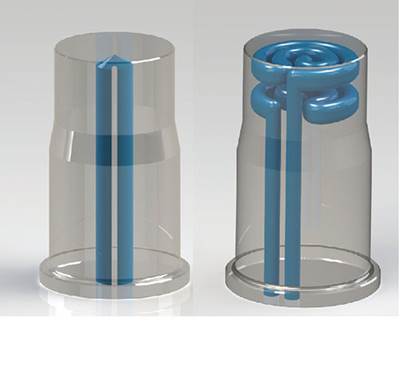

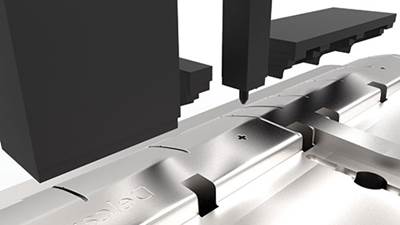

Mold Cooling Options

A look at three options for integrating conformal cooling into a core or cavity with an emphasis on vacuum brazing.

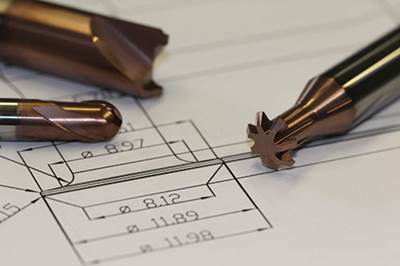

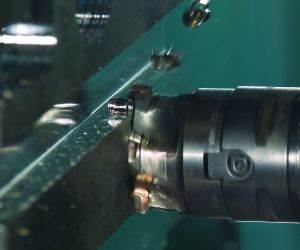

Read MoreCutting Tool Considerations as Mold Complexity Increases

A look from the shop floor at some of the factors to consider during your cutting tool selection decision-making process to optimize your mold machining operations.

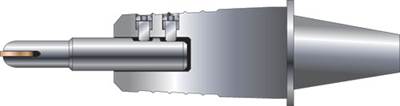

Read MoreAngles Stop Negative Areas from Undercutting the Injection Process

The new vertical lifter design provides a range of advantages during mold construction: space savings, easier machining and simplicity of assembly.

Read MoreConquering the Complex Task of Tool Optimization

Standard coatings can help, but to achieve really impressive results all the factors must be coordinated with one another—from the base material of the tool to the post treatment of the coating.

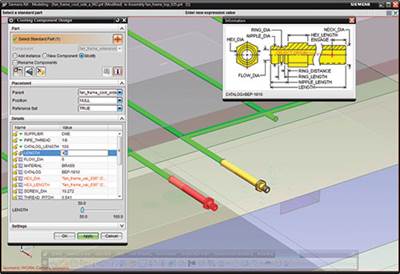

Read MoreThink Metric, Part 3

Insight from several technology suppliers—in design software, mold components, programming, machines, cutting tools and measurement equipment who have been following the metric trend—may help to make the transition a smooth one.

Read MoreIntegrating Electrode Production

How CAD/CAM can help make the design, machining and inspection of electrodes completely integrated.

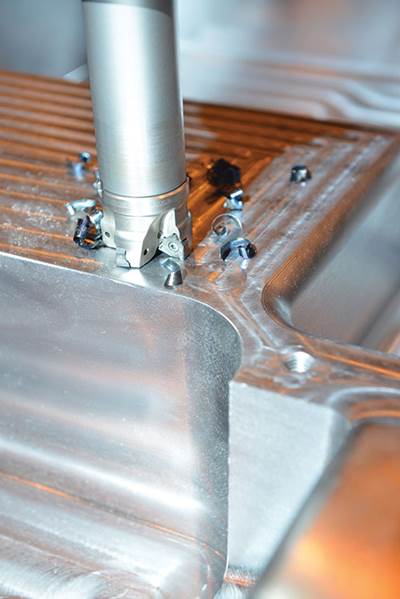

WatchHow to Optimize Moldmaking Milling Operations

The lead angle of your cutter has a dramatic effect on not only the chip that you generate, but also the cutting forces in both the axial and the radial directions.

WatchSupercharging Rough Machining Performance with Advanced Tooling

What is amazing is that the shop is confident it could run the Seco cutter at 500 ipm if the machine was capable. It is this reason that Build-A-Mold is in the process of acquiring newer, faster equipment.

WatchSiemens and KUKA Announce Cooperation

Joint solutions offered: integrated, operator-friendly loading of machine tools using robots; integration of robotics and CNC solutions for machining workpieces with robots; strengthening the fundamental idea of integrated production processes; and, development of new applications in lightweight construction.

Read More