Build

Angling for “Big” Advantages in Automotive Tooling

This shop hopes to capitalize on growing opportunities in a different market by adding to its large-part machining capacity.

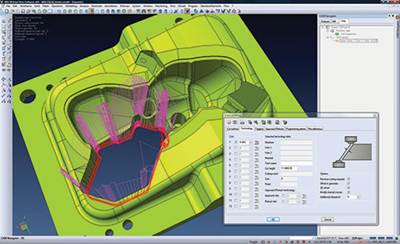

Read MoreImprove and Simplify Wire EDM

A CAD/CAM system with dedicated wire EDM functionality should allow the user to select a specific machine from within the system and apply the conditions to the machining operations.

Read MoreBuilding a Mold in Fewer Setups

Current machine tool technology can reduce complex elements of moldmaking while increasing mold quality and accuracy.

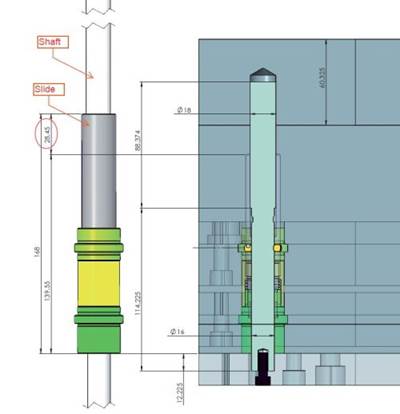

WatchStraight and Simple

An internal vertical lifter system enabled this shop to design a mold that releases a series of undercuts without requiring angled machining operations.

Read MoreA Supporting Role

This shop solved a critical application problem with help from a distributor in the know about potential solutions and a responsive supplier to help implement them.

Read MoreAchieving Accurate Temperature Control with Your Hot Runner Controller

The right hot runner controller is key to producing high-quality, complex medical parts.

Read MoreBelieve the Hype

Technology and service providers invested in additive manufacturing have taken the hype and brought it to practicality.

Read MoreThe Value of Insourcing and Standardizing Component Work

To become more competitive, this mold manufacturer established a components division to build a growing selection of its own mold components.

WatchCarving out Savings at the Front End

Positive-geometry cutting tools help this shop double-down on a key time-saving strategy by reducing machining time on aluminum MUD frame inserts.

Watch

.jpg;maxWidth=400;quality=70)