Build

Wiping the Slate Clean with a Brand-New Facility

“After the two-week transition period, we were operating smoother than we were at our previous facility.”

Read MoreSoft Wire Threading for Wire EDM’ing: Tips for Success

Look for EDM equipment that provides improved wire processing during the AWF cycle. Technology should include a way to precisely control the wire tension and energy used to cut the wire.

Read MoreMega-Cell: Moldmaking Automation

The Mega-Cell is a production system that ties together all available opportunities to automate and control the process.

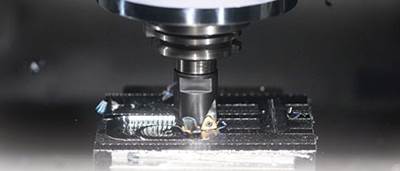

WatchMold Roughing

Tolerances and finishes on the Buss Precision's molds are tailored to the specific project, but most work is held to +/-.0002 tolerance on multi-cavity components, cavity, cores and parting lines.

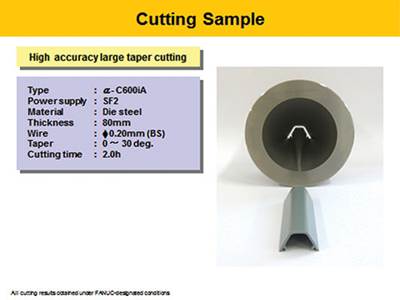

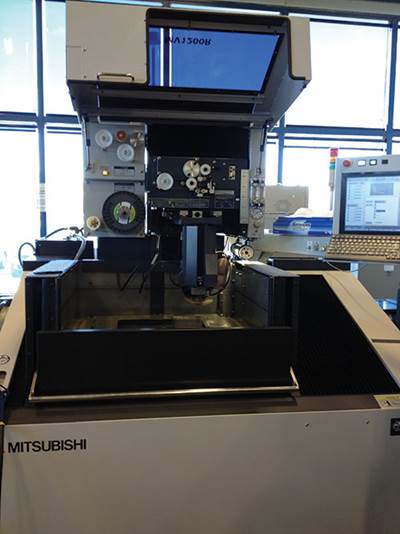

WatchNew EDM Pushes Performance and Precision

“This machine has changed wire EDM in a way that the machines I’ve operated have not been able to do, because it cuts substantially faster than its predecessors, yet it consumes about 40 percent less wire.”

Read MoreFinding the Right High-Feed Indexable Milling Tool

The value of versatility and reliability in your high-feed machining solution.

Read MoreManpower, Machine Time Maximized with Highly Accurate VMC

“Using highly accurate machines allows more efficient utilization of manpower and machine time—saving time and money for the customer and making BPM more profitable.”

WatchRaising the Bar on Better

A look at one project to move away from traditionally customized moldmaking toward a level of complete automation that raises the bar on accuracy, repeatability and control.

WatchTraditional Labor Values Meet Linear Technology

What GW gained was high reliability, improved speed/throughput without sacrificing accuracy or quality and a high level of satisfaction from the operators, on all the machines.

Read MoreUnderstand Your Tools

"Challenge us to help you do what you do more effectively." Those were the words of Ingersoll Cutting Tools President Chuck Edler as he kicked off the Die & Mold Seminar this morning, which honed in on understanding the precise tools necessary for the delicate processes of mold manufacturing--milling, high-volume roughing, high-feed roughing, aluminum machining, gun drilling and hole making to name a few.

Read More