Build

MoldMaking Technology's September Issue Is Now Available

The digital September issue of MoldMaking Technology magazine is now available. The cover story highlights how even the smallest mold shop can afford an integrated shop floor management system that allows for the management of every business transaction. Other content covers automation, machining and cutting tools with video components.

Read MoreHaas Automation Pledges $1 Million to Machining/Mfg Ed

We need more manufacturers and suppliers to commit to training our future workforce. These funds will help students in U.S., Canada, Mexico, Europe and South Africa.

Read More“Fixing” to Get More Accurate, Increase Productivity with Automation

The Roku-Roku machine, EROWA workholding system and the EROWA Robot Multi form the production team. Optimally used, this team can deliver up to four times higher productivity.

WatchOne Door Closes, Two More Open

The money from the sale of the AM portion of VistaTek’s business allowed the company to add equipment—and employees.

Read MoreEducation and Training Triumphs

The 2013 Leadtime Leaders detail their apprenticeship training and educational programs—and the rewards they reap.

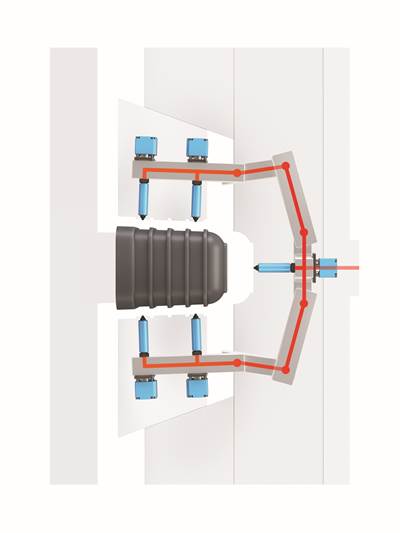

WatchEnhancing Product Quality via Conformal Cooling Design

A look at two cases demonstrating the value of CAE software at the pre-tooling stage.

Read MorePreventive Maintenance Makes Good Dollars and Sense

By keeping up with your recommended preventive maintenance (PM) schedule, you can reduce your chances of having a catastrophic breakdown.

Read MoreHow to Tackle Sophisticated Molds

Considering that semi-finishing and finishing processes account for 70 percent of the milling of a mold, it becomes obvious that using such a system can lead to huge productivity gains.

Watch