On-Machine Texturing and Polishing

Laser technology highlighted at DMG MORI’s recent “Innovation Days” event enables users to texture molds still fixtured on the machining center. Plans are currently in the works to similarly automate polishing.

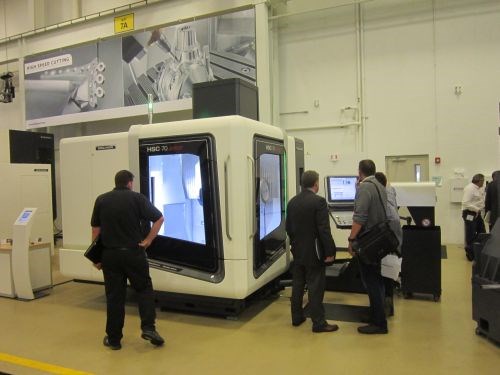

DMG MORI's recent “Innovation Days” event in Chicagoland May 6-9 had plenty to offer our particular corner of the industry. The HSC 70 Linear, shown above, is just one example. Among other features valued by moldmakers, the machine offers simultaneous five-axis or 3+2 machining capability; linear motors for smooth, frictionless motion; active cooling of the motors and spindle; and CNC functions specifically for high speed cutting.

However, this machine tool builder also understands the fact that some mold work still requires old-fashioned elbow-grease. To alleviate that burden, the company has directed recent development efforts beyond just raw machining capability. The result? By year's end, machines like the HSC 70 could very well contain technology that automates one of the most time-consuming and labor-intensive processes in any mold build: polishing.

For operators, the operation will proceed somewhat similarly to a common milling routine. However, rather than retrieving a typical cutter from the ATC, the machine will employ special rotary “brush” tooling. Beyond the time savings that come with automating the process, this technology is expected to minimize setups and part handling. Company personnel emphasized that this new polishing concept is still in the works, but rest assured we'll provide more information as soon as it's available.

Meanwhile, some mold manufacturers are already realizing similar advantages for another operation, as I discovered when I asked about the part below. Although the part itself has nothing to do with moldmaking, the way it was created has wide-ranging implications. The entire part, including the two different textures visible on the surface, was produced on a machining center in a single setup.

That’s not to say these textures were milled. Rather, they were created by fiber laser heads that fit in the toolchanger of a Sauer Lasertec five-axis machining center. Said to be particularly useful for suppliers of automotive interior tooling, this technology can eliminate the need to send mold components to outside chemical etching houses. Company representatives also noted that it is particularly beneficial for molds that require multiple textures, because laser heads can be changed just like a typical cutting tool.

Of course, the biggest highlight of the company’s Sauer Lasertec line—and perhaps even the “Innovation Days” event as a whole—was the ability to combine additive and subtractive manufacturing to provide new options for making parts. Other prominent displays included a new machine “skin” and a common control interface, CELOS, both of which I covered during a recent trip to the company’s Pfronten, Germany factory. Finally, a number of machines—including a new five-axis model—were introduced to the U.S. market for the first time. Visit the company’s website for more information.

Related Content

-

MMT Chats: Eliminating the Noise to Stay Focused on the Customer

Metro Mold & Design joins me to discuss the value of the 80/20 rule as a business strategy, its talented cross-functional team, the role of automation in mold building and molding, and the continuing impact of COVID-19.

-

Hands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

-

Machine Hammer Peening Automates Mold Polishing

A polishing automation solution eliminates hand work, accelerates milling operations and controls surface geometries.

.jpg;maxWidth=300;quality=90)