Plan Your Workholding for Improved Productivity

Choosing and organizing the right workholding can result in significantly improved machine efficiency, and it is essential for reaching any machine’s full potential.

Choosing and organizing the right workholding can result in significantly improved machine efficiency, and it is essential for reaching any machine’s full potential.

Two simple methods for improving efficiency and spindle uptime are increased workpiece access and faster changeover between jobs, which can both be relatively inexpensive to accomplish when compared to a new machine and additional human capital.

Magnetic workholding is one way to improve access to the workpiece, as it enables accessibility with as many as five faces with one set up, allowing for longer run times and better accuracy. Magnetics also provide a vibration-dampening effect that improves surface finish and tool life. In addition, electro-permanent milling magnets do not need electricity to maintain their magnetic fields. They also are able to clamp more than 200 pounds per square inch of surface contact, providing safe and secure clamping.

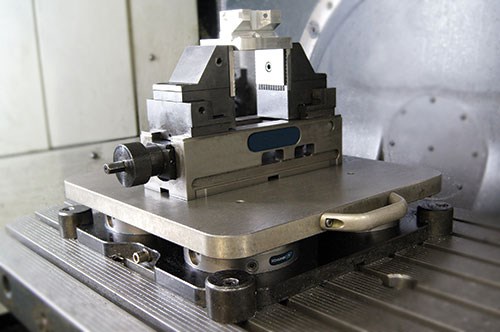

A quick-change pallet system can be used to speed up change-overs and is a simple way to automatically gain efficiency. It offers the ability to prep a job offline and quickly drop it into a machine with as much as 5 microns (0.0002 inch) repeatability.

Such quick-change systems can be incorporated onto a standard vise, custom fixture or even directly into the back of a mold. This can be extremely beneficial when machining molds, as it can be used anytime a mold returns to the machine for rework, measuring, etc. The quick-change system also allows the mold to be returned to the original machine within 5 microns of where it was originally machined. Therefore, even the original program with its offsets can be run, which eliminates the need for reprogramming.

Quick-change pallet systems, similar to magnets, also increase the machine table’s capacity, because they can effectively locate and clamp in a single step from the underside. In addition, these systems provide machine interchangeability. When a standard is set in a shop, a pallet or part can be quickly and easily moved from one machine to another, or even to a coordinate measuring machine, in a matter of minutes.

Both magnetic workholding and quick-change pallet systems can provide rigid, secure and efficient workholding for machining at a reasonable cost, and with payback possible in about a year.

Related Content

-

MMT Chats: Solving Schedule and Capacity Challenges With ERP

For this MMT Chat, my guests hail from Omega Tool of Menomonee Falls, Wisconsin, who share their journey with using enterprise resource planning (ERP)—and their people—to solve their schedule and capacity load monitoring challenges.

-

Predictive Manufacturing Moves Mold Builder into Advanced Medical Component Manufacturing

From a hot rod hobby, medical molds and shop performance to technology extremes, key relationships and a growth strategy, it’s obvious details matter at Eden Tool.

-

Top 10 Topics to Cover During an ISO 9001 Manufacturing Audit

Take a look at this practical hands-on approach to conducting a quality audit.

.jpg;maxWidth=300;quality=90)