Analysis

The Benefits of a Remanufactured CMM in Your Shop

The only way to economically meet the need for a large gantry CMM with an uncommon measuring envelope was to find an existing one, rebuild it and remanufacture it.

Read MoreHas the Molding Machine Been Tested?

Knowing how a machine is tuned will improve your decision making for mold construction and adjustments.

Read MorePart One of a Three-Part Series Five Steps for Improving Your Shop’s Maximum Productivity

Learn how to evaluate your shop’s productivity and begin increasing it by considering the variables of implementing hard milling and high-speed machining.

Read MorePart Three of a Three-Part Series Laser Beam Hardening: A Flexible Tool for Wear Protection

The development of a new laser beam scanning system for the heat treatment of tool steels and various metals.

Read MoreBreaking the Mold in Mold Development

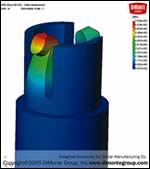

Integrated analysis capabilities streamline mold design.

Read MorePart One of a Three-Part Series Metal Laminated Tooling-Process Chain

Results from laminated tooling testing show that this technology has the capability for an enormous reduction in cycle time via the integration of a conformal cooling system.

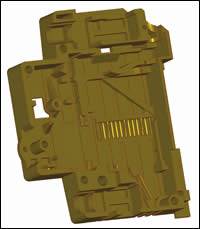

Read MoreMoldmaking in 3-D

Laser scanning helps moldmakers to improve reverse engineering and inspection tasks for their molds.

Read MoreActivity-Based Costing for Mold Shops: The ABC Process and Its Cost

Mold shops conducting an activity-based analysis can obtain valuable information about costs and profits, and answer those what if questions..

Read MoreActivity-Based Costing For Mold Shops: Benefits of ABC

By using ABC to analyze outsourcing, cost cutting and performance measurement techniques, moldmakers can know the real cost of running a mold shop.

Read MoreActivity-Based Costing For Mold Shops: An Improved Costing Method

A different method of cost analysis helps mold shops compute costs more accurately and increase profits in the long run.

Read More