Part One of a Three-Part Series Metal Laminated Tooling-Process Chain

Results from laminated tooling testing show that this technology has the capability for an enormous reduction in cycle time via the integration of a conformal cooling system.

Share

For the manufacturing of complex formed tools, Fraunhofer USA works together with industry partners on solutions for high-speed laser cutting, packaging and adding steel sheet cutouts. Key technology is the joining method of the metal sheets. The most suitable connecting technology must be selected according to requirements such as quality, surface quality and production costs. In order to integrate a complex cooling system in injection molds a temperature-steady connection of the sheet metal lamellas is necessary. However, the laminated cooling system can be separated from the tool body. That allows other possibilities for the connection of metal sheets.

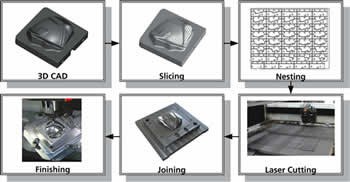

Metal Laminated Tooling Process Chain

Three-dimensional CAD data of the tool to be manufactured are read into the CAD system, using standard interface formats (STEP, IGES, STL), as can be seen in Figure 1. Subsequently, the tool is sliced into single cross-sections. In addition, the layer thickness that must be determined before is set, considering metal sheet tolerances or shrinkage of the bonding material (glue, soldering metal). After slicing, the single cross-sections are arranged on a metal sheet panel. The cross-sections are cut out by laser beam and are, subsequently, joined by various bonding technologies. Finally, the tool is finished by milling, EDM, polishing and heat treatment.1

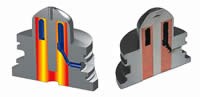

Cycle Time Reduction by Conformal Cooling Systems

With the layer technology it is possible to integrate complex tempering systems in injection molds or die-casting tools, as can be seen in Figure 2. An optimization of the tools can be done by FEM-analysis or with a thermal image camera. In this way, the cycle time can be reduced dramatically and distortions of the parts are reduced because of the homogeneous tool temperature.

If a laminated cooling system should be integrated, the tightness and heat conductivity of the laminated tool must be very high.2 Suitable connecting procedures are hard soldering and high temperature brazing.

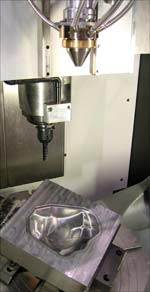

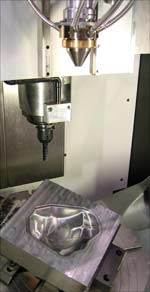

Metal laminated tools, which are manufactured by high temperature brazing, are hermetically sealed and possess good heat dissipation. After brazing the laminated tool is finished by milling or polishing.

The strength of hard-soldered connections depends primarily on the applied soldering procedure. High temperature brazing takes place in vacuum or in an inert gas atmosphere. The strength of the connections—from low to highly alloyed steel—reaches the strength of the basic material. Most used soldering metals are nickel, silver and copper based. For the production of laminated tools for the high temperature range only high temperature soldering metals on nickel basis are applicable due to the enormous thermal load of the nickel alloy, whose heat resistance is enough to 1472oF (800°C).3 Even with high operating temperatures, they possess firmness that is sufficient for injection molds or die casting tools.

High temperature brazing has high demands for the preparation of the joints. The samples were therefore manually cleaned from oxide coatings and then cleaned afterward with ethanol and/or acetone. Subsequently, the up-sprayed soldering coating was dried (10min with 248oF (120°C) in a furnace. After that, the lamella package was soldered in the furnace under inert gas atmosphere at 1940oF (1060°C).

In the next process step, finishing took place by means of milling and polishing. Finally the tool was installed in the tool framework and tested with a project partner. In summary, the following statements can be made for testing:

- The laminated tool showed up compactly and the layer interfaces are almost non-porous.

- The integrated cooling system proved suitable; no leakage occurred.

- In these experiments, the cycle time with a conventionally manufactured and laminated tool half could be reduced by 35 percent.

Laminated Cooling Insert

Another example of integrated cooling is given in Figure 3. The customer requested special features for cooling and part quality:

- Tool steel was required.

- A layer structure in the tool surface was not acceptable.

- The cooling system should be very close to the tool contour.

- The injection channel of the cavity nozzle side and the ejector pins must be avoided by the cooling system.

For this special application a metal laminated cooling insert was developed (see Figure 3). In particular, the tool contour and cooling system were separated. In this way, the tool contour can be manufactured by conventional manufacturing technologies (e.g., milling, turning or EDM) and the laminated cooling insert is integrated afterward.

This has several advantages:

- Economical effects: cycle time reduction can be realized for mass production tools.

- No limitations concerning materials (e.g., tool steel for contour, copper for insert).

- Easier joining of the sheets. For injection molds, the metal sheets could be glued because the injection temperature and pressure won't be reached at the internal cooling system.

- In some cases, just clamping could be sufficient.

- The laminated structure is inside; therefore, there is no layer structure in the tool surface.

- The insert can be integrated after heat treatment.

If the laminated cooling system is joined by the mentioned high temperature brazing, the application field widens to the high temperature range. In this way, the manufacturing of die pressure casting and hot forming tools with an integrated complex tempering system is possible.

Summary

The investigation on laminated tooling has shown that this technology has the capability for an enormous reduction of the cycle time. This is done by integration of a conformal cooling system. An optimization of the tools can be done by FEM-analysis or with a thermal image camera. In this way, the cycle time can be reduced dramatically and distortions of the parts are reduced because of the homogeneous tool temperature.

Injection molds require a perfect bonding in order to produce a high surface quality and a dense connection of the lamellas. The investigations showed that the developed process chain for high temperature brazing is suitable for the manufacturing of tools with integrated cooling systems. Moreover, a laminated cooling insert system was developed, which enables cycle time reduction for mass production tools.

Eric Stiles is with Fraunhofer USA, Inc., Center for Coatings and Laser Applications; Dr. Anja Techel and Dr. Steffen Nowotny are from Fraunhofer IWS, Germany; and, Prof. Dr. Eckhard Beyer is with Fraunhofer IWS and with the University of Technology at Dresden as Chair for Surface Engineering and Thin Film Technology at the Institute for Production Technology, Germany.

Fraunhofer Background

The Fraunhofer Society is Europe’s largest and most renowned organization in applied and technical research with more than 11,000 scientists and engineers working on customer solutions in 56 institutes.

Fraunhofer CCL is committed to meeting the needs of the customer. It dedicates the full resources of its operation performing top notch R&D to customer’s specifications. Scientists and engineers provide customers with the all-encompassing service so important in today’s technologies. It has formed close partnerships with Michigan State University and Penn State University. It also networks with companies that provide state-of-the-art technology in the field of coating and laser technologies. In addition, a close partnership exists between the Fraunhofer CCL and the parent institute Fraunhofer IWS Dresden in Germany.

Fraunhofer USA was incorporated in 1994, in Rhode Island as a non-profit organization. It is the U.S. subsidiary of the Fraunhofer Society with headquarters in Plymouth, MI, and research centers throughout the U.S. The centers perform contract research for government and industry customers based on the expertise of their parent institutes in Germany. Fraunhofer USA’s Center for Coating and Laser Application is a consulting and engineering operation also located in Plymouth, MI and works closely with the parent institute Fraunhofer Institute for Material and Beam Technology (IWS) located in Dresden, Germany.

References

- Himmer T., Techel A., Nowotny S., Beyer E., “Recent Developments in Metal Laminated Tooling by Multiple Laser Processing,” Proc. 13th Solid Freeform Fabrication Symposium, Austin, TX, S. 466-473, August 2002.

- Nakagawa T., Kunieda, M., Liu S., “Laser Cut Sheet Laminated Forming Dies by Diffusion Bonding,” Proceedings of 25th International MTDR Conference, S. 505-510, 1985.

- Dorn L., “Hartlöten: Grundlagen u. Anwendungen,” Expert Verlag Sindelfingen, 1985.

- Himmer T., Techel A., Fraunhofer IWS U.S. patent pending, DE 103 10 987.

Related Content

Tips for Tackling Mold Design, Machining, Cutting Tool and Wear Challenges

Tips for tasks ranging from reducing risk in part design and taking advantage of five-axis machining to refining cutting tool performance and reducing wear with guiding and centering systems.

Read More3D Printing Enables Better Coolant Delivery in Milling Operations

Just like 3D printing enabled conformal cooling channels in molds, additive manufacturing is now being used to optimize coolant delivery in cutting tools.

Read MoreMoldmakers Deserve a Total Production Solution

Stability, spindle speed and software are essential consideration for your moldmaking machine tool.

Read MoreMold Innovations Power Unique Auto Lighting Elements on Hummer EVs

Diamond machining, electroforming of micro-optical inserts and modified latch-lock system help injection molds produce unique forward lighting elements.

Read MoreRead Next

Part Two of a Two-Part Series High Power Laser Technologies And Moldmaking

Using high power laser cladding for rapid tooling and tool repair.

Read MorePart Three of a Three-Part Series Laser Beam Hardening: A Flexible Tool for Wear Protection

The development of a new laser beam scanning system for the heat treatment of tool steels and various metals.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More