Analysis

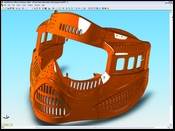

Does Your CAD System Support Design and Validation In One Window?

Implementing one tool that can handle part design, mold design, part structural analysis and mold filling analysis is becoming a necessity for today’s mold shops.

Read MoreCrash Test Genius

Toolpath verification software has evolved to permit simulation of the entire machining system.

Read MoreInvestments in Productivity: Automation Integration In the Toolroom

By integrating machining, workpiece and cutting tool management, CMM verification, and a Web-based video and control system, a completely integrated cell producing fully qualified electrodes through automated manufacturing can be created.

Read MoreTeam Approach Is Key to Proper Inspection

Using a group rather than one person and changing the order of inspection is a win-win for this moldmaker—repeatable results with no rework.

Read MoreModern Software Solutions in Measurement Metrology Improve Mold Build and Verification

Inspection and verification that the mold and the products it yields comply with the master CAD design are open to the benefits from modern development in CAD/CAM technology.

Read MoreAdditive Fabrication Facilitates Successful Injection Mold Design and Build

The appropriate use of RP additive models in conjunction with injection mold toolmaking has a positive impact on communication and verification, styling and ergonomics, and fit and functional issues.

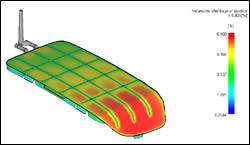

Read MoreComplete Mold Filling Analysis Helps with Automotive Design Challenges

Intier Automotive relies on CAE consulting for automotive design and innovation.

Read MoreCorrective Action Analysis

How to properly format a corrective action report in your shop database

Read MoreJustification Through Data

Including position analysis in your data collection practices will help you make smarter maintenance and mold design decisions.

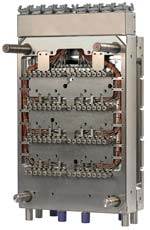

Read MoreThree Influences that Are Critical to Mold Performance

Analysis, integrated design and value-engineering play an important role in choosing the right hot runner supplier.

Read More