VISI l Hexagon

46444 Hexagon Way

Novi, MI 48377 US

248-351-9300

info.ps.mi@hexagon.com

visicadcam.com

IS THIS YOUR COMPANY?

As Seen On MoldMaking Technology

VISI l Hexagon Supplies the Following Products

- CAD (Computer Aided Design)

- CAE (Computer Aided Engineering)

- CAM (Computer Aided Manufacturing)

- CNC Software

- Data Management Software

- Data Translation Software

- EDM Services

- Inspection/Measurement Services

- Manufacturing Automation Software

- Mold Design Services

- Mold Flow and Simulation Software

- Mold Quoting Software

- NC Simulation and Verification Software

- Reverse Engineering Software

Editorial, News, and Products

-

Hexagon Acquires TST Tooling Software Technology LLC

The master reseller of VISI and PEPS software in the U.S. and Canada will be consolidated within Hexagon’s Manufacturing Intelligence division.

-

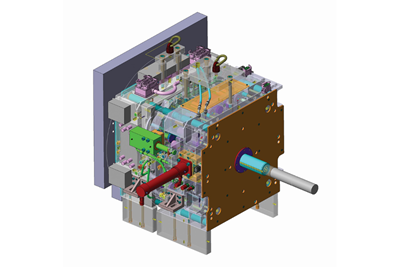

Enhanced CAD/CAM Software Optimizes User Experience and Design Process Speed

VISI 2022.0 from Hexagon offers CAD and CAM updates from optimized and new commands, 30-60% 3D roughing operation calculations and easier file transfer between versions.

-

Leadtime Leader Q&A: Embedded Quality Control

Precise Tooling Solutions shares current capabilities and a glimpse of the changes occurring inside their manufacturing operations when it comes to inspection and measurement.

-

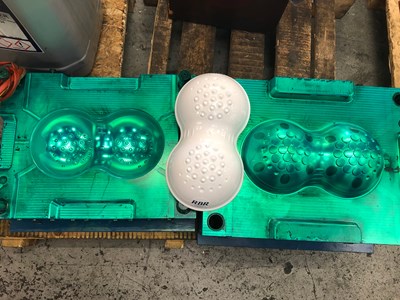

Comparing 3D-Printed Conformal-Cooled Steel Molds to Aluminum Molds

While 3D-printed conformal coolant lines in steel injection molds reduce production costs and improve part quality, aluminum molds can yield similar results faster and at a lower cost.

-

How to Improve the Flow of Mold Repair and Engineering Changes

A new perspective on competition, training and workflow redefines this shop’s core competency in repair and engineering changes, and charges the team toward continuous improvement.

-

Accu-Die & Mold Excels in Die Cast Tooling with a Focus on Service, Engineering, and Precision Manufacturing

Accu-Die’s highly trained workforce, well-equipped shop are key to meeting the challenging demands of die-cast mold production.

-

American Quality Molds Announces Standard Option Bases in VISI

American Quality Molds has been selected by TST/VISI to be a preferred supplier within their software package.

-

Extensive CAD/CAM Functionality Helps Complete Medical Mold Build in 6 Weeks

The industry has been talking a lot about automotive lately, so I thought I’d switch things up a bit and share the success of a medical device mold project attributed mainly to the right CAD/CAM with built-in mold component supplier catalogs.

-

2019 Technology Review: Software

MoldMaking Technology’s July 2019 Technology Review and Sourcing Guide offers some of the latest highlighted products and services from supplier companies from a variety of categories, including software.

-

Vero Software Hires Sales Manager

Vero Software’s Territory Sales Manager, Justin Duke, will oversee sales of the Radan solution for sheet metal.

-

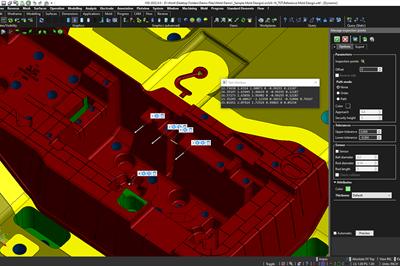

Software Release Enhances Reverse Engineering, Improves Mold Maintenance and Eases Conformal Cooling

The latest release of VISI software includes an extended direct interface to multiple portable measuring arms and scanning devices, ejector pin labeling functionality and advanced sketching of conformal cooling channels.

-

IMTS 2018: Process,Technology and Service Advancements

Advancements in automation and digital manufacturing took center stage during IMTS last week, but developments in additive manufacturing, cutter technology, machining solutions, simulation software, EDM, laser technology and customer service were other hot items.

-

2018 Technology Review and Sourcing Guide: Software

MoldMaking Technology’s annual Technology Review and Sourcing Guide is an accurate, comprehensive, easy-to-read and easy-to-use use guide for researching today’s technology, equipment, products and services. The year’s latest moldmaking product developments within mold engineering/design, build and maintenance/repair are broken down into 10 sections, including software.

-

2018 Leadtime Leader Award Winner: Maximum Mold Group

Strategic acquisitions and diversified capabilities combined with a can-do, inclusive culture take this mold manufacturer to new heights.

-

Hexagon Hosts Vero Software Users' Meeting at HxGN LIVE 2018

Hexagon Manufacturing Intelligence hosts Vero Software Users’ Group meeting, a program designed for users and managers to master best practices, learn new features and realize user benefits. The event takes place June 12–15, 2018 in Las Vegas.

-

Working High End

The right CAD/CAM provides a common language that unites all processes, ensuring that everything moves fluently through the toolroom and across each discipline.

-

Throwback Thursday: Software Advances Push Limits of Speed and Quality

This throwback article provides interesting perspectives on software for moldmaking while also illustrating how fast software technology moves today.

-

Technology Tuesday: Preparing for NPE with Plastics Review

This slideshow has you covered in plastics review with discussion on common plastics problems like sticking and warping. It includes pieces on software analysis for plastic parts, and it even includes a piece on making the most out of used plastic.

-

CAD/CAM Software Has New 2.5-Axis Waveform Strategy for High-Speed Machining

Vero Software’s Visi 2017 R2 has several new and enhanced features, including the 2.5-axis Waveform Strategy that maintains constant tool cutting load.

-

Throwback Thursday: Validating Design Guidelines

Let’s take a look back at how flow simulation software integrated with powerful 3-D CAD functionality can be effectively and efficiently applied to validate guidelines for runner sizing and cooling time.

-

CAD/CAM Allows Moldmaker to Make Big Moves

KA Tooling says its CAD/CAM software provided the necessary confidence to invest in additional CNC machines and move to larger facilities to meet the growing demand for injection molds.

-

Successful, Profitable Mold Design

What to consider when searching for an all-in-one mold design solution.

-

Edgecam Celebrating 30 Years

Edgecam is celebrating its 30th anniversary, and is just as “leading edge” as when the original CAD/CAM system launched in collaboration with Surrey University in the early eighties; and when it changed its name to Edgecam on the same day that Windows 95 was released.

-

Moldmaker Relies on Plastic Injection Analysis System for Perfect Plastic Cover

When a moldmaker received an order for a plastic cover from a company making electrical coupling components, they began the design and manufacturing process using a plastic injection analysis system, which checks mold design and the optimum placement of injection gates.

-

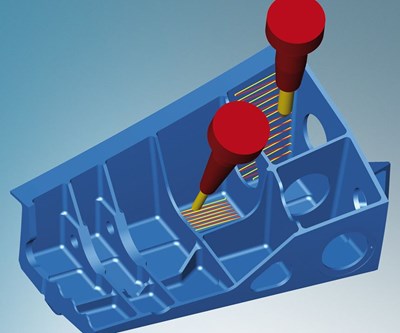

Dedicated Electrode Design Module Revolutionizes Copper Electrode Production

A tooling manufacturer says the combination of a new Sodick EDM AG60L spark eroder and switching to Vero Software’s dedicated electrode design module, VISI Electrode, has completely revolutionized the production of their copper electrodes.

-

Software Advances Push Limits of Speed and Quality

Software for moldmaking continues to evolve as sophisticated features and capabilities are introduced, enabling mold manufacturers to produce the highest quality work in the most compressed leadtimes to date.

-

Taking the Guesswork out of Complex Machining Processes

“Overall, VISI turns a very complicated process such as machining part geometry into a simple process that can be learned quickly.”

-

Plastics Lab Teaches CNC Machining for Core and Cavity Work

As I sit here wearing a Penn State t-shirt, coincidentally I am reading about Penn State Behrend.

-

Vero Strengthens Mold and Plastic Online Presence

New Brand Websites, Twitter Feeds and Corporate Facebook Page

-

Design Collaboration Produces Tooling Right First Time

DeltaCAD Ltd collaborates with sub contract tooling manufacturer Casting Support Systems on a project to provide a leading aerospace company with aluminum tooling for a carbon composite seat shell for a major civil airline company.

-

From the Field: The Right CAD/CAM Makes New Mold Manufacture Easier and the Entire Process More Efficient

Fine, tiny detailing demanded by model railway enthusiasts requires moldmaking tolerances in manufacturing scale models that are often tighter than those in the automotive industry. With the right CAD/CAM system creating the mold around the designed product takes approximately 30% less time than it did with the CAD/CAM system PECO used before switching to VISI.

-

Injection Molding Analysis Ahead of Tool Production Removes Guesswork From Mold Manufacture

Patented injection molding analysis ahead of tool production, ensures that a number of components in a water powered rock drill are manufactured to the degree of absolute precision required by mining operations around the world.

-

Taking Toolpath Creation out of the CAD Office

The VISI suite of CAD/CAM software was instrumental in designing the head configurations, handle and 3-D tooling, along with the CNC toolpaths for a the collapsible shovel.

-

From the Field: CAD/CAM Solution Yields Efficient Tool Design for Micro Electronic Components

Throughout the complete design and manufacturing cycle, the VISI suite of CAD/CAM solutions from Vero Software was used. VISI Progress is used for the design of the components and the punch tool, including the development of the sheet metal component and strip layout. VISI Mold is used for the design of the plastic injection mold. Both modules work together in a seamless construction process.

-

Core 3-D CAM Development and Continued Focus on Tool Design

Vero Software, a leading provider of CAD/CAM/CAE solutions for the tooling industry,offers VISI 19, which represents a substantial release with many new features in all areas of the product.

-

2011 Leadtime Leader Awards: Large Shop Winner

United Tool & Mold, Inc.: Charging Forward with Unique Mold Repair Niche.

-

Software Consolidation Advantages Identified in an Eco-Friendly Milk Dispenser Job

Software aided MNB Moulds when it manufactured tooling for a number of the milk dispenser components including a two-cavity tool for the handle, a two-cavity tool for the lid, a four-cavity tool for the spout spike and an eight-cavity tool for the clamping mechanism for this project.

-

Liquid Silicone Rubber Molding Simulation

LSR and thermoset toolmakers are encouraged to make simulation an integral part of the design process.

-

CAD/CAM/CAE Integration Eases Flow Simulation

Moldmakers benefit from having flow simulation as part of the CAD/CAM environment—reducing the time and effort involved in running a flow analysis study and getting the product to market.

-

Validation of Design Guidelines

Flow simulation software integrated with powerful 3-D CAD functionality can be effectively and efficiently applied to validate guidelines for cooling time and runner sizing.

-

New Design Strategy for Generating Hybrid Aluminum Tooling

Design, machining and analysis software aids in aluminum mold manufacture.

-

New Technology Helps Users Accurately Design Molds

VISI-Flow software helps mold shop determine optimum mold specifications.

-

VISI 5 Axis Machining

VISI 5 Axis routines that provide a complete 5 Axis solution for Mold & Die.The 25 different machining routines come grouped into particular modules dependant on industry allowing you to choose only the functionality you require.

-

Streamlining Processes with The Right CAD/CAM Package

VISI-Series provides the toolmaker a high level of productivity through its specialized applications, and offers dedicated solutions while eliminating the links between varying software suppliers and the solid-to-surface geometry conversions required by traditional systems.

-

Conquering CAD/CAM Challenges

Leading software manufacturers and suppliers reveal how moldmakers can maximize efficiencies using the latest CAD/CAM equipment so they can program and cut complex molds in less time than ever before.