From the Field: CAD/CAM Solution Yields Efficient Tool Design for Micro Electronic Components

Throughout the complete design and manufacturing cycle, the VISI suite of CAD/CAM solutions from Vero Software was used. VISI Progress is used for the design of the components and the punch tool, including the development of the sheet metal component and strip layout. VISI Mold is used for the design of the plastic injection mold. Both modules work together in a seamless construction process.

The area surrounding the city of Pforzheim in Southern Germany is becoming a stronghold for Vero Software and a special kind of tool manufacturer, those working with hybrid materials for high precision, micro parts such as electrical connectors and switches. Among them, Kummer GmbH, with their internally developed K'Tecsystem stands out in particular as an innovator in this unique sector serving the automotive, medical and telecommunication markets.

As far back as 1998, the two company directors Wolfgang and Jens Hofmann recognized that the plastics and stamping industry would become increasingly competitive and invested heavily in R&D and forward-thinking technology. Within two years and after thorough internal testing, Kummer introduced its own sequential laminated injection process, which combines both metal stamping and plastic injection molding within a single machine.

Three Tools in One Machine

With traditional reel-to-reel procedures, stamping and injection machines are connected to each other with regulated loops, as part of a longer assembly line. Using this process, the material is processed in several consecutive steps and the production speed of the entire line depends on the injection cycle, and therefore, the stamping machines have to work at a slower and more uneconomical speed. However, the laminated injection method developed by Kummer (K'Tecsystem), can stamp, bend, form and then also over-mold the processed product with plastic using only one combined machine. This innovative process can manufacture reliable, cost-efficient and high-value components in stamping presses that have a press force range from 25 to 125 tons and a stamping speed of up to 1,000 strokes per minute. The plastic injection machines support all types of thermoplastics with a clamping force of up to 200 tons and shot weights between 1 and 100g.

Development partner Kummer seeks direct contact with customers and offers its full range of knowledge in the field of stamping in order to find an economic solution for each technical problem. When an order comes in, the design engineers start working immediately with the client, offering practical suggestions as to how the design could be modified or optimized, in order to make the best use of the laminated injection process and ultimately make the component more cost-effective to produce.

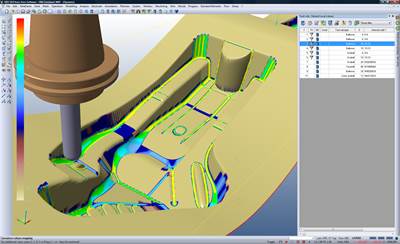

Throughout the complete design and manufacturing cycle, Kummer uses the VISI suite of CAD/CAM solutions from Vero Software. VISI Progress is used for the design of the components and the punch tool, including the development of the sheet metal component and strip layout. VISI Mold is used for the design of the plastic injection mold and both modules work together in a seamless construction process.

“It was important for us to cater to three scenarios using a single 3-D system,” states Thomas Härdt, Head of Development and Construction. "Kummer already had an in-house design system, but found that the system was not efficient for tool design. These systems are fully parametric and so complex, they require 80 percent of your brain power to foresee the best working practice – which leaves only 20 percent for the project itself. With VISI, the opposite is true. The system has proved so easy to use that we were already up and running within two weeks and more efficient than with our previous system after only three months."

Once the tool design is completed, Vero's Compass Technology is used in the CAM department for 2 and 2½-axis CNC programs. The feature recognition is capable of analyzing the 3-D model for regular geometries, such as holes, pockets or T-slots - dramatically reducing programming time and eliminating human error. Based on the standard component type (screw, pillar, dowel etc) feature properties are applied during the tool design phase, which are automatically picked up by Compass.

For example, a hole can be automatically recognized and machined regardless of its diameter, using a different sequence of CAM cycles. “With our previous 2-D system, the feature recognitions rate lay between 80 to 90 percent. With Compass we have already surpassed that mark, and there is still room for further optimization. In total, we are running 16 licenses of VISI Modeling as a base platform and a number of additional licenses for VISI Mold, VISI Progress and VISI Machining with Compass Technology,” explains Härdt.

Using Customer Input for Software Development

Marc Freebrey, Marketing Manager for Vero explains that the Pforzheim area is unique in that there are a highly concentrated number of progressive die companies producing the same type of micro components. "Many of the companies work together to define the CAD standards and the products they use to ensure maximum productivity. Today’s trend is a dedicated CAD/CAM system for mold and die—such as VISI. A customer user group has been established where the users are able to vote on their particular needs and define the priority of items put forward to development. This intimate relationship between customer and software provider ensures the product remains focused on the market requirements and provides the user with an opportunity to help define future developments."

Related Content

Making Mentoring Work | MMT Chat Part 2

Three of the TK Mold and Engineering team in Romeo, Michigan join me for Part 2 of this MMT Chat on mentorship by sharing how the AMBA’s Meet a Mentor Program works, lessons learned (and applied) and the way your shop can join this effort.

Read MoreHow to Solve Hot Runner Challenges When Molding with Bioresins

A review of the considerations and adaptations required to design hot runners and implement highly productive injection molding operations.

Read MoreHow to Use Scientific Maintenance for More Accurate Mold and Part Troubleshooting

Discover how adopting scientific maintenance approaches helps improve mold lifespan, minimize failures, and optimize production outcomes.

Read MoreHands-on Workshop Teaches Mold Maintenance Process

Intensive workshop teaches the process of mold maintenance to help put an end to the firefighting culture of many toolrooms.

Read MoreRead Next

Core 3-D CAM Development and Continued Focus on Tool Design

Vero Software, a leading provider of CAD/CAM/CAE solutions for the tooling industry,offers VISI 19, which represents a substantial release with many new features in all areas of the product.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More