Enhanced CAD/CAM Software Optimizes User Experience and Design Process Speed

VISI 2022.0 from Hexagon offers CAD and CAM updates from optimized and new commands, 30-60% 3D roughing operation calculations and easier file transfer between versions.

Photo Credit: Hexagon Manufacturing Intelligence

Hexagon Manufacturing Intelligence announces significant developments in CAD/CAM functionality of its latest VISI 2022.0 software release. Distributed and supported in North America by TST Tooling Software Technology, the software is said to give users additional speed and quality throughout their design and machining process.

CAD updates in VISI 2022.0 focus on the user experience and add enhancements to enable customers to speed up their design process.

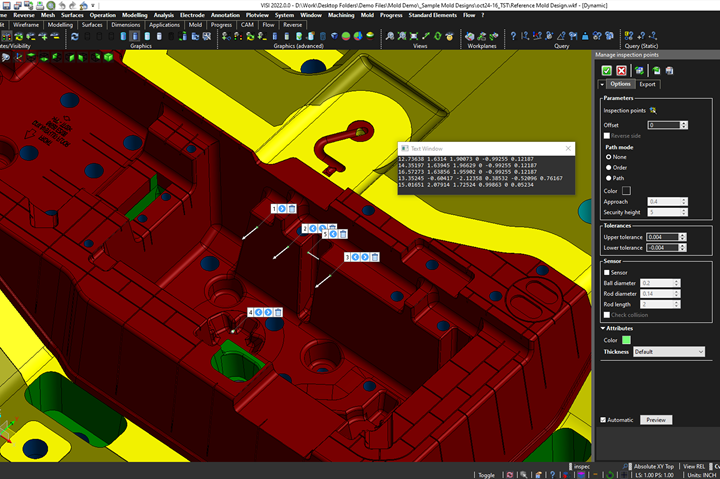

The Solid Interference command, for example, has been optimized for easier identification of solid interferences. The new Inspection Points Management command allows the user to create a pointset for CMM inspection, edit it, visualize/edit the order and path. Further, it offers collision protection and CSV export. Flow, a new calculation engine supports a robust mesh independence and enhanced flow front-freezing estimation. The tool cavities feature now adds the possibility to automatically add a blend as an option on detected corners; this function has been added to simplify the manufacturability of these plates.

For VISI’s CAM functionalities, Hexagon says an angular tolerance option has been introduced for better mesh quality control, providing improving surface finish conditions for users performing micro machining or focusing on smaller electrodes with tight ribs. The roughing strategy has further been improved to speed up calculations.

Hexagon also notes that speeds with 3D roughing operation calculations are between 30-60% faster than in previous versions. This is based off provided files examples from internal and customer provided data.

It is also now possible to transfer wire post configurations from the previous 2021.0 version to VISI 2022.0 using the standard migration tool. The user can run the migration tool which will transfer all the files necessary to make these configurations read automatically in VISI 2022.0. It transfers the customizations done on default machines and on duplicated machines.

Related Content

-

How to Improve Your Current Efficiency Rate

An alternative approach to taking on more EDM-intensive work when technology and personnel investment is not an option.

-

Tolerancing in Mold Design, Part 2: Using GD&T to Address Conventional Tolerancing Issues

Mold designers can achieve a single interpretation of workpiece functionality when following the American Society of Mechanical Engineers Geometric Dimensioning and Tolerancing standard.

-

Four Micro Tooling Considerations

Issues involving gating, ejection, mold splits and direction of pull are of special concern when it comes to micro tooling.