Successful, Profitable Mold Design

What to consider when searching for an all-in-one mold design solution.

CAD/CAM: Core and Cavity Cutting

It is a common thread among today’s mold engineers that mold design software isn’t as user-friendly as it should be. There seems to be a wish list of ideal components that a “perfect” mold program should possess to help moldmakers face their mold design challenges head on.

The largest problem mold shops are facing today is the confusing proliferation of CAD/CAM software types, all of which don’t function as a cohesive whole. There could be up to as many as 10 different types of software in one shop alone. With so many different software languages running at the same time, it is no wonder that shops must deal daily with increased production lag time along with troubleshooting and a flawed final product. If engineers could gather the basic tools needed to build a successful, profitable part in a fraction of the time, most—if not all—of the inherent software problems infiltrating

today’s shop floor could be solved.

Some basic tools needed for successful mold design are not without their flaws. A few of these shortcomings seem to be a recurring theme among frustrated designers. The struggle of dealing with a wide variety of file types while trying to maintain design accuracy is an everyday reality. While at the same time software that lacks a built-in plastic flow analysis option, which would provide basic fill and pack scenarios, would solve the issue of dealing with non-functional plastic parts.

Completely customizable component libraries and mold design process builders are also tools that are missing in the design process.

These fundamental utilities would give the designer a huge competitive advantage while not succumbing to the typical CAD software. Having access to parametrics, when it makes sense as well as to a constantly updated library with the latest components and part numbers, would not only save time in the design process, but would also greatly improve product turnaround time.

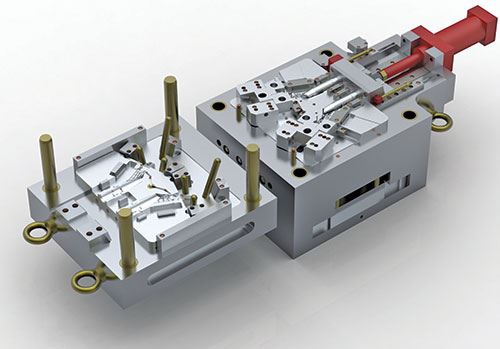

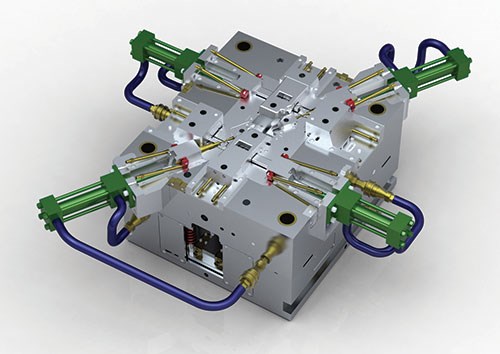

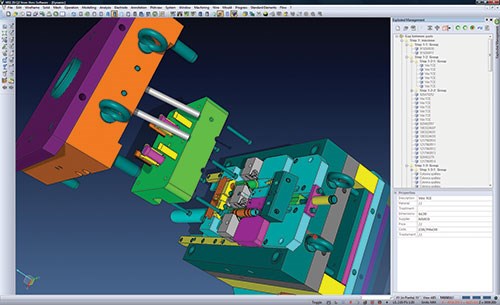

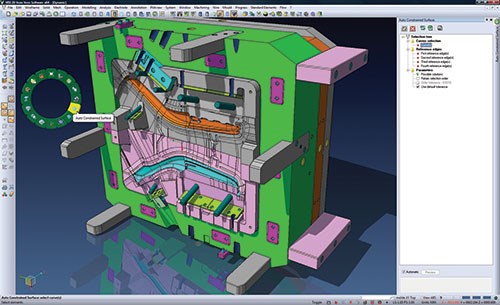

Another area that remains challenging to designers is the organization of geometry within the design system. The use of colors to separate and organize shut off areas, clearance areas, part shape and water lines enables shop personnel to easily identify what is critical and what is not.

Mold software should not be limited to design only. It should easily flow through the various shop departments—meaning it should contain tip information, shrink values, electrode information, critical attributes, BOM and machining with the ability for 2D and 3D, and full 5-axis capabilities.

A true software solution would also have the ability to easily analyze and modify supplied part data, modify part draft and add windage. Then be able to send part data back to the customer in their native format. The software should also have multiple viewers throughout the shop, which saves time, reduces distractions and costly prints—without any hang-ups along the way. This would prove to be advantageous not only to the designer and shop floor, but to the company as well. The improved production speed and part quality not only give a better finish on the product, but more accurate tooling means that the manufacturer’s timescale is reduced, along with the number of set-ups producing cost-effective runs each and every time.

Summary

While researching specifics for a mold software solution for your shop make sure it is customizable to your design and manufacturing needs. Keep in mind universal file types, part changes, flow analysis, component libraries, quick and seamless translation to the shop floor and availability in one software package. The package should be both affordable and powerful enough to keep up with today’s manufacturing demand and increasing the shop’s bottom line, while keeping engineers productive and designs error-free. Remember too, that available first-class software support to answer questions or troubleshoot problems whenever they arise is critical to software success. With the right software you can be assured your shop can achieve its goals and increase its bottom line.

Related Content

Tips for Tackling Mold Design, Machining, Cutting Tool and Wear Challenges

Tips for tasks ranging from reducing risk in part design and taking advantage of five-axis machining to refining cutting tool performance and reducing wear with guiding and centering systems.

Read MoreWhat Is Scientific Maintenance? Part 1

Part one of this three-part series explains how to create a scientific maintenance plan based on a toolroom’s current data collection and usage.

Read MoreThree Good Reasons to Switch from Three- to Five-Axis Machining in Moldmaking

Five-axis machining technology is a great tool in the moldmaker toolbox.

Read MoreHow to Select a Mold Temperature Controller

White paper shares how cooling channel analysis, which collects maximum pressure drop, total flow rate and heat dissipation, eases the performance evaluation of mold temperature controllers.

Read MoreRead Next

Streamlining Processes with The Right CAD/CAM Package

VISI-Series provides the toolmaker a high level of productivity through its specialized applications, and offers dedicated solutions while eliminating the links between varying software suppliers and the solid-to-surface geometry conversions required by traditional systems.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More

.jpg;maxWidth=300;quality=90)