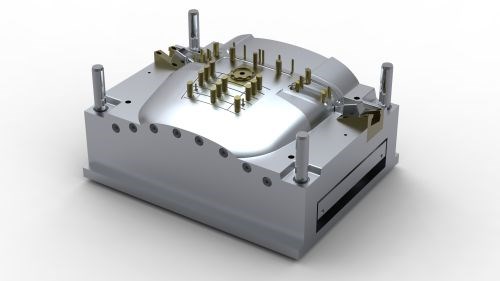

CAD/CAM Allows Moldmaker to Make Big Moves

KA Tooling says its CAD/CAM software provided the necessary confidence to invest in additional CNC machines and move to larger facilities to meet the growing demand for injection molds.

Related Content

-

CAM Automation Increases Mold Production, Quality

Mold builder switches CAM software package after 20 years to take advantage of innovative programming strategies that reduce mold machining programming and processing times.

-

How to Harness 3D Scanning for Mold Tool Repairs

3D scanning supports the repair of molds with no history, drawings or design files.

-

Five-Axis Vertical Mill Increases Mold Shop Capacity by Reducing Setups

Zero Tolerance now processes blocks — from squaring to waterline drilling to rough and finish milling — on a single five-axis CNC mill, reducing setups and moving blocks in/out of multiple machines without sacrificing accuracy and surface finish.