Streamlining Processes with The Right CAD/CAM Package

VISI-Series provides the toolmaker a high level of productivity through its specialized applications, and offers dedicated solutions while eliminating the links between varying software suppliers and the solid-to-surface geometry conversions required by traditional systems.

H.S. Die and Engineering was born in a garage and today it is the largest moldmaker in the U.S. and second largest in Norh America thanks to Owner Harold Steele.

It all started in 1969 and today its headquarters are located in Grand Rapids, MI. H.S. Die serves the automotive and consumer products markets and its customers include Lear, Intier, Collins & Aikman, Deere, Toyota, Ford, General Motors, Chrysler, Nissan, Mitsubishi, and others. In 2002, the company won the Supplier of the Year for outstanding performance from Intier Automotive.

Headquarters and Plant #1 house the company’s design team of approximately 25 designers who use multiple seats of VISI CAD/CAM software products from Vero International (Bingham Farms, MI).

Using the Right Design and Manufacturing Solution

VISI-Series is a PC-based design and manufacturing solution for the mold and die industries. It offers a unique combination of applications, fully integrated wire-frame, surface and solid modeling, comprehensive 2-D and 3-D machining strategies with high-speed routines and dedicated tool design for plastic injection and progressive dies.

A Change in Design

Phil Tanis is H.S. Die’s design supervisor, and aside from his normal responsibilities, he and his team conduct feasibility studies to determine if designs are moldable, and review all work prior to sending it to manufacturing. He was one of the first H.S. Die employees to use VISI software when it was implemented four years ago.

Tanis says the most important customer requirements are time and money. “They work hand-in-hand,” he notes. “Besides that, we focus heavily on service. We want to help the customer make sure they will build a tool that will operate flawlessly. Our goal is to protect the plant.” He says that a big part of achieving that goal is the use of VISI tools.

Prior to implementing VISI, Tanis and his team of designers used disparate software products that didn’t talk to each other. Company owner Steele’s philosophy includes constant improvement in all segments of the organization. “The installation of VISI dramatically helped us change the way we design and manufacture products,” adds Tanis. “Using the software allows us to streamline processes. As a result, we are a completely paperless environment—from the design arena to the machining floor. Everyone shares the same 3-D models and speaks the same language because everyone is trained to use VISI, including designers, moldmakers, machinists, sales people and program managers.”

Allegiance to Product Viability

With the plethora of CAD tools on the market, Tanis says he and his team tested several commercial software products prior to selecting VISI-Series. “We opted for VISI because, like most products, the software is easy to use. But more importantly, Vero goes the extra mile by providing on-site assistance, ongoing training and continuous support. Since we started working together, Vero has listened to us and implemented many enhancements to the software with each release,” says Tanis.

Owner Steele notes, “One of the most important reasons why we selected VISI-Series is the ability to customize the software to meet our specific needs. Vero’s organization is flexible to quickly respond to our needs. The VISI/Vero team is one of cooperative, open-minded, and creative individuals who work very well together to help our operations work faster and more proficiently. This type of relationship is uncommon between software user and software provider.”

As testimony to Vero’s commitment to the H.S. Die applications, Jim Kesteloot, principal of TST Software, a Vero distributor in Michigan, has an office at H.S. Die’s Grand Rapids operations. He spends at least one day per week on-site.

“This ongoing support isn’t unique to H.S. Die. We offer the same type of service to all our customers. No other CAD/CAM provider can attest to this allegiance to product viability helping customers achieve success like H.S. Die has enjoyed over the years,” explains Kesteloot.

Unrestricted Use

Kesteloot says, “VISI is different from other CAD/CAM packages because it is not restricted with a typical program tree. VISI users can work in solids, surfaces and wireframes without being locked to a tree configuration. The flexibility of the modeler allows designers to work in any mode.”

Tanis says that using VISI 3-D models allows his designers to show customers everything they need to know. “They can see the tool as a finished model including a computer visualization of the physical mold in a press with all components taken into consideration. This capability is very powerful and assures customers that the mold will operate as designed,” Tanis adds.

The busy design team cranks out more than 500 tools per year. Tanis says that working in a 3-D mode allows his designers to be more productive and thereby, address more work. In order to accomplish that, he set up teams of assignments for each job including design, mechanical work, water injection and tool build up, and checking models before they are sent to the machine shop.

Improved Surfacing Tasks

H.S. Die CAD/CAM System Manager Dave Scramlin schedules the surfacing of all tools and coordinates the work for the shop floor. He is the liaison between surfacing and manufacturing. Almost all the people working under Scramlin are journeymen toolmakers.

“They know how to build a tool and what to look for in terms of tool manufacturability,” Scramlin says. His team uses VISI to complete the 3-D models with mold details, such as radii, parting line relief, vents and other important details to make sure the tool is a viable model for cutting.

He says their work is challenging and interactive with the shop floor. “We strive to obtain a good, clean model. VISI software provides us with the tools that allow us to be more proficient and speed up our productivity,” says Scramlin.

Going to the Next Level of Expertise

Scramlin and Tanis note that H.S. Die has a close relationship with Vero. “From where we were before implementing VISI to where we are today, we have been able to add intelligence to our models. That capability alone,” Scramlin explains, “has taken us to the next level of expertise. The software and our use of it have helped us become more competitive and remain profitable.”

Steele, who remains the sole owner of the corporation today, cites the company’s success is due in large part to his active involvement and investments in new technologies and commitment to the manufacture of world-class tooling.

“Over the years and to this day,” notes Steele, “I’ve stayed close to the business working with the staff because I’m always looking for innovation and change. I call myself the Idea Man. I provide the ideas and try to instill incentives to nurture the idea to fruition. The results of the incentives result in a better future for my employees and their families. It’s easy to become complacent. That’s not for me. I get up everyday and say, ‘I’m going to learn something new today.’”

As for ideal H.S. Die employees, Steele says he looks for individuals who are creative, ambitious, and who show common sense. “As a result, I’ve been able to build very talented teams who have collectively helped to successfully grow the business to what it is today.”

For more information contact Vero International at www.veroint.com, H.S. Die at www.hsdie.com or TST Software (the distributor cited in this article) at www.tst-software.com, or e-mail the author at lcarrabine@earthlink.net.

Related Content

How to Select a Mold Temperature Controller

White paper shares how cooling channel analysis, which collects maximum pressure drop, total flow rate and heat dissipation, eases the performance evaluation of mold temperature controllers.

Read MoreWhat Is Scientific Maintenance? Part 1

Part one of this three-part series explains how to create a scientific maintenance plan based on a toolroom’s current data collection and usage.

Read MoreVIDEO: Perspective on A.I. and Mold Design

Bill Genc of TopSolid shares his perspective on the benefits of and barriers to using artificial intelligence in mold design.

Read MoreTolerancing in Mold Design, Part 2: Using GD&T to Address Conventional Tolerancing Issues

Mold designers can achieve a single interpretation of workpiece functionality when following the American Society of Mechanical Engineers Geometric Dimensioning and Tolerancing standard.

Read MoreRead Next

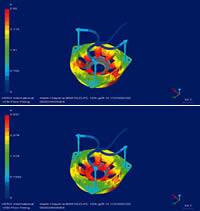

New Technology Helps Users Accurately Design Molds

VISI-Flow software helps mold shop determine optimum mold specifications.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreAre You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More