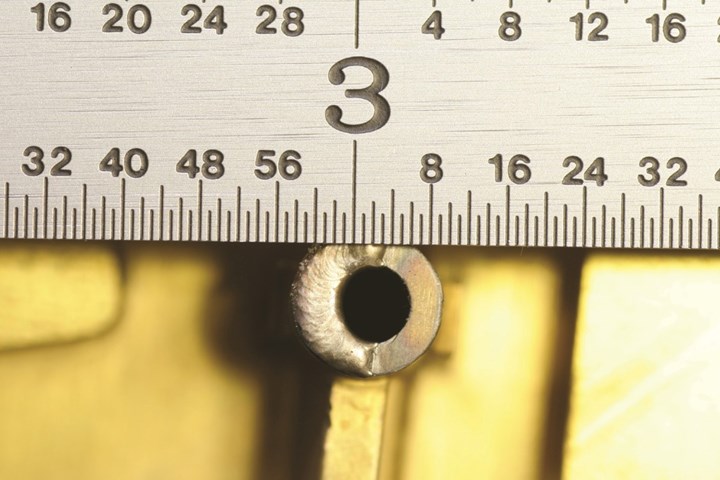

The micro welding process by FiveStar Toolwelding of Butler, Wisconsin. Photo Credit: Miller Electric Mfg

For as long as there have been molds, there has been the need for tool welding. This is to repair or restore components for molds, as well as restore surfaces machined or worn out of specification. The exact reasons for using the welding process is to eliminate fabrication of a new part or parts affected by engineering changes, wear, water leaks, damage from equipment malfunction or even an occasional metallurgical defect. Welding is also the option most often used to reduce cost and reduce lost time when compared to making new mold components.

Micro Welding

Micro welding is the name given to the process that has evolved from traditional TIG welding (or more recently termed GTAW), using the technology of electric current being applied to the workpiece to generate heat at the point of the arc gap. At the point of the arc gap, a molten pool is established and the filler rod is introduced into the molten pool.

The difference between traditional TIG and micro welding is that micro welding is done at extremely low amperages (usually less than 10 amps) in combination with fine control of the amperage range, along with the aid of a high-powered (10-20 times or more) microscope. In the micro welding process, the technician performing the weld repair — in combination with the welding equipment controls and the weld wire selection — is absolutely critical to end results.

Laser Welding

Laser welding — on the other hand — uses light energy to rapidly heat the weld zone, melting the filler rod along with the adjacent point of metal joining. The light energy intensity is controlled by beam size, voltage and pulse width, singularly or repeated at variably timed intervals. Because an independent high intensity light source is used, no current flows through the workpiece. There are no electrical connections or current polarity effects to the weld or to the workpiece with laser welding.

With the laser process, there is no heat generated in the workpiece by electrical current flow or resistance to flow. Because the laser beam is used to melt the base material and the filler rod, the process becomes a line of sight as well as focal point limited process. This means if you cannot get a straight shot with the laser beam to the weld zone or cannot position the weld zone at the correct focal point of the laser power, the process will not work efficiently or correctly. Microscopic magnification, similar to micro welding, also is used in the laser welding process.

Filler Rod Choices

Filler rod, or more appropriately termed wire, is small for both laser and micro welding. Wire sizes on the small side begin at .003 inch ranging up to .025 inch, usually in increments of .002 or .005 as the diameter increases over .015 inch.

Filler wire is available in most common tool steel and mold steel equivalents. There are copper alloys available for application on both copper nickel and beryllium copper alloys in the small sizes of filler wire, and of course, aluminum wire is available too.

In choosing a wire to use on tool steel, stainless grades of wire seem to show the most overwhelming success and compatibility. When applying a tool steel wire to a tool steel base, there can be the occasional issue relating to adhesion and contamination when using either the laser or micro weld process.

Other Notable Differences

At this time, laser welding equipment is extremely expensive when compared to micro welding equipment. Also, welding technicians experienced with the TIG process can have difficulty adapting to the difference in how the filler wire is used in the laser welding process.

Generally in laser welding, the filler wire is melted onto the workpiece with the heat of the light beam where the wire and workpiece are melted simultaneously. In the TIG process, the filler wire is melted by the introduction of the wire to the molten pool created by the arc gap.

Shielding gases are common to both laser and micro welding processes, although shielding gases are less critical in laser welding. Small repairs using the laser process with aluminum have shown superior results when compared to TIG. Most notable with laser welding is that the overall temperature of the workpiece rarely gets warmer than what can be held in your bare hand.

Summary

Both the laser and micro weld processes have positive and negative issues. Promoters of the laser welding process claim that dimensional and shape distortion are nonexistent with the laser process, yet during usage of the laser process, there has been an occasional change to both dimension and shape, which at each occurrence was unexpected. All appeared as cases that were completely unpredictable.

On the other hand, micro welding repairs — although not the rule — can still exhibit sink areas, fractures, separation of weld and other incidents occasional to the TIG welding process.

One thing is certain: both laser and micro welding processes are improvements to traditional TIG tool welding, and both processes have definite benefits and expanded opportunities for applications. The tool welding shop of the not too distant future will need to offer conventional TIG, micro welding and laser welding services to completely fulfill the tool welding requirements of its customers.

Related Content

What You Need to Know About Hot Runner Systems and How to Optimize Their Performance

How to make the most out of the hot runner design, function and performance.

Read MoreWhat Is Scientific Maintenance? Part 1

Part one of this three-part series explains how to create a scientific maintenance plan based on a toolroom’s current data collection and usage.

Read MoreWhat is Scientific Maintenance? Part 2

Part two of this three-part series explains specific data that toolrooms must collect, analyze and use to truly advance to a scientific maintenance culture where you can measure real data and drive decisions.

Read MoreQuestions and Considerations Before Sending Your Mold Out for Service

Communication is essential for proper polishing, hot runner manifold cleaning, mold repair, laser engraving and laser welding services.

Read MoreRead Next

The Value of a Shop’s Welding Policy

To put the appropriate welding policy in place, you need to choose the right welder—someone who is familiar with tool steel and has a working knowledge of molds.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More