Tips

Requirements for Automated DFM for Injection Molding

Designing for injection molding can be a complex process, but combining automated design for manufacturability tools with technical guidance streamlines the workflow and minimizes costly delays.

Read MoreStreamlining Mold Assembly With Pre-Cut Pins

Incorporating pre-cut ejector and core pins into your moldmaking process can improve efficiency and reliability.

Read MoreHow to Polish Ribs for Proper Part Release

Using the right tools and abrasives is essential to polish a mold to the required final finish.

Read MoreThree Good Reasons to Switch from Three- to Five-Axis Machining in Moldmaking

Five-axis machining technology is a great tool in the moldmaker toolbox.

Read More7 Things You Need to Know About Nearshore Opportunities

Essential tools and resources to support mold builders in making critical strategic decisions about doing business in Mexico.

Read MoreFour Micro Tooling Considerations

Issues involving gating, ejection, mold splits and direction of pull are of special concern when it comes to micro tooling.

Read More5 Ways to Improve Supply Chain Visibility and Efficiency

Mold builders play an important role in creating smart, connected and transparent supply chains.

Read More4 Cutting Tool Challenges and Solutions

A combination of cutting tool carbide, coating and geometry helps tackle four mold machining challenges and improve cutting performance.

Read MoreHow to Overcome Complex Mold Texturing Problems

Key benefits when considering laser technology for mold texturing and repair.

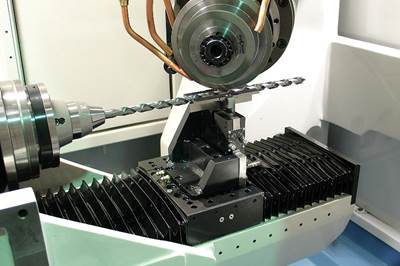

Read MoreHow to Overcome Common Deep-Hole Drilling Challenges

Producing deep holes effectively and efficiently is a challenging application that requires cutting tool solutions that offer predictable cutter life, accurate surface finish and repeatability.

Read More