MMT Blog

Wear Parts and Consumables: The Keys to Maximizing Your EDM

Mold shops need to pay attention to the potential impact wear parts and consumables can have on their overall production.

Read MoreOve Nielsen: A Standing Ovation!

This SPI Moldmaker of the Year 2005 honoree’s diligent work for the industry has spanned two continents.

Read MoreSo You Think You Know Your Molds?

Keeping molds production ready and reliable is much more dependent upon proactive maintenance measures than reactive habits.

Read MoreMaintaining a Strong Relationship with Your Hot Runner Supplier

Once your hot runner supplier is chosen, you need to take the proper steps to maintain a mutually beneficial, long-term relationship.

Read MoreUp Close and Personal

Getting up close and personal with the latest current and emerging technologies affecting the mold industry is the best way for mold manufacturers not only to see what is out there.

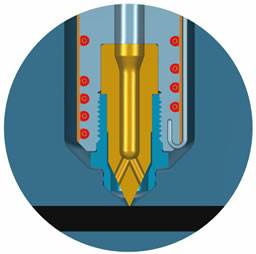

Read MoreSelecting the Right Gating Method for Your Application

Designers may select among four hot runner gating methods, each with its advantages and disadvantages.

Read MoreHow to Choose the Right Tool Coating for Your Machining Application

Selection criteria and common coating attributes for PVD, CVD and other common coatings.

Read MoreNew Business Model Required For Mold Manufacturers

Annual study shows changes in the moldmaking industry and provides insight to help make the right decisions for your shop.

Read MorePart Two of a Three-Part Series Five Steps for Improving Your Shop’s Maximum Productivity Part 2

The reasons and justification behind moving your component finishing operation from EDM sinking to hard milling with the right machine, software, cutters, toolholders and training; and how you can add machine time to your shop through lights out machining.

Read MoreDefining the Data Barrier, Part 3: Utilizing data to set goals

Using data as your compass will allow you to head off issues before they become issues.

Read MoreSimulate and Optimize Your Mold Build Process

Mold shops can increase efficiency, lengthen tool and machine life and achieve better surface finish with the same software they use to verify their increasingly complex NC programs.

Read MorePart One of a Three-Part Series Five Steps for Improving Your Shop’s Maximum Productivity

Learn how to evaluate your shop’s productivity and begin increasing it by considering the variables of implementing hard milling and high-speed machining.

Read More