MMT Blog

Breaking the H-13 Stereotype For the Common Mold

A look at the new grades and steel making practices that are available to address the day-to-day issues that occur in the operation of a mold.

Read MoreThe Value of a Shop’s Welding Policy

To put the appropriate welding policy in place, you need to choose the right welder—someone who is familiar with tool steel and has a working knowledge of molds.

Read MoreJustification Through Data

Including position analysis in your data collection practices will help you make smarter maintenance and mold design decisions.

Read MoreOpportunities for Mold Shops with Micro Molds and Micro Milling

Learning about the trends and challenges with micro molds and micro milling will help shops maintain their competitive edge.

Read MoreMaking the Most of High-Performance Mold Materials

Understanding high conductivity alloys and optimizing their use can help you build better molds.

Read MoreHow to Avoid the Pitfalls of Overseas Partnerships

Having the knowledge of the potential pitfalls will help to ensure the success of your overseas outsourcing.

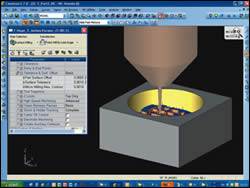

Read MoreThe Keys to Successful High-Speed Machining

Moldmakers will reap all the benefits of high-speed machining with the right mix of machine tool, tooling and programming.

Read MoreMold Building Without Rule Breaking

Push the mold in the beginning of the build process to discover any weaknesses before it gets to the molder.

Read MoreUncovering New Market Potential

A moldmaking enterprise can help develop new and potential markets, create work and remedy our battered economy by being open to new markets of opportunity.

Read MoreThree Influences that Are Critical to Mold Performance

Analysis, integrated design and value-engineering play an important role in choosing the right hot runner supplier.

Read More