Early Collaboration, Part Design Involvement Key to Global Growth in Packaging

This mold manufacturer has achieved success by partnering with manufacturers in the packaging and closure markets on innovative plastic part designs—not simply providing a mold quote.

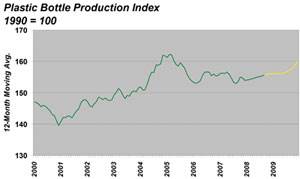

The packaging industry is usually considered a stable market in the mold manufacturing industry due to the fact that eating is a necessity. Trends include the continued “light-weighting” of plastics products in response to brand owners wanting to “refresh” their current products while keeping them safe and easy to use for consumers.

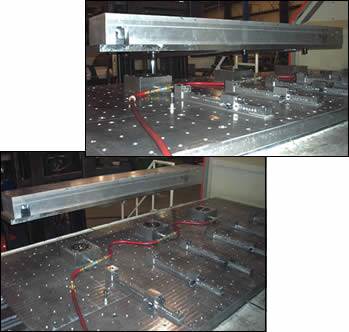

Moldmakers such as StackTeck (Brampton, ON)—specializing in multi-level stack molds as well as single-face molds for thinwall packaging, caps and closures, medical and personal care industries—have found success in this market by not only developing innovative technologies to service the market from a mold manufacturing perspective, but also bringing to the market innovative plastic part design ideas and sometimes partnering with packaging designers, particularly for high volume beverage closure applications. By partnering with these companies, StackTeck is able to offer its customers complete solutions instead of simply building a mold.

Packaging Trends

Light-weighting

According to StackTeck General Sales Manager Jordan Robertson, “In conjunction with the light-weighting trend, we are seeing high index melt resins being used, more attention being paid to the plastic part design of the parts, and an increased demand for a precisely engineered and manufactured tool. As the plastic gets thinner and thinner, it becomes more critical that the core and cavity alignment is optimal from the get-go and stays aligned during the injection molding process.

“You need the highest technology in molds available, and increasingly high performance machines that are available with fast and precise injection capabilities,” he adds.

StackTeck VP of Business Development Michael Gould expands on Robertson’s thoughts. “Some additional factors that are helping drive the light-weighing effort are a drive by brand owners and packaging companies to refresh their image. A lot of that is centered around three critical factors: consumer product safety (e. g. tamper evidence packaging), brand product safety (the package needs integrity and protect product during shipping so it doesn’t arrive damaged); and ease and convenience of use (e.g. a possibly reusable container or at least reusable for the life of the product inside). These three things are taken into consideration when a refresh or relaunch of a product line is occurring.”

Both Robertson and Gould see a trend toward building high output molds to effectively compete in this market, as the injection molding industry faces competition from thermoform packaging. At the same time, there is an increase in niche/specialty packaging that is targeted by product. This is where building family or stack tooling can provide a solution to both scenarios. “About half the molds we build are single face molds. In regards to stack molds, in some cases we could go with a single-face tool that can easily convert to a stack tool—whether it be a two-, three- or four-level—depending on the growth opportunity that customer has. It gives them a new option to grow with the market instead of having to make a significant investment up front,” Robertson notes. “And with family stack molds, our customers want the economics of the stack mold, but don’t have the volume to fill up both faces of a two-level stack mold. A family stack mold has the first product coming out of the first face and a second product coming out of the second face.”

Whether it’s for single face or stack molds, StackTeck reports increasing use of Quick Product Change (QPC) mold designs that enable molders to switch production from one product to another with a typical changeover time of 30-60 minutes for injection molding systems up to 1100 tons in size.

A Steady Future

Robertson maintains that the packaging industry will continue to be a lucrative market for mold manufacturers. “In addition to the fact that packaging is a stable market, packaging also is a significant opportunity for the brand owners out there to enhance the value of their offering at a very moderate investment.”

Gould adds that the key to StackTeck’s success in this market is two-fold. “We are always coming up with new technologies (full details at moldmakingtechnology.com/1109end.html) to service the market as a mold manufacturer,” he states. “We also bring to the table a host of innovative plastic part design ideas—partnering with companies that specialize in packaging design to help enable them to come out with new creative designs in plastic. For example, we have joined forces with Universal Closures (UK) to produce both standardized and custom-designed closures. In the case of high volume, 1881 tamper evident beverage caps, we have worked together to design, prototype and qualify the cap with major brand owners—enabling molders to switch from older, heavier caps that require liners, to a new, lighter, linerless design without time or cost for design, prototyping or qualification (there is a license fee).

“Collaborations like this grow our business and allows us to be a solutions provider, not just someone quoting a mold,” Gould concludes. “Getting involved very early in the process with upfront development work, prototyping, and truly developing a product with our client and then rolling it out into production tooling, is the future in this market.”

Related Content

R&D Drives Innovation and Problem-Solving at Michigan Blow Mold Builder

Mid-America Machining focuses on reshaping designs, “right weight" initiatives, continuous improvement and process refinement to enhance moldmaking efficiency.

Read MoreHow to Solve Hot Runner Challenges When Molding with Bioresins

A review of the considerations and adaptations required to design hot runners and implement highly productive injection molding operations.

Read MoreMMT Chats: Digitalizing Mold Lifecycle and Process Performance

MMT catches up with Editorial Advisory Board member Bob VanCoillie senior manager of Kenvue’s mold management center of excellence outside of Philadelphia to discuss mold management via tooling digitalization and OEM expectations and opportunities.

Read MoreWhat is Driving Mold Lifecycle Management Digitalization?

OEMs are looking to partner with suppliers to share and track data across the supply chain for advanced intervention and process management.

Read MoreRead Next

Sustainability Raises the Stakes for Mold Performance

OEM demands for lightweight packaging are creating design challenges for toolmakers.

Read MoreStackTeck Systems Ltd.: Continuous Improvement Trims Leadtimes

This moldmaker’s maturing outlook on operations processing and scheduling, combined with continuous improvement initiatives, results in overall leadtime improvement of 15 percent and garners them the MoldMaking Technology 2008 Leadtime Leader Honorable Mention: Large Shop.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read More