Polishing: Trends and Opportunities

Polishing industry trends “mirror” those in the moldmaking industry: shorter leadtimes, new growth opportunities/diversification and process improvement via technology advances.

In the world of polishing, current trends are mirroring industry trends: overseas competition, shorter leadtimes and high-speed machining technology decreasing the need for handwork and finishing. Below are five trends and opportunities in this market.

1. Overseas Competition and Business Opportunities

Unfortunately, the polishing industry has also suffered due to a majority of mold build work moving overseas, according to Dave LaGrow, vice president of M&M Polishing (Coloma, MI)—a provider of benching and polishing services. “We are all getting hit by overseas competition and it’s taken a big chunk of manufacturing work out of the states,” he notes.

However, the poor quality of molds that are built overseas is bringing polishing work back to North America, according to Betsi Burns, Sales and Product Manager, Polishing Products for BORIDE Engineered Abrasives (Traverse City, MI)—an abrasives (polishing stones) manufacturer. She notes that since mold building has shifted overseas, the quality is not there. “The molds typically don’t have long to run before they need repair,” Burns says. “This can result in the need for more polishing.”

This overseas shift has led to mold manufacturers diversifying into other markets, which has had a surprising side effect for LaGrow. “Some of our customers are branching out into aerospace and military work,” he comments. “At first I believed that this would not be good for me because I thought, ‘My mold polishing customer is now going into aerospace instead of what he is currently sending me.’ But, it turns out that a lot of this work in the aerospace industry requires mold benching and polishing. We’ve had helicopter parts in our shop that we’ve had to bench and polish. And, we’ve had to send our polishers to places where the molds are too big to polish them.”

2. New Automotive Projects Open Doors to Mold Polishing Work

According to Rob Esling, Sales and Marketing Manager for mold and tool steels at Industeel USA LLC (Coatesville, PA,)—a specialty tool steel supplier—major automobile manufacturers like GM are in the midst of a major restructuring of their product lineups revamping current models. “The timing demands in this industry are much more stringent now than they have ever been because everyone wants to get their products to market faster,” Esling states. “A moldmaker would pay an in-house polisher overtime for any night/weekend work that would arise from these faster turnaround times.” Esling adds that moldmakers may want to consider sending the polishing work out to specialty shops during times of high demand.

3. Polishing Processes Affected by Decreasing Leadtimes

In response to the trend for shorter leadtimes, M&M’s LaGrow has placed multiple people on jobs and has developed a system that is more like a production line. “Different people specialize in different areas of mold polishing,” he explains. “We also work around the clock, seven days a week, to help people with shortening their leadtimes. Interestingly enough, I had a customer tell me he would use us strictly because one of my main competitors is a little farther away, and if he can save 10 hours of transit and I can match the price, he would send it to me. That says a lot about shortening leadtimes and what our customers are up against.”

4. High-Speed Machining Advances Change Polishing Demands

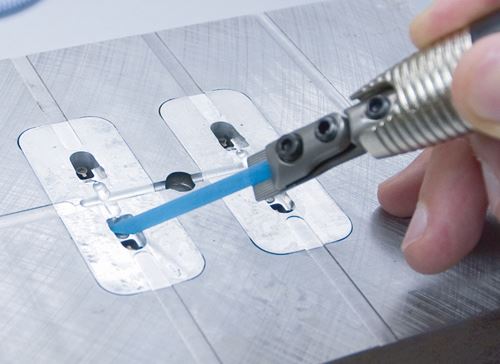

According to Darcy King, president of Unique Tool & Gauge, Inc. (Windsor, ON)—πa moldmaker who specializes in aluminum tooling—the advent of faster, higher tolerance machines produce a much better finish on tools. “The better finish you have, the less time you need for handwork,” King points out. “This has changed considerably over the years and continues to change as the technology gets even better. It allows you to skip a couple of steps when it comes to polishing and save time on your overall polishing. We see this both with polishing of aluminum and steel.”

“Polishing will never go away, there will always be a need for some form of polishing on molds,” Burns adds. “If you take a look in your home, office, or car—every plastic part from your stereo equipment housing to your cell phone, to the parts on your vehicle’s dashboard—comes from a mold that needed to be polished. But the finishes are getting a lot better coming right out of the machine, which means less handwork.”

5. Mirror Finish Requirements Accelerate Polishing Need

The prevalence of electronic devices like PDAs and cell phones that require mirror finishes has had a positive impact on the polishing market. “Notice that the plastic housing of a cell phone usually has a pretty high polish,” BORIDE’s Burns comments. “You can see yourself in the plastic. As more products like this are designed and manufactured, the need for finer finishes is obviously greater. There are many different products that are used on a daily basis requiring a diamond or mirror finish so the end product is aesthetically pleasing to a consumer. Before I worked in this industry, I never paid attention to different plastic products, but now I notice when a cosmetic case, soda bottle or even safety glasses have come from a mold that was at a mirror finish. People inherently like products that are pleasing to the eye and companies like containers that make their product show well.”

Summary

Both the growth in aluminum molds and use of specialty steels in molds benefit the polishing market because these materials offer advantages like improved cycle time, improved throughput, and overall quality as it relates to polishing. At the end of the day, it is all about how one can improve piece part cost and get product to market faster.

Read Next

Are You a Moldmaker Considering 3D Printing? Consider the 3D Printing Workshop at NPE2024

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More