MMT Blog

Capacity Utilization Rate Gets Revised Lower

I expect the trend in the utilization rate to accelerate as the recovery in the overall U.S. economy and manufacturing sector picks up momentum later this year and through 2014. And the growth in demand for new molds and tooling will also accelerate shortly thereafter. It is too early to tell when or even if this indicator will ever get back up to the 85% level. I will continue to watch it closely and report on its progress.

Read More"Made in the USA" Certification?

Come find out what this is all about at amerimold expo on June 13 when a "certified' company takes the show floor to present "Made In The USA: Supporting The Plastics Industry – The Timing Is Right!" How one moldmaker uses American pride to support our industry while getting young adults to look at manufacturing as a career.

Read MoreA Dynamic Duo Speaks!

When I first met the co-owners of 2010 Leadtime Leader Award Winner Mold Craft, Inc., I was impressed with their enthusiasm and passion for the industry. As I got to know them better, I was blown away by their technical expertise and business savvy. Come to amerimold next month to hear their company’s automation story.

Read MoreSuccessful, Profitable Mold Design

What to consider when searching for an all-in-one mold design solution.

WatchIn the Trenches: Taking Mold Repair to the Next Level

Improving mold repair efforts— whether you’re on the bench or managing—is not only a worthy goal, but also holds its own reward.

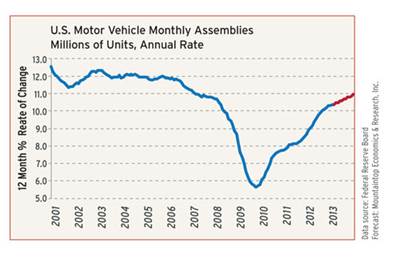

Read MoreEnd Market Report: Automotive and Consumer, May 2013

Solid Year Expected for Automotive; Solid Year Expected for Automotive

Read MoreEnhance Mold Precision by Going Five-Axis

Here’s how to manufacture large or high-precision, complex molds while maintaining efficiency.

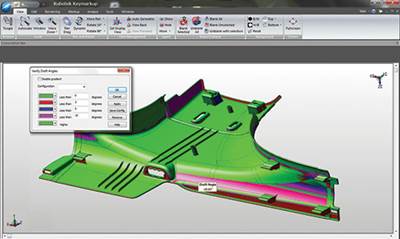

Read MoreConquering the Quoting Challenge

Adding the right multi-CAD viewer to your quoting process helps improve customer communication, secure new business, and save time and money.

WatchHow to Test Mold Design Performance

Simulation can make a company achieve its production goals faster, being more profitable.

Read MoreGetting to the “Core” of Buss Precision Mold’s Success

“We will continue to exhibit small company nimbleness to quickly adapt to our customers’ needs, while having the technology and capacity of a larger shop.”

Read MoreRamping Up to 5-Axis Programming

Steps for making the transition from three- to five-axis machining.

Read More