MMT Blog

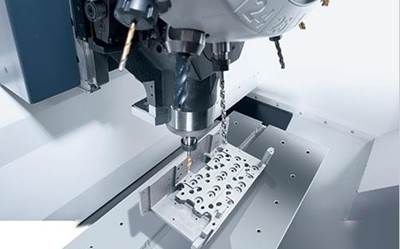

Take the Plunge: Drill vs. Mill

Strategic operation planning and cutting tool system optimization can make plunge roughing a productive, stable choice for high-volume material removal.

Read MoreStrategic Machining

Combining what they know with what they have allows these makers of investment casting molds to optimize the cutting of complex contours.

Read MoreThrowback Thursday: Growth Strategies for the U.S. Moldmaker

Some things never change. Like competition. There will always be competition, and let's face it, it's a great motivator to continuous improvement. What I've also noticed is that the ways to face the competition haven't changed all that much either. This reminded me of a four-part article series that MoldMaking Technology published back in 2001 on growth strategies for the U.S. moldmaker that is still relevant today.

Read MoreUsing CAD/CAM for Product Development

To show the value of CAD/CAM software in research and development projects, I wanted to share this story that was sent to me about an Italian plastic injection mold builder that combines craftsmanship with current technologies to offer fully integrated project management.

Read MoreDesigning Molds, Building Futures

Wes Cobb, president of Technical Design Associates Inc. in Brevard, North Carolina, is the Society of Plastics Engineers (SPE) Mold Technologies Division’s 2016 Mold Designer of the Year.

Read MoreGetting Schooled in Mold Material

I met Roland Krevitt shortly after we launched MoldMaking Technology magazine back in 1998 and he had a wealth of experience and stories to share back then. He is still sharing them today. They are mostly about his experience with mold materials, which is always quite the hot topic with MMT's readers, so I thought I'd let him share some of his experiences here with you.

Read MoreCan You Prove It?

IMC can. Technology and processes I saw during my visit proved to me that they are still living up to their motto that if you take care of your customers and give them the best products at an affordable price, you’re going to do well.

Read MoreWhat You Put Out There Comes Back to You

Surely there is truth in this headline. I’ve seen it happen with my own eyes and recently witnessed it again when I participated with the Society of Plastics Engineers (SPE) Mold Technologies Division as its Mold Maker of the Year Award was presented to Geoff Luther, owner and president of A-1 Tool Corporation in Melrose Park, Illinois. The award was well-deserved.

Read MoreRobust Process and Part Design: How Do You Ensure Success?

Using DOE with Moldflow has grown more popular in recent years because of its ability to optimize part manufacturability, according to Jeff Higgins from Autodesk, who recently conducted a webinar on the topic for MMT readers. Today, we’re offering some highlights from the webinar based on the many questions Jeff fielded and answered for attendees.

Read MoreThrowback Thursday: The Multi Approach

I consider myself quite the multitasker. Someone who is able to focus on multiple projects with equal efficiency. Well, most of the time anyway. But when it comes to mold manufacturing, multitasking can take the shop's operations to a whole new level ... every time. This look-back at our archives features an article that breaks down the barriers to multitasking and explains how it can optimize both production and profit in milling and high-speed cutting operations.

Read MoreTechnology Showcase, Hot Runners and Mold Components

Take a look at this week's slideshow to see products that make building and/or maintaining molds more efficient and cost-effective.

Read MoreWest Michigan AMBA Finishes Successful Supplier Night Fundraiser

First Supplier Night event is a success for the American Mold Builders West Michigan Chapter.

Read More