Strategic Machining

Combining what they know with what they have allows these makers of investment casting molds to optimize the cutting of complex contours.

Molds aren’t always for plastic injection molding, although plastics figure prominently whenever the topic of building molds is raised. When companies require metal parts or components whose shapes are very complex, it can be impractical, if not impossible, to machine them efficiently and economically. This is where South Coast Mold Inc., a mold manufacturer based in Irvine, California, can use its machining strategies to offer a solution.

The company, which was established in 1973 by Peter Novak, specializes in building and testing precision investment casting molds and tooling for alloy parts. According to his son Paul Novak, president and second-generation owner, investment casting, also known as lost-wax casting, is thought to have originated as long ago as 4500-3500 BC as a way to make jewelry and metal sculptures. It wasn’t until World War II that the process became a greatly sought-after answer for producing highly engineered, complex parts from special alloys that were not easily machined using traditional methods. (See sidebar below for an explanation of the investment casting process.)

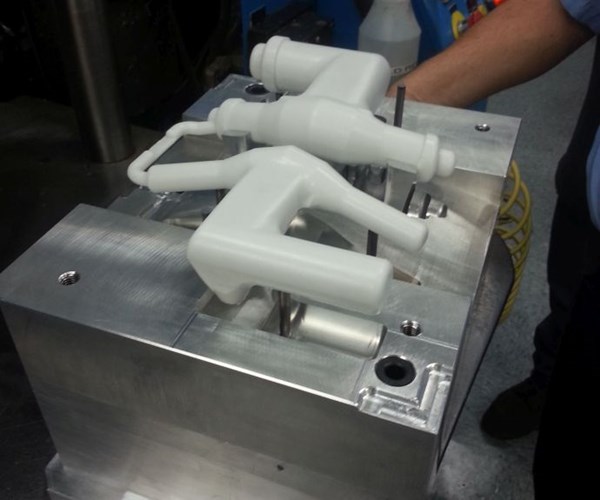

“Being able to cast around corners and blind holes, and cast pockets that cannot be machined is an advantage for our customers,” he says. “We cannot typically do this with other processes, but using wax makes it possible. We’re simply injecting wax instead of plastic, and, particularly with inside passages, there are no limitations on what the part can look like.”

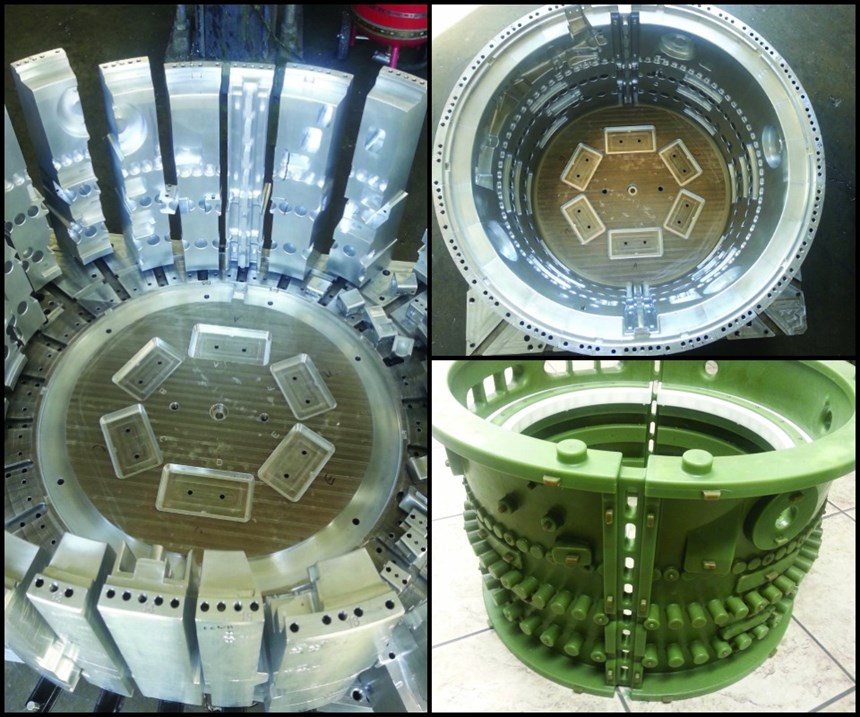

South Coast Mold builds molds for items such as blades, vanes, impellers, turbines and diffusers used in the aerospace industry, which makes up about 70 percent of the company’s customer base. Another 10 percent of the company’s business is molds for the medical industry (knee or hip replacements, prosthetics, and medical instruments), about 15 percent is for the hardware industry (valve bodies, manifolds, housings and more), and the remaining 5 percent is for firearm parts (hammers, triggers, suppressors and so on). Most of the molds the company builds have between four and eight cavities.

As with many prototype injection molds and some production mold tooling, the shop builds all of the investment casting molds out of 7000-series aluminum, with rare exceptions when a customer wants a steel core or cavity for high-production molds that are more prone to wear or have high-wear components. The average lifecycle of an aluminum investment casting mold reaches into the thousands before it requires replacement or refurbishment.

Machinery by Design

In the 43 years since its doors opened, the company has manufactured more than 7,000 investment casting molds. Novak says that a chief competitive advantage is its expertise in cutting complex contours, and that comes from experienced toolmakers, each of whom designs and builds his own molds, taking every job from concept to completion. The shop currently has eight employees, including one apprentice, and it operates out of a 7,500-square-foot building that houses 12 Mori Seiki CNC machining centers plus a wax-injection sampling machine. Supporting equipment includes drill presses, band saws, manual-engine lathes (non-CNC), small surface grinders and more.

Of the dozen CNC machines, two are four-axis and the balance three-axis. “While our 12 Mori Seiki machines are different models, they all operate the same,” Novak says. “Once a new hire or apprentice learns to operate one machine, he or she can operate all of the machining centers in the shop. One NC program will run on any machine. Furthermore, all of the machines use the same tooling, and the maintenance across all of the machines is very similar. This is no coincidence. We’ve operated this way from the beginning and it has proven to be an effective strategy. Our toolmakers work simultaneously on multiple machines and, for us, the simplicity and consistency in using uniquely Mori Seiki machines has no doubt saved us time and money in production. It’s a seamless way to operate.”

Its machining operation does not include any EDMs, which might seem very unusual for a mold builder, but it’s just part of the overall machining strategy the company follows based on the type of molds it builds. “Our foremost goal, aside from quality, is speed. Cutting, for us, is faster than EDM,” Novak says.

The shop aims to machine to a fine finish, however, which Novak says is time-consuming but necessary to minimize polishing. “Since finish-machining is unattended, CNC programs that run a little long don’t hinder us. We might need some polishing at times, but we would only spend hours, not days like with injection molds,” he says.

“The wax has to look good; that’s the main thing. No mirror polish is ever required, and what little is polished is done in-house. On those rare occasions when we are building a mold with steel inserts, we farm out the polishing work.”

Novak says this machining strategy has decreased mold build times by about 25 to 30 percent overall. Lead times for large, complex investment casting molds like those in a 10-mold package for a knee implant project South Coast recently finished can be upwards of six months, he says. Such molds might be as large as 30 inches in diameter by 40 inches long, or require press tonnage between 30 and 150 tons. More common, smaller tools might take between three and four weeks to produce, and medium-sized molds average six to eight weeks in lead time, depending on their complexity. Average cycle times for wax molds can vary a great deal due to the range of complexities, he says, but usually fall between three and five minutes, including one to two minutes of curing time.

Batch Programming

The company’s batch approach to machining of mold inserts also results in time savings. Rather than machining custom inserts individually, the shop’s toolmakers routinely cut multiple, differing inserts in the same program cycle. The lead toolmaker on a job will conduct pre-production planning and scheduling based on a customer’s specifications, then batch several programs together to run as one continuous program on one of the 12 CNC machines. Novak says the toolmakers calculate the maximum number of inserts that can be cut from one piece of raw material stock with minimal waste. For some smaller tools, top and bottom plates are machined from the same stock in the same setup, saving even more time.

“While the programming takes slightly longer, machining multiple inserts in the same setup saves us over 50 percent in machining time versus machining each insert individually,” he says. This approach also makes more efficient use of an operator’s time, enabling him to manage two to three CNC machines simultaneously, Novak says. It also allows the company to increase its lights-out machining time.

Extended Lights-Out Machining

Fully equipped with Unigraphics CAD/CAM software for mold design and for programming tool paths, South Coast Mold builds and inspects molds from solid models, and routinely runs lights-out machining every evening and, when necessary, during entire weekends. “Just this week, we ran a CNC cutting program for over 72 hours. That three-day program is not even a record for us; it’s just routine, unattended machining,” Novak says. In fact, South Coast has been running lights-out machining for 20 years, and daytime hours are regularly spent preparing for those long, overnight and weekend runs.

The network of Mori Seiki machines makes this possible. The CNC machines can run for hours unattended and then power down at the end of a programmed cycle, Novak says. Because they all are networked using distributive numerical control (DNC) technology, there is no limit to the length or size of the programs, he adds.

Additionally, the toolmakers know how to batch many small programs together to create one long program for an extended run. “In essence, these long runs simulate a second shift for us,” he says

According to Novak, the company adopted this strategy of lights-out machining two decades ago, when it had a lot of cutting work to do but not a lot of machines to meet expected deliveries. “We tried running at night, and it was amazing to come into the shop the next morning to see a finished mold segment, so we continued to do more machining over nights and weekends, developing ways to increase output,” he says. “Now, it’s become a key capability because it greatly improves delivery.”

Moving Machining Forward

In the near term, South Coast Mold plans to continuing working on standardization of setups and custom components used for building investment casting molds. Long term, Novak says a five-axis machining center is definitely in the cards for faster machining of aerospace parts like blades and airfoils, for example. Another motivating factor for this purchase is the time savings that comes from the ability to eliminate multiple setups on each job. “It’s quite possible that a five-axis machine can replace two standard CNC machines,” he says, making it clear he’s already begun to research his options.

Related Content

OEE Monitoring System Addresses Root Cause of Machine Downtime

Unique sensor and patent-pending algorithm of the Amper machine analytics system measures current draw to quickly and inexpensively inform manufacturers which machines are down and why.

Read MoreHow to Produce More Accurate Molds and Reduce Rework

Patented micro-milling process for manufacturing steel plate flat and parallel helps mold builders shorten mold build times and increase accuracy.

Read MorePredictive Manufacturing Moves Mold Builder into Advanced Medical Component Manufacturing

From a hot rod hobby, medical molds and shop performance to technology extremes, key relationships and a growth strategy, it’s obvious details matter at Eden Tool.

Read MoreHow to Eliminate Chatter

Here are techniques commonly used to combat chatter and guidelines to establish a foundation for optimizing the moldmaking process.

Read MoreRead Next

How to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreHow to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

.jpg;maxWidth=300;quality=90)