MMT Blog

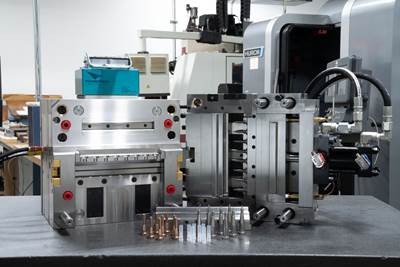

Leadtime Leader Q&A Maximum Mold Group

MoldMaking Technology invited the owner of our 2018 Leadtime Leader winning shop to share his thoughts on his die-cast die work.

Read MoreNew Tax Rules for Employee Parking Expenses

The qualified transportation fringe with the greatest impact on mold builders is qualified parking provided to their employees at no cost.

Read MoreManaging Manufacturing Cyberattacks

Improving your shop’s preparedness to deal with cyberattacks includes awareness and tools to stop them before they start.

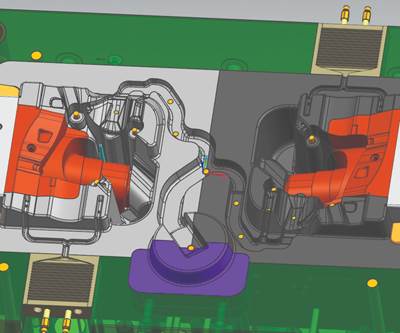

Read MoreHow to Improve Melt Distribution with Diffusion-Bonded Manifolds

Diffusion bonding for manifold manufacturing offers design freedom for optimizing hot runner melt distribution, reducing color change-over time, cavity-to-cavity weight variation, peak injection pressures, melt degradation, and resin flow stress.

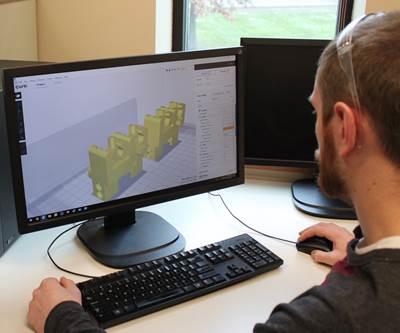

Read MorePutting 3D Printing to Work

Micro Mold and Plastikos together have invested more than $400,000 in technologies and processes related to 3D printing and reverse engineering over the last three years.

Read MoreExperience, Knowledge Base, and Creativity Give Tri-Par An Edge in Molds for High-Flow Material Parts

Expertise in building molds for parts made from highly-engineered materials and automation for molding gives Tri-Par Die and Mold Corp. key mechanisms for growth.

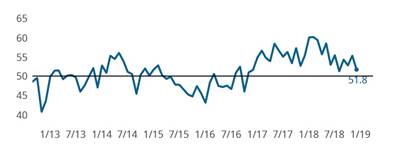

WatchPackaging Growth Indicates Strong 2019

As the plastics industry adjusts to 2018’s higher new orders volumes, capital expenditures in the industry have increased significantly.

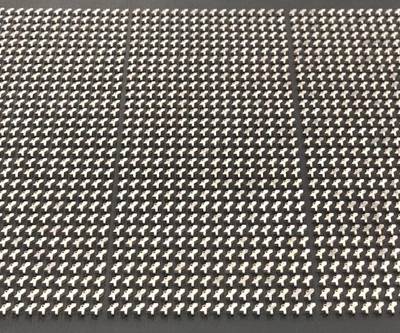

Read MoreMaintaining Mold Components

Toolroom technicians must include frame plates, frame components, and cavity tooling when developing a mold maintenance plan.

Read MoreSurface Treatments Protect Mold Finishes, Reduce Downtime and Part Failure

Surface treatment vendors are expanding their services to include more treatment options, advanced technologies and convenience.

Read MoreIntegrating the Power of AM into Injection Molding

The unique capabilities of metal 3D printing technology can complement moldmaking if the investment is justified.

Read MorePODCAST: Interview with Wepco Plastics

This shop considers the whole employee when training, and today that includes financial management at home to being a smart consumer. Learn what else makes this shop tick.

Listen