Leadtime Leader Q&A Maximum Mold Group

MoldMaking Technology invited the owner of our 2018 Leadtime Leader winning shop to share his thoughts on his die-cast die work.

When did Maximum Mold Group get involved in building die-cast dies and why?

Dave LaGrow, President, Maximum Mold Group: As an apprentice first starting in manufacturing, I was trained to build die-cast dies at the same time I was being trained to design and build plastic injection molds. A moldmaker is qualified to build both die-cast dies and plastic molds. Designing die-cast dies may be different, but if you understand tolerancing, a shop can build both. Maximum Mold Group designs and builds die-cast dies mainly for the automotive market, but also the appliance, aerospace and agriculture industries. The same markets for which we design and build plastic injection molds.

How does die-cast die work complement Maximum Mold’s injection- and blow-moldmaking capabilities?

LaGrow: Offering die-cast dies and trim dies enables the company to maintain a diverse customer base. Plus, building die-cast dies and trim dies requires most of the same equipment we use to build plastic injection molds, so no additional investment is necessary to enter the die-casting space.

How does your die-cast die work influence your mold manufacturing work and vice versa? What can be learned from one process and applied to the other?

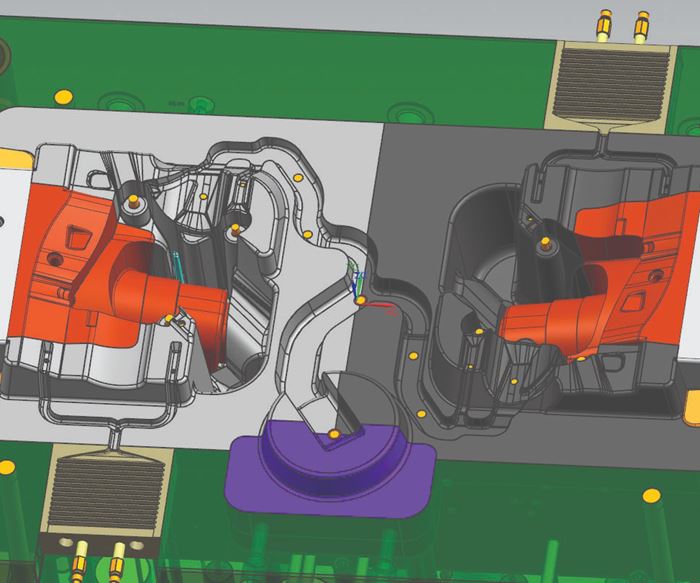

LaGrow: Die-cast die work and plastic injection moldmaking exist on opposite ends of the spectrum due to their inherent requirements, but the complexities of a modern die-cast part require an in-depth analysis of parting lines, cooling, and clearances similar to that of a plastic injection mold. Using a plastic injection moldmaking approach to our die-cast die work, such as designing dies that require less EDM work and more five-axis cutting for efficiency, allows us to build reliable tooling and to implement greater processing efficiencies.

How is the business climate for die-cast die work (as compared to moldmaking)? What does 2019 look like for this segment of your business?

LaGrow: In my opinion, the business and workforce climate is the same for both the moldmaking and die-cast die markets. Automotive is the largest market segment for both, and they each face the same challenges when it comes to competing in a global marketplace and finding engineers who have the required experience and knowledge to work in the field.

What are some specific challenges in die-cast die work?

LaGrow: A big challenge is finding better ways to cool areas in the tool where most of the heat creates failure or finding coatings and materials that withstand the heat better.

How do you stay on top of these trends?

LaGrow: The key for us is staying in touch with technology suppliers, especially with those who have special-application components for cooling difficult-to-reach areas, offer additive manufacturing equipment and services for conformal cooling and standardized components specifically for the die-cast industry.

We also speak regularly with coating and material experts to learn about new options and hear success company stories with different applications. However, sometimes, you simply need to go with your gut about a certain theory you believe might be effective and test it yourself.

What equipment and software do die-cast die makers require that is similar to and different from moldmaking?

LaGrow: The same design and toolpath software are used for injection mold and die-cast work because the same machines are used to produce the tooling. However, due to the different material properties and injection methods, the flow simulation software differs. Plastic molds use mold flow simulation software to help determine gate type and size, as well as hot runner specification. Die-cast software, such as MAGMASoft, simulates the most effective gating locations to properly fill a die-cast part while controlling solidification.

Related Content

2024 Moldmaking Insights: A Year in Review Part 1

A look back at the top moldmaking trends of 2024, as revealed through MMT's analytics. This review highlights the most popular technical articles, case studies, tips and best practices that captured the industry's attention over the past year.

Read MoreLeadtime Leader Award Winners: Hall of Fame

MoldMaking Technology’s Leadtime Leader Competition has been an ongoing award since 2003. It is a prestigious award given only to North American mold builders that go above and beyond in moldmaking. Honorees have expressed the value the Award has afforded them in exposure, recognition, morale and new business. Isn’t it time we add your shop’s name to the list?

Read MoreHonoring Excellence in Mold Manufacturing

After a brief hiatus, MoldMaking Technology’s Leadtime Leader Awards competition returns to recognize outstanding performance and innovation in the moldmaking industry.

Read MoreWho Will Win the 2024 Leadtime Leader Award? Find Out at NPE 2024!

This is it! It all boils down to this. Join the moldmaking and plastics community as MoldMaking Technology discloses this year’s award winner at 4 p.m. tomorrow in the West Hall at Booth 2143.

Read MoreRead Next

2018 Leadtime Leader Award Winner: Maximum Mold Group

Strategic acquisitions and diversified capabilities combined with a can-do, inclusive culture take this mold manufacturer to new heights.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More

.jpg;maxWidth=300;quality=90)