How to Improve Melt Distribution with Diffusion-Bonded Manifolds

Diffusion bonding for manifold manufacturing offers design freedom for optimizing hot runner melt distribution, reducing color change-over time, cavity-to-cavity weight variation, peak injection pressures, melt degradation, and resin flow stress.

As production demands rise, engineers find ways to maximize mold cavitations and minimize cycle times, which places a high demand on hot runner system performance. Designing a hot runner can be a challenging task, as melt flow paths must be geometrically and dynamically balanced yet provide sufficient space for heaters, bolt locations and valve gate assemblies, while maintaining temperature uniformity throughout each channel. This is where diffusion bonding can influence the initial design process to yield several molding benefits.

Diffusion bonding was developed and optimized for manifold manufacturing to create hot runner systems in various volumetric sizes and cavity pitches with inherent advantages for melt distribution, even with challenging applications.

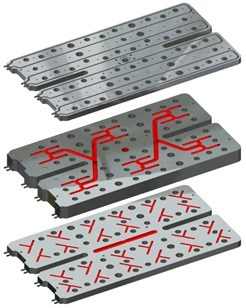

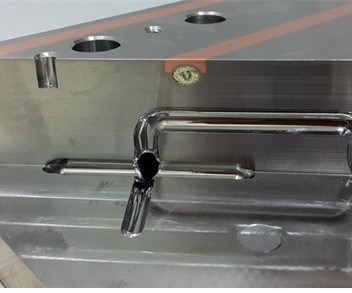

Diffusion bonding is a solid-state diffusion process that causes the atoms of adjoining steel plates to intersperse and become one. The basic procedure involves heating the plates to just below their yield point and applying high pressure to the mated plates in a vacuum environment. Once the process is completed, the result is the creation of a single piece, multi-level manifold. Diffusion bonding does not require the adjoining plates to be soldered, brazed or welded. Plus, there are no films, pastes, or bonding elements used. Instead, only the adjoining plates are in direct contact during the process.

Diffusion bonding offers more design freedom to geometrically balance melt flow to each cavity and minimize pressure drop throughout the channel layout.

Traditionally, manifolds are manufactured using gun-drilled rectilinear channels that interconnect within a steel block. However, when diffusion bonding is employed, the melt channels can be contoured and shaped to provide an optimized flow path to each cavity. The melt channel patterns are machined directly on the surfaces of multiple adjoining steel plates, mirror imaged and precisely mated in preparation for the diffusion-bonding process.

Diffusion bonding allows engineers to be creative when balancing the melt flow to each cavity. The process facilitates smooth, level transitions, eliminates sharp corners, edges, and dead spots, minimizes pressure drop throughout the channel layout, and allows the flow paths to be polished. Diffusion bonding also removes the need for end plugs, which eliminates the risk of leakage, and simplifies the entire channel layout, providing more space for bolt locations to significantly improve rigidity and durability.

Manifolds using diffusion bonding can reduce color changes over time, cavity-to-cavity weight variations, peak injection pressures (higher achievable injection rates) melt degradation/AA generation (PET) and resin flow stress of sensitive materials.

About the Author

Related Content

-

Resilience and Reflections: Moldmaking in the Evolving Economic Landscape

As moldmakers navigate this complex year marked by fluctuating business activities, and approach the upcoming year with cautious optimism, three key considerations should guide their decisions.

-

What You Should Consider When Purchasing Modified P20 Steel

When buying P20 steels that have been modified, moldmakers must be aware of the variations and key issues that affect delivery, cost and lead times.

-

Decoding Reshoring: Motivations, Challenges and Technological Influences

Harry Moser, founder and president of the Reshoring Initiative, sits down for a Q&A on the motivations behind reshoring decisions, offering insights into economic, strategic and regulatory considerations.