MMT Blog

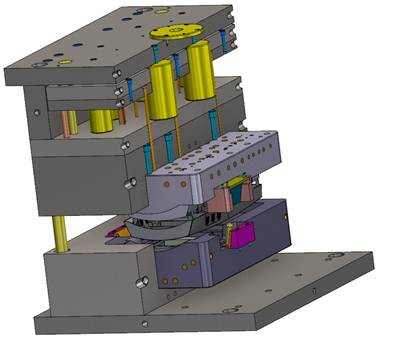

Capability to 3D Print H13 Delivers Robust Tooling

Direct metal laser sintering H13 material plays a big role in how this company has differentiated itself from the competition.

Read MoreVIDEO: How Water Flow Monitoring Optimizes Mold Production

MoldMaking Technology Editorial Director Christina Fuges and Progressive Components' Rebecca Hamstra discuss why monitoring water flow in injection molds is important.

WatchOld Friend, New Alliance Leads to Cutting-Edge Additive Capabilities

Bumping into an old friend leads Krieger Craftsmen to offer cutting-edge additive manufacturing capabilities in-house.

Read MoreMultitasking Machining Centers Double Throughput, Cut Costs

Purchasing one, then two more, multitasking machining centers has transformed the way Concours Mold Inc. builds molds.

WatchAdvanced CAM Software Streamlines Solid Modeling, Toolpath Creation, Verification and Connectivity

Advanced CAD/CAM improves performance of cutting tool designs, probing, process simulation and verification and data gathering and monitoring.

WatchA Pulse Check on AM Among Moldmakers

MMT Editorial Director Christina Fuges conducted an informal survey to gauge the growing level of interest, understanding and use of 3D printing and additive manufacturing technologies in the mold manufacturing community.

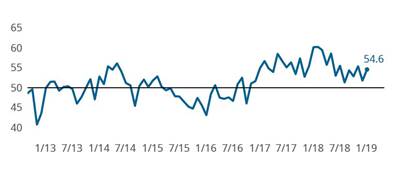

Read MoreThe Impact of International Trade Policy on Mold Manufacturing

The first step to impacting policy decisions is staying current with issues such as the U.S.-Mexico-Canada Agreement and U.S./China negotiations.

Read MoreA European View on AM: Rethinking Injection Molds

Overseas business models and applications of metal additive manufacturing promise to improve or invent functionalities integrated into molds and tools.

Read MoreRedefining Learning Labs

Training facility partners with a local North Carolina community college to challenge advanced manufacturing students to design parts, which will then be converted into mold designs for the training facility.

Read MoreSharing a Common Challenge: Workforce Development

Solving the ongoing skilled labor shortage is not only a moldmaking problem, it’s a manufacturing problem. And MoldMaking Technology’s parent company, Gardner Business Media, manages several brands covering the many facets of manufacturing, so we thought it would be cool, and interesting, if each team developed content on workforce development at the same time, so we could share it all with you.

Read MoreInspection/Measurement Software Helps Hyatt Die Cast and Engineering Reduce Costs While Increasing Efficiency and Quality

Hyatt Die Cast and Engineering Reduces Manufacturing Costs While Increasing Efficiency and Quality with Integrated Inspection/Measurement Software.

Read More

.JPG;maxWidth=400;quality=70)