3D printing has often been portrayed as a natural complement to injection molding. After all, injection molding is a high-leverage manufacturing process where extremely high tooling costs are offset by low unit costs at high volumes. Additive manufacturing (AM), particularly where metals are concerned, has presented the balancing value proposition with tooling and setup costs representing a relatively low figure in comparison to the steep per-part variable costs. However, innovation in these two fields has presented an intriguing combination of the technologies: using AM technology to produce molds and mold inserts.

Some of the advantages to this approach closely mirror the advantages of 3D printing end-use products or components. For example, required changes are easier with printed mold inserts than with CNC-milled parts; highly complex, conformally-cooled mold inserts are easier to develop using AM; and, the cost of a 3D-printed mold insert can be significantly lower than a traditionally-manufactured mold.

Adding Up the Benefits

Let’s take a closer look at a few key benefits of additively-manufactured molds and mold inserts. One of the principal advantages of 3D printing in comparison to any traditional manufacturing method is the ease of design iterations for engineers. In moldmaking, this advantage may be even more important because of the fixed costs associated with a CNC-produced mold. Given that setup costs can range from $10,000 to more than $100,000 for a ready-for-use mold, changes needed after their production can be very expensive. With AM, significant changes to an initial insert (or standalone mold) are possible with only CAD file adjustments.

Another point to consider is that combining AM and injection molding in this way allows prototyping that mimics full production runs. For example, if a shop uses 3D-printed mold inserts for prototyping, they can use the same materials and process that they will ultimately use for production without the risk of a $100,000 restart. For parts that are destined to be injection molded at scale, AM gives designers the ability to test their process in near-identical conditions. If it becomes apparent that changes are required, the mold can be adjusted quickly and inexpensively.

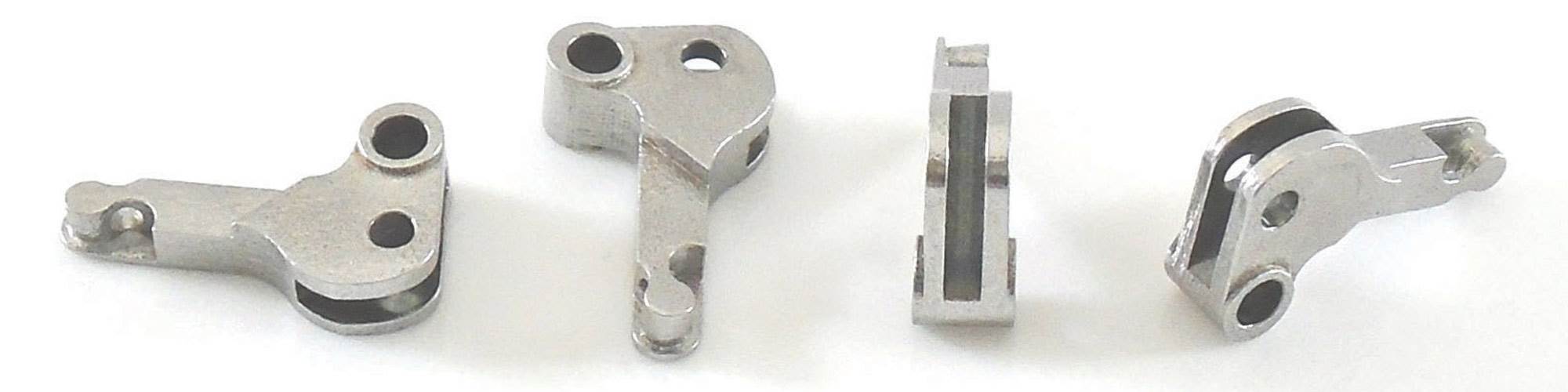

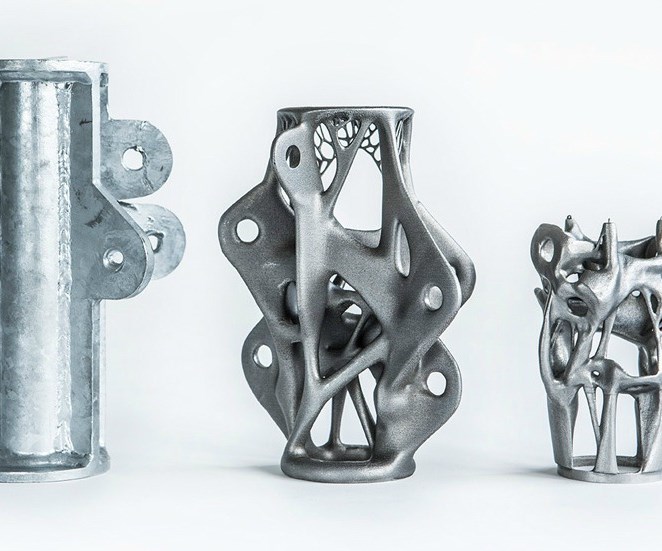

Also, not every type of component is possible using a traditionally-manufactured mold. For example, some three-dimensional designs are simply beyond the reach of CNC machines to create. Part integration or internal channels that would be impossible with any other technique can be built into the design of a 3D-printed insert and transferred directly to the mold. This process produces parts that are good cost or volume candidates for injection molding to help determine the functionality advantages of designing for AM (DfAM).

There’s also removability to consider. Some conventional two-part mold designs make getting the actual component out of the mold impossible. One innovative technique shops use to combat this issue involves using a 3D-printed plastic part to create a ceramic mold that can then be used to produce metal parts. The original plastic part melts away when the ceramic mold is heated. Metal is then injected into the resulting cavity during the transition to production.

Perhaps the most significant design improvement that AM can bring to mold manufacturing does not involve the final component. Cooling channels, which are simply channels built into a mold to allow air to circulate and cool the molded product, are straight in conventional molds. 3D printing has enabled engineers to design and build molds with conformal cooling channels that are engineered to contour around the shape of the part. This advance enables much faster cooling times, which shortens the overall cycle time needed to produce a part by injection molding.

A well-engineered conformal cooling system can potentially cut cycle times by between 20 and 40 percent. The implications of such an efficiency gain are enormous. They translate time savings into money, making 3D-printed conformal-cooled inserts a real game-changer. It’s not a magic bullet, as significant research and engineering are required to introduce conformal cooling channels, but the transformational potential is real.

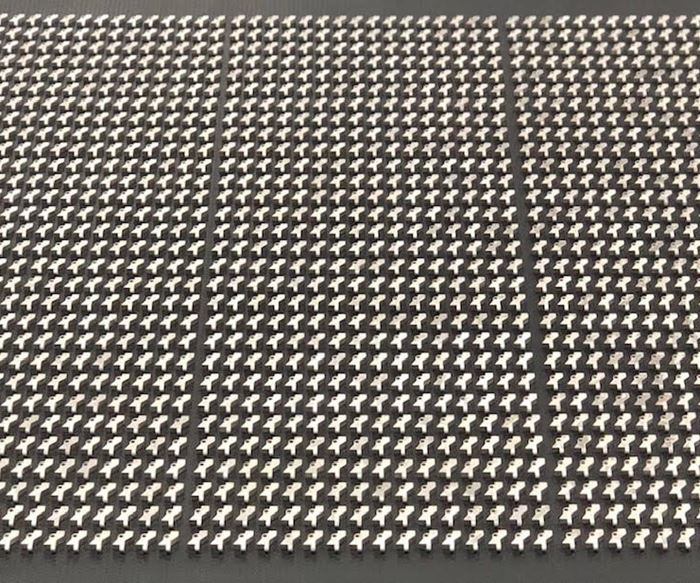

As a rule of thumb, low-run components produced using a 3D-printed mold insert will be less expensive on a per-part basis.

Justifying the Investment

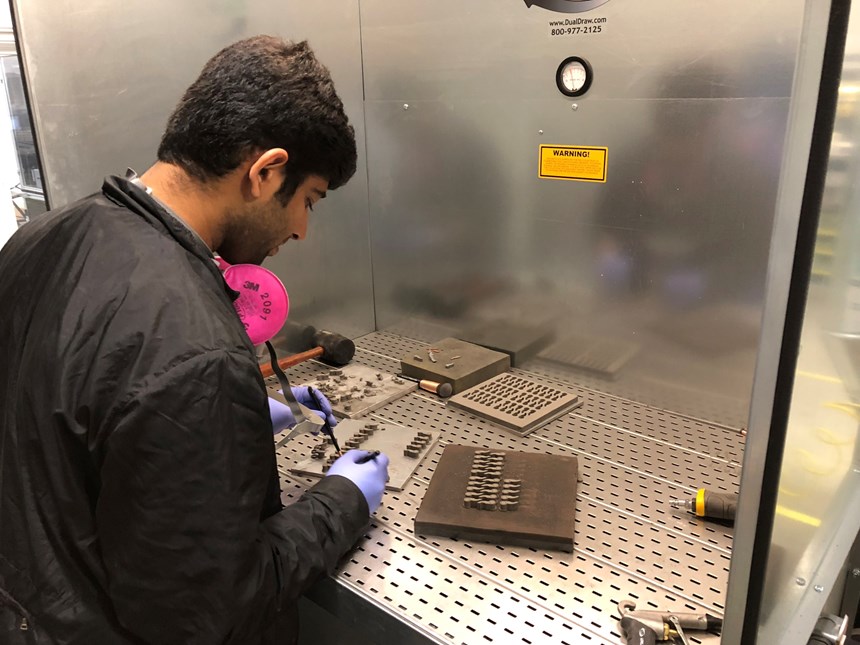

However, using metal AM in moldmaking involves a Goldilocks calculation to get “just the right amount.” First, a shop must understand that a printed mold will never match a machined mold’s structural integrity because of the limitations of 3D printing materials. Machined molds can be made from super durable metals that are often outside the scope of what is possible with 3D printing. Therefore, a shop must take this into consideration when choosing metal 3D printing over CNC machining.

Next, the application must be right for it to make economic sense. The production volume must be appropriate, the materials used must have a high resistance to heat and pressure, and the parts ultimately produced must possess a certain level of complexity to justify a flexible design process.

If a shop meets these criteria, the savings in both time and money can be significant. As a rule of thumb, low-run components produced using a 3D-printed mold insert will be less expensive on a per-part basis. The mold material, the molded material, and the use of a mold insert or a standalone mold determine if a 3D-printed mold will last for as few as 10 or as many as 1,000 units.

In some ways, the limitations that hamper metal 3D printing in direct part production still constrain its adoption in mold manufacturing. Therefore, AM in moldmaking is still young and developing, but now is the time for innovative mold manufacturers to get a leg up on the competition. New materials are being introduced to the metal AM landscape almost daily, and improvements in this area will translate directly to the potential effectiveness of printed molds.

About the Author

Matt Sand

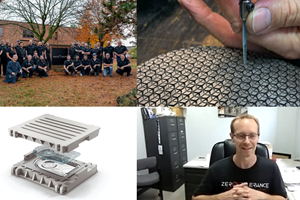

Matt Sand is president of 3DEO.

For More Information

Related Content

3D Printing Technologies for Moldmaking Applications

3D printing technologies, from conformal cooling to complex mold building, are making an impact on the moldmaking industry, one innovation at a time.

Read MoreHow Hybrid Tooling Accelerates Product Development, Sustainability for PepsiCo

The consumer products giant used to wait weeks and spend thousands on each iteration of a prototype blow mold. Now, new blow molds are available in days and cost just a few hundred dollars.

Read More4 Keys to a Successful Mold-Building Operation, The Latest Mold Design Tips & More

MoldMaking Technology is off to a strong start this year with mold design tips, key considerations for running a mold-building “business,” polishing pointers for ribs and more. Check out our list of top-viewed articles from January and see what catches your eye.

Read MoreIn "Hybrid" FIM Process, 3D Printing Complements Injection Molding

Alpine Advanced Materials used a desktop 3D printer and the freeform injection molding process to reduce prototype tooling production time and cost for its customers.

Read MoreRead Next

How to Use Continuing Education to Remain Competitive in Moldmaking

Continued training helps moldmakers make tooling decisions and properly use the latest cutting tool to efficiently machine high-quality molds.

Read MoreHow to Use Strategic Planning Tools, Data to Manage the Human Side of Business

Q&A with Marion Wells, MMT EAB member and founder of Human Asset Management.

Read MoreReasons to Use Fiber Lasers for Mold Cleaning

Fiber lasers offer a simplicity, speed, control and portability, minimizing mold cleaning risks.

Read More