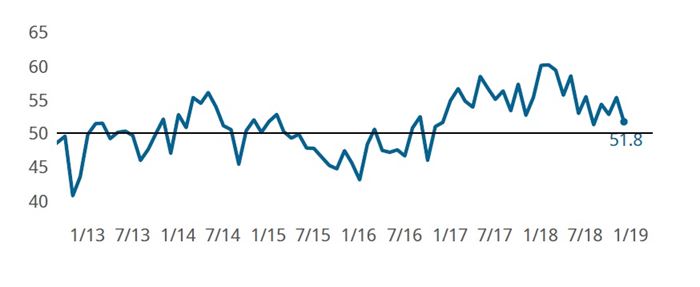

Moldmaking Index Sets Records in 2018

December 2018 – 51.8

Ending the year at 51.8, the Gardner Business Index (GBI): Moldmaking expanded at a slower rate than in recent months. During the second half of 2018, the Index recorded oscillating highs and lows that suggest growth has slowed from the higher rates experienced in 2017 and the first half of 2018. Compared to the same month one year ago, the Index has fallen 6.7 percent.

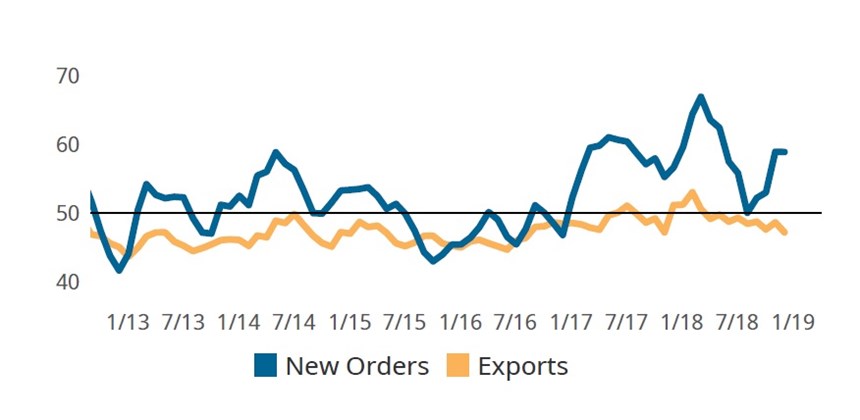

Gardner Intelligence’s review of the underlying data for the month reveals that new orders, supplier deliveries, and production lifted the Index (a calculated average of the components) higher. In contrast, backlogs, employment, and exports pulled the Index lower. Both employment and exports contracted in the latest month.

The Moldmaking industry continues to report that supplier deliveries are expanding above historical long-run rates. Gardner believes that recent months of above-average supplier delivery readings are a result of the unprecedented growth in new orders during 2017 and early 2018. Supply chains may still be responding to the large inflow of new orders from this earlier period. If this is the situation, coordination between suppliers and the mold industry in 2019 will be important such that inventories are properly adjusted and the industry can smoothly transition to a more sustainable growth rate.

December should also be noted for ending the longest period of consecutive employment growth in the history of the Moldmaking Index at 25 months.

The prior record of 11 months was established in 2012.

For More Information

Stay ahead of the curve with Gardner Intelligence.

About the Author

Michael Guckes is the chief economist for Gardner Intelligence, a division of Gardner Business Media (Cincinnati, Ohio, United States). He has performed economic analysis, modeling and forecasting work for nearly 20 years among a range of industries. He is available at mguckes@gardnerweb.com.

Related Content

-

November GBI Saw a Drop in Moldmaking Activity

The moldmaking index experienced a high degree of accelerated contract, primarily driven by production, new orders and backlog readings.

-

Moldmaking Activity Returns to Accelerated Contraction

February’s index dropped from the more positive readings seen in January, landing on par with July 2023 and remaining in contraction mode.

-

Moldmaking Activity Accelerated Contraction in July

July’s moldmaking index accelerated contraction for the third month in a row, though the magnitude was considerably less than last month.

.jpg;width=70;height=70;mode=crop)