MMT Blog

Amerimold 2019 Attendees: Map Your Show to Maximize Your Time

You have two days to see more than 200 exhibitors, see demos, attend technical presentations and a workshop. How? Map Your Show.

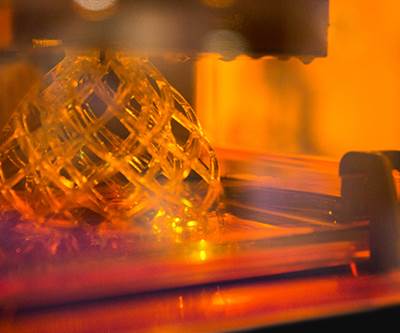

Read MoreAmerimold 2019 Update: What You Should Know about Additive Manufacturing for Conformal Cooling

This panel discussion will present in detail the different AM technologies available today, their advantages and disadvantages, and specific ways to implement these technologies without issue.

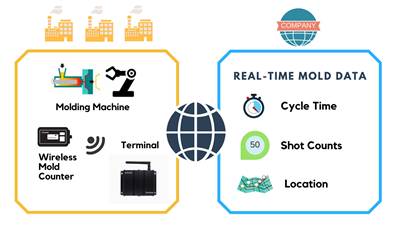

Read MoreMachine Learning for Mold Monitoring 101

Outsourced tooling supply chain management system offers data automation, more in-depth tooling analytics and performance trend measurements.

Read MoreMicromilling Demands Optimal Tool Tip Geometry

Advanced tool tip geometries ensure free-cutting properties necessary for chip consistency and long tool life in micromilling applications.

WatchHighly-Automated Tool Shop Achieves Efficient, Precise Medical Device Manufacturing

When a basketball player needs a knee replacement, standard implants simply won’t do. With a total of 18 different additive manufacturing systems, the Aesculap division of medical company B. Braun is the place to go to have custom implants printed to size. However, the highly-automated tool and mold shop has much more to offer when it comes to producing injection molds, complex progressive dies as well as prototypes and fixtures for series production.

Read MoreAdditive Manufacturing Workshop for Plastics at Amerimold Announces Complete Program

The additive and subtractive worlds of manufacturing actually do play nicely together, which is why MoldMaking Technology has always covered the various technologies. In recent years advances in 3D printing and additive manufacturing have really picked up, so this year I helped organize a lineup of presentations for our Additive Manufacturing Workshop for Plastics taking place during Amerimold this June.

Read MoreAutomation and Apprenticeships?

We talk a lot about automation. Automation involving pallet changers, tool changers, work cells, and robots. But what does automation have to do with apprenticeships? As it turns out, plenty.

Read MorePODCAST: Interview with Gardner Intelligence

MMT Editorial Director Christina Fuges sat down with The Manufacturing Alliance Podcast to get to know Michael Guckes, the Chief Economist of Gardner Intelligence who brings his monthly Index and Industry Reports to the brand.

ListenFree Amerimold Workshop: Developing Talent from Within: An Inside look at Westminster Tool’s Talent Development System

MoldMaking Technology gave the industry a taste of one small mold manufacturer’s unique approach to solving the skills gap with a feature article and video, now come to Amerimold to meet the 2014 Leadtime Leader Award Winner and Westminster Tool's Director of Talent Development, Kylee Carbone, who helped develop this successful strategy and take a deeper dive into how it all works.

Read MoreHow to Better Balance Family Molds

A servo-driven valve gate can provide superior processing for family molds with significant variances in part sizes and volumes.

Read MoreVIDEO: How Five-Axis Continuous Machining Can Advance the Manufacture of Complex Molds

MoldMaking Technology Senior Editor Cynthia Kustush interviews Greg Pozzo, applications team leader for Makino, to learn more about the company's introduction of five-axis continuous machining and its benefits for moldmaking.

WatchMold Shops Value Social Media for Branding, Reach and Recruitment

Mold builders share their approaches to social media, what works and why using the medium is so important.

Read More